Spontaneous Design in Industrial Shopfloors

Ana Correia de Barros *, Rúben Moutinho, Inês Magalhães, and Catarina Correia

Fraunhofer Portugal AICOS, Porto, Portugal

Although the work of operators in industrial shopfloors tends to be thought of as monotonous and devoid of creativity, ethnographies of work have documented examples where this is not always the case, finding cases of inventions by operators while at work. In design research, the study of spontaneous design, i.e., design made by non-designers, has looked into communities defined by geography, socioeconomic status, or abilities to inform design researchers and practitioners alike about users’ needs and aspirations, but has not explored the context of industrial shopfloors. However, studying spontaneous design in industrial shopfloors, namely what motivates them and how they are crafted, could be a way of informing the better design of shopfloor equipment to ultimately improve work conditions. We conducted an investigation in the shopfloors of 11 factories in Portugal across seven industry sectors, which rendered 205 examples of spontaneous design. Our analysis of these examples denotes that workers engage in spontaneous design to improve ergonomics, performance and product quality, having as underlying values the quests to save time, material and equipment. We argue that studying spontaneous design in industrial shopfloors can be a form of user research to inform better workplace design in the future.

Keywords – Appropriation, Manufacturing, Spontaneous Design.

Relevance to Design Practice – The results support design researchers with a process for user research based on artifact analysis of spontaneous design.

Citation: Correia de Barros, A., Moutinho, R., Magalhães, I., & Correia, C. (2025). Spontaneous design in industrial shopfloors. International Journal of Design, 19(1), 59-75. https://doi.org/10.57698/v19i1.04

Received November 22, 2023; Accepted February 23, 2025; Published April 30, 2025.

Copyright: © 2025 Correia de Barros, Moutinho, Magalhães, & Correia. Copyright for this article is retained by the authors, with first publication rights granted to the International Journal of Design. All journal content is open-accessed and allowed to be shared and adapted in accordance with the Creative Commons Attribution 4.0 International (CC BY 4.0) License.

*Corresponding Author: ana.barros@fraunhofer.pt

Ana Correia de Barros is a senior design researcher with professional experience in industry, academia, and the public sector. Ana’s initial training was in industrial design, followed by a PhD in industrial engineering and management, with additional specializations in ethnography and business design. Currently, Ana is at Fraunhofer Portugal AICOS, a research center on digital technology, as Head of Human-Centered Design, leading a multidisciplinary group of designers, engineers, and clinical researchers. Ana’s research focuses on inclusive, spontaneous, and participatory design in the fields of health and wellbeing, both at home and in work environments.

Rúben Moutinho received a BSc degree in product design from the University of Aveiro, and an MSc degree in product design from the Polytechnic Institute of Viana do Castelo, both in Portugal. Since then, he has been involved in some startups and companies based in Portugal and the USA on medical devices, cooking machines, research and development of small appliances, clothes, and cutlery. Currently, Rúben is an industrial designer at Fraunhofer Portugal AICOS within the Human-Centered Design department.

Inês Magalhães is a product designer who co-authored this paper as part of her MSc research with Fraunhofer Portugal AICOS in the Human-Centered Design department. Inês holds a bachelor’s degree in product design from ESAD Matosinhos. She also had the opportunity to study abroad on an Erasmus program in Barcelona, where she added other areas to her knowledge, such as communication.

Catarina Correia is a communication designer who worked as a design researcher at Fraunhofer Portugal AICOS until 2023. With a BA in Design from Aveiro University and a postgraduate course in digital typography from ESAD (Porto), she has also worked in cities such as Mexico City or London, where she got her MA in Communication Design from Central St. Martins. Catarina is interested in design and identity, design and emotion, social innovation, user-centered design, and inclusive design.

Introduction

The workplace has been a traditional domain of intervention for design, from the design of furniture, equipment (tools, machinery) and interiors (Myerson et al., 2010) to the design and critique of digital technologies that manage work (Cheon, 2023; Spektor et al., 2023). The need to design for the workplace was accompanied by research to understand it, leading to a variety of studies ranging from understanding territoriality practices (Brown, 2009) and how workers use equipment (Bannon & Bødker, 1989), to exploring how well-being at work could be promoted through appropriate design of workplace technology (Laschke et al., 2020).

Despite significant advances, industrial settings are underrepresented in these kinds of studies. A possible explanation might be that these settings are comparatively more challenging to access and research (Ardito et al., 2014; Cheon & Khovanskaya, 2024). However, industrial shopfloor workers are historically underprivileged when it comes to working conditions, being subjected to demanding and dangerous jobs (Govaerts et al., 2021), which shows the pertinence of research to inform appropriate design for industrial settings. Furthermore, manufacturing work has witnessed periods of significant changes which have impacted workers; the last one being the introduction of computers in the workplace (Zuboff, 1989). Currently, the changes brought about by digitalization and connectivity are expected to, again, significantly impact how people work, requiring new designs of interfaces and interactions. However, although a lot of research has been centered on technology, there is scarcer research centered on workers’ practices of interacting with artifacts, which is critical to informing design (Bannon & Bødker, 1989).

A counterargument is that the digitalization process will cause industrial shopfloor workers to be replaced by machinery and software, therefore rendering obsolete the investment into designing equipment that is easier, safer, or more rewarding for workers to use. This strand of thought also assumes that industrial shopfloor work is simple and repetitive, with no leeway for creativity (Pfeiffer, 2018). However, this view is questioned by observational research, which reveals that manual work in industrial shopfloors is highly complex in terms of embodied and tacit knowledge (Fisher & Botticello, 2018; Stein, 2021; Zuboff, 1989), which, by definition, is difficult to build, capture, and replace—a measure of that complexity being the number of years required for an industrial operator to become a specialist (Pfeiffer, 2018). Adding to this complexity, researchers doing observations of skilled and experienced workers have found signs of creativity among operators in the form of inventions or adaptations made to tools and processes, ranging from maintenance workers of photocopier machines (Orr, 1996) to shopfloor operators in diamond (Cross, 2012) and furniture (Juravich, 2017) factories. Documented by researchers in anthropology, sociology, and ergonomics, these inventions were, in most cases, not the main subject of their research, but analyzed as a way to understand a phenomenon of worker agency. In existing literature, worker inventions seem to be motivated by workers’ intention to improve work equipment towards efficiency, effectiveness (Cross, 2012; Juravich, 2017; Narimoto et al., 2020; Pfeiffer, 2016), satisfaction (Lynch, 2012) and safety (Narimoto et al., 2020). This counters the common notion that industrial equipment is always conforming to standards and, like the pre-conception about human industrial workers, with no leeway for adaptation, and also calls into question the replaceability of operators on industrial shopfloors by digital tools.

So we see that there is a body of work dedicated to fieldwork observation of industrial workers which opposes the ideas of total automation, with workers’ inventions coming about as evidence of how industrial work runs counter to prescribed work modes (Mörike, 2022), at times to improve efficiency and effectiveness, which are arguably valuable to employers as well. However, there are no systematic studies analyzing these worker inventions with the goal of understanding why it is that workers engage in this type of behavior and what characteristics these artifacts exhibit, which design researchers and design practitioners could learn from. A glimpse into this possibility is given by Fisher and Boticello (2018), who called into question the established frontiers between what is craft and what is industrial work. To do so, they brought forth evidence from an ethnographic study that showed how industrial shopfloor workers interacted with machinery in ways akin to the definition of craftwork, heavily reliant on tacit and distributed knowledge, and with interventions made to machinery so that it would meet workers’ purposes better. These types of interventions are designs made by non-designers.

Design research has been interested in design by non-designers for many years, but has tended to stay away from the world of work, especially from the world of industrial work, instead focusing more on the personal and domestic realms (e.g., Nur et al., 2019; Wakkary & Maestri, 2008). Our research contributes to this body of knowledge by seeking, documenting, analyzing, and classifying examples of such inventions—which we call spontaneous design, after Loschiavo dos Santos’ definition (2000)—on industrial shopfloors in Portugal, a country where most of the manufacturing industry is traditional, and whose recent Governments have been doing significant investments so that factories can digitalize and/or automate their processes and operations.

Analyzing examples of spontaneous design as a form of user research could be a way to let objects speak for themselves; it could help trace histories of practices within a particular environment by looking at artifact interventions left by people who are no longer at work, it could help counter the challenges of participatory design processes in demanding work environments, it could provide insights into workers’ needs and practices, and it could be a way to give visibility to workers’ inventiveness and skills, thus dignifying human work, and, with it, help to critically analyze the processes of digitalization of industrial shopfloors.

In this paper, we present the results of a study which aimed at understanding how research into spontaneous design in industrial shopfloors could be a source of information for the design of industrial shopfloor equipment. In so doing, we present the characteristics of the spontaneous design examples we found, what their purposes are, i.e., why shopfloor workers created them, how they can provide insights for designers, and how their analysis reveals aspects of workers’ values. Indeed, through the method of artifact analysis, common in anthropology (Miller, 2009), but focusing on spontaneous design examples only, we seek to demonstrate how spontaneous design can be a rich source of research for designers working in the field of industrial equipment design. The study is part of a larger research project, which has been described elsewhere (Correia de Barros et al., 2024).

Before we move into the methods, we will delve a bit deeper into the topic of spontaneous design, since the understanding of the concepts and the theories around it will be important to frame our methods and place our contribution.

Spontaneous Design

The relevance and extent of spontaneous design are demonstrated by the fact that many communities have terms to describe it, referring to the created design, the process of designing, or both. Examples are the terms desenrascanço (Portugal), jugaad (India), gambiarra (Brazil), kludge or thingamyjig (USA), cacharreo (Colombia), or halletmek (Turkey). These words carry an implicit allusion to contexts deprived of time, financial resources, market offer, or ergonomic fit (Boufleur, 2013). Similar contexts are what cause spontaneous designs to be abundant within the disabled and chronic patient communities, with the added purposes of avoiding stigma and supporting human functionality (Correia de Barros et al., 2010; Correia de Barros & Duarte, 2009; Hirsch et al., 2000; Jacobson & Pirinen, 2007; Mayer, 2007; Oliveira et al., 2015; Rosenberg, 1968).

How non-designers (or users) use, adjust, repurpose, or create new physical or digital designs has been a matter of interest in Design Studies, Human-Computer Interaction (HCI), Science and Technology Studies (STS), and other fields (Kohtala et al., 2020). This is reflected in the multitude of terms that exist within academia to describe the phenomenon, e.g., spontaneous design, vernacular design, popular design, do-it-yourself, adhocism, re-invented design, design-in-use, design by use (Botero et al., 2010; Boufleur, 2013; Brandes et al., 2009; De Bozzi & Oroza, 2002; Jencks & Silver, 2013; Kohtala et al., 2020; Loschiavo dos Santos, 2000; Von Hippel, 1976; Wakkary & Maestri, 2008). In our view, the study of spontaneous design falls into wider studies on the phenomenon of appropriation, such as the work of Akrich (1998), Dourish (2003), Dix (2007), Botero et al. (2010), or Kohtala et al. (2020). These studies, routed in STS (Eglash, 2004), are interested in how non-designers behave in relation to artifacts and how they adapt them for their own needs.

There is a body of research analyzing spontaneous design regarding different geographies, different user groups, and different categories of artifacts. Boufleur (2013) analyzed spontaneous design in financially deprived contexts in Brazil, by looking at the circumstances in which it emerged, the characteristics of the artifacts, and the motivations behind their creation. De Bozzi and Oroza (2002) documented and categorized popular inventions in Cuba, mostly within the domestic space, from analogical to electrical devices. Angelo (2003) illustrated prisoners’ inventions. Arkhipov (2006) documented homemade everyday devices in Russia, later doing the same for Europe. Jencks and Silver (2013) studied spontaneous design from products to architecture with a keen interest on the motivations behind these creations. Storni (2010) has documented how people with chronic diseases appropriate digital technology for self-care. Another example is the work by Wakkary and Maestri (2008), who did not seek to design new products but advocated for everyday domestic practices as privileged sources to understand user behavior and inform future technology design. Related to this research on human behavior to inform design is the inventory of thoughtless acts, by Jane Fulton Suri and Ideo (2005), which are indeed forms of appropriation.

In industrial shopfloors, workers adapt and build their own workstations and tools (Cross, 2012; Fisher & Botticello, 2018; Juravich, 2017; Mörike, 2022). These examples are less well documented than those related to personal realms, including coping with disability and chronic disease. Whilst there has been work exploring embodied knowledge, appropriation, and creativity in shopfloors (Maiden et al., 2017), to the best of our knowledge, there has been no research on building designerly knowledge from spontaneous design in these contexts, to inform the design of appropriate, safe, and inclusive industrial work equipment.

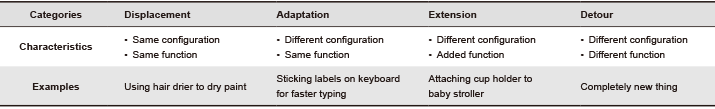

There are also different taxonomies created for the phenomenon of appropriation, as summarised in the work of Kohtala et al. (2020). In this paper, we will frame appropriation examples using the categories created by Akrich (1998) since they are based on an analysis of the degree of intervention to form and function, two dimensions which we considered would be relevant to analyze when trying to derive implications of spontaneous design analysis to design practice. Akrich (1998) proposes the categories of displacement, adaptation, extension, and detour (Table 1). Displacement involves no changes made to the product, and it occurs when one object is used with the same function for a different purpose than the one intended by the designers. Adaptation implies some changes to the product without interfering with the original function, such as changes to increase product accessibility. In an Extension, the product maintains its original functions but is changed to accumulate other functions. Detour involves the greatest degree of change from the initial product and results in a new object with a different function than the original one. To the artifacts that result from these interventions/appropriations, we call spontaneous design, as used by Loschiavo dos Santos (2000), because the term captures the meaning that these designs often emerge based on need, on what is at hand (concurring with the Lévi-Strauss’ (1966) concept of the bricoleur) and often in non-mainstream situations, as illustrated in the examples above. Such examples also show that spontaneous designs emerge within different user groups, in different cultures, and regarding different product types, from analogic to digital technology.

Table 1. Scheme explaining Akrich’s (1998) categories with examples.

Methods

The study was favorably assessed by the ethics committee of the University of Porto (reference 134/CEUP/2023). For factory recruitment, we prepared a project leaflet explaining the purpose of the project and the involvement requested by the factories in terms of time and human resources. We used a purposive sample based on prior established relationships with factories in Portugal. Factories were contacted by e-mail and/or telephone. Given the exploratory nature of the research, recruitment was sector-agnostic. Agreement to take part in the study was formalized via e-mail, and individual worker participation was formalized via informed consent forms.

Before the first fieldwork visit, the first author held a training session with the remaining authors to explain Akrich’s (1998) categories, providing examples for each. The first author also gave instructions about the importance of trying to collect data during the fieldwork about the underlying motivations for the creation of any spontaneous design examples we might come across and to try to identify the workers behind these examples.

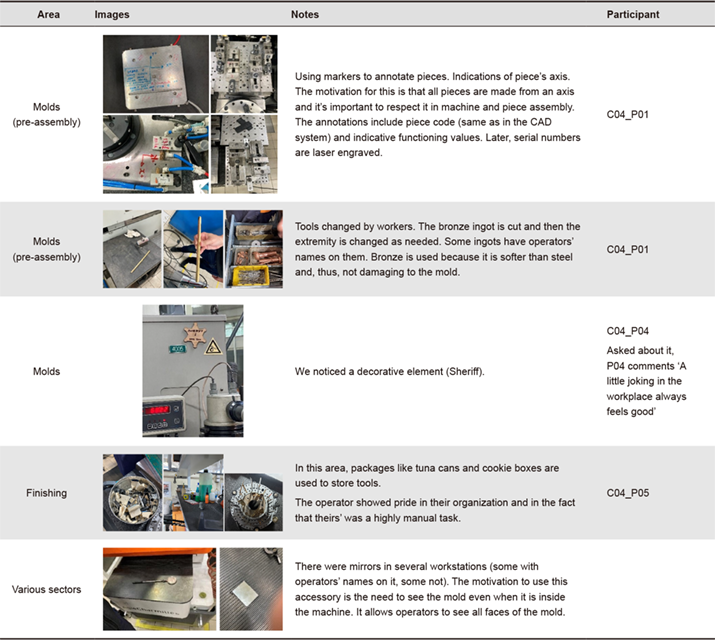

For the documentation of spontaneous design examples at the shopfloor level, we engaged in free non-participant observation, documenting the examples in photographs, videos, drawings, and notes. The choice of methods allowed us to document the data for later analysis. In fieldwork visits, factories appointed one or more employees who would tour the factory with the researchers and introduce workers who had created or adapted equipment. In collecting these data, we used contextual inquiry to provide additional context to each spontaneous design example (e.g., industry, product, materials, job tasks). To do this, we either asked questions about the artifacts to the person from the factory who was guiding us or, if possible, to the person who had created a spontaneous design that we had found.

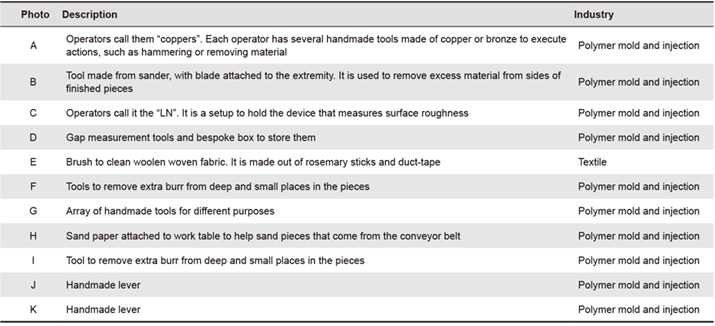

After each fieldwork visit, the research team gathered the pictures and videos in a shared folder, naming each document using a convention that was defined at project onset in order to prepare the dataset for future release in open-source. The team also produced two documents after each visit: 1) a catalog of the pictures taken, together with descriptions of each example, motivations for the creation of certain objects as described by participants or quotes from participants (Table 2), and 2) a report about the visit, where the contextual data found its place, as well as general quotes or information collected from participants, as shown in the example of the researcher’s note below:

P01 (…) states that the motivation to create these tools arises from necessity, depending on the clients and on the products they have. If they want to change machinery, they always have to talk to manufacturers first. P01 says they build the tools they need, but in a way that does not impact productivity. They also only build what is worthwhile building there—if it is cheaper to buy it outside, they won’t do it inhouse. (Notes from the report of a visit to C04, translated from Portuguese to English)

Table 2. Example of entries in the catalog created after the visit to one of the industrial units (C04). The original is in Portuguese.

After this, we used a shared workspace in MURAL (https://app.mural.co/) where we placed all photos taken according to Akrich’s (1998) categories. The categorization was made individually, and the team would meet weekly to discuss the placement of each photograph and reach a consensus. During the team’s discussions for consensus, we found the need to create two extra categories—affordances and handmade replicas—not because they were found to be new categories of appropriation, but because they seemed to reveal something about the motivations/goals of user agency, as well as about the process to do so.

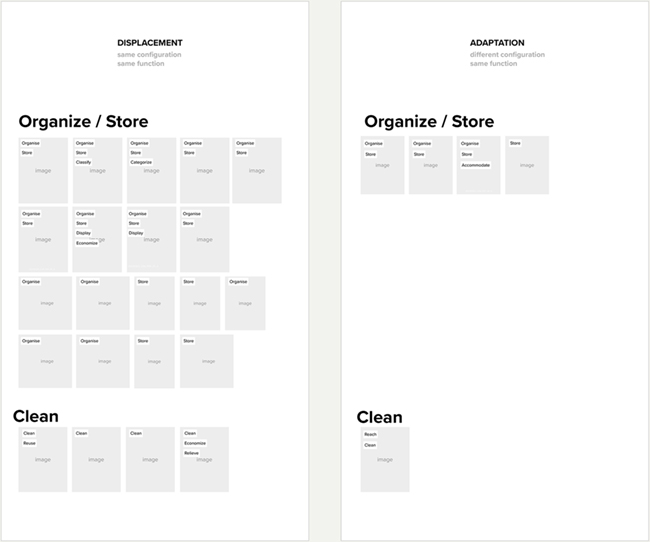

Afterward, we conducted an analysis of the motivations/goals behind each example, crossing the data from our catalogs, reports, and photographs and identifying the function of each example. Each team member assigned tags to each picture with a verb about the function of each spontaneous design example, e.g., store, protect, inform, organize. The team members discussed these tags regularly in weekly meetings to reach a consensus. Once all photographs were tagged, we grouped the photographs by tag or tag proximity within affinity diagrams (Figure 1). The result was the identification of what we called purpose categories described in the Findings section.

Figure 1. Representation of how affinity mapping was made by grouping photographs with similar or proximal tags.

Context and Participants

Industrial Settings

Eleven industrial units (from small to large) were visited for this research, all of which are located in Portugal, in the sectors of lighting (n = 1), ceramics (n = 2), metallurgy (n = 3), polymer molds and injection (n = 2), textile (n = 1), woodworking (n = 1), and cardboard packaging (n = 1). Our dataset consists of 943 photos. In the lighting sector we were not allowed to take photographs, but were given a tour by one of the employers to some areas of the factory. We did not find or document examples of spontaneous design, although we were told older operators engaged in this kind of practice.

Participants

Not all spontaneous designs found on the shopfloors could be associated with a worker because they were no longer with the factory or because the person(s) assisting the research team with the tours could not identify who had created the spontaneous designs.

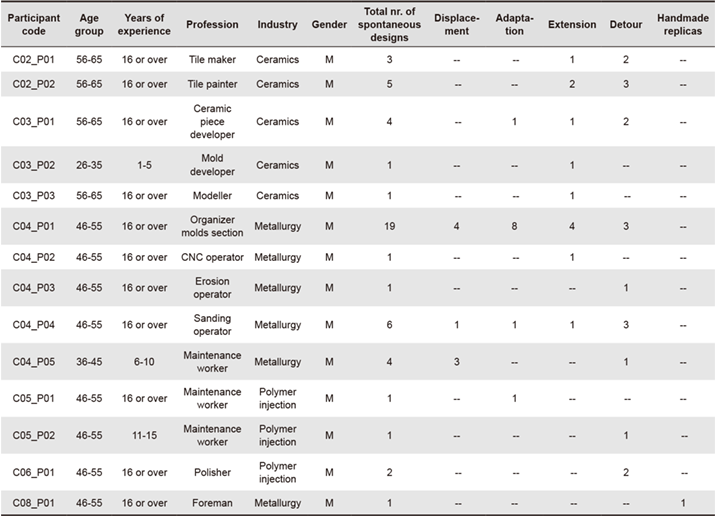

We interacted with 14 workers who were identified as creators of spontaneous designs (Table 3). All workers in this sample are male, the majority (11 in 14) have 16 or more years of experience in the job, and the majority (12 in 14) are aged 46 or older. Although the number of spontaneous designs per participant was well-distributed, there is an outlier in participant C04_P01, from whom we have identified 19 examples of spontaneous designs.

Table 3. Characteristics of workers who created spontaneous designs.

Findings

We found 205 examples of spontaneous design, which we grouped under Akrich’s (1998) categories of Displacement (n = 34), Adaptation (n = 53), Extension (n = 73), and Detour (n = 45). We have also found 24 examples of appropriation of objects for new purposes through affordances, as well as 49 examples of handmade replicas of existing objects, e.g., dustpans or step stools.

In this section, we present our analysis of the examples of spontaneous design. First, we present an analysis according to Akrich’s categories. We then explain in more detail and give examples of artifacts we categorized as affordances and homemade replicas. Finally, we present the categories of purpose that emerged from our affinity mapping based on artifacts’ functions. When possible, we illustrate these categories with photographs from our dataset, however, not all of the pictures in the dataset can be revealed to preserve confidentiality issues agreed with the factories. Two of the industrial units did not allow the photographs to be shared, and one restricted some photographs, which potentially revealed trade secrets.

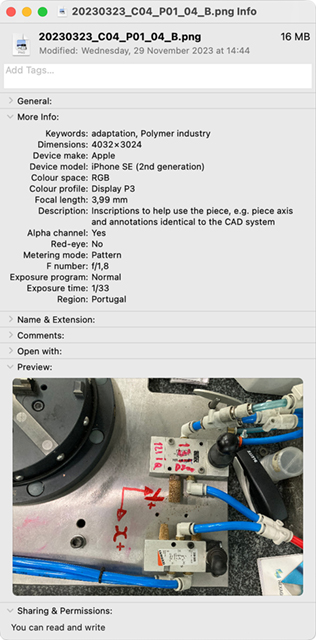

The photographs that were authorized for dissemination (696 in total) were uploaded to a public repository (Correia de Barros et al., 2023) and can be accessed free of charge. They include examples of the spontaneous designs we found, as well as other pictures of the industrial units that the team captured but which were not later categorized as spontaneous designs (such as the examples in the section of other interventions). The dataset was curated by doing the following: 1) eliminating pictures that were of poor quality, 2) editing pictures to obfuscate the identities of operators, factories, or their clients via pixelization of selected areas, and 3) adding metadata to the following fields: Creator, Description, Alt text, Keywords (used as tags for type of spontaneous design (when applicable) and industry to which the example belonged), Country and Copyright status (Figure 2).

Figure 2. An example of metadata filled in for photographs of the dataset.

Dataset available at: https://doi.org/10.5281/zenodo.10182679

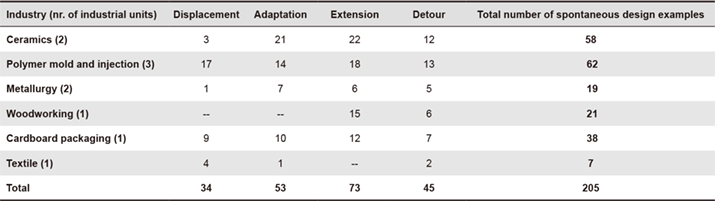

Appropriation by Type

Table 4 shows a matrix of the spontaneous design examples found according to Akrich’s categories and grouped by sector. Most of the examples fall into Extension (35.6%) and Adaptation (25.8%). The sectors of polymer injection and molding and ceramics were the ones with the most examples of spontaneous design—30.2% and 28.3%, respectively. However, we must note that these sectors are represented in our matrix with a different number of industrial units, so we cannot conclude that one sector is more prone to spontaneous design than another.

Table 4. Number and type of spontaneous design examples found per sector.

Other Types of Interventions

In this section, we provide examples of user interventions in space and in artifacts, which we documented, but did not consider as examples of spontaneous design, as per Akrich’s categories.

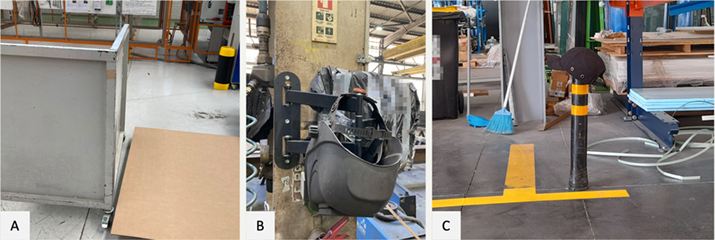

Figure 3 shows examples of what we categorized as affordances, in this case, in the sectors of cardboard packaging and metallurgy. These are situations in which operators use objects’ properties (e.g., form, texture, size, weight) to their advantage to serve a purpose other than what the object was designed for.

Figure 3. Examples of affordances: A) Heavy cart used to block cardboard plates being thrown by the machine; B); Welding glasses resting on wall-mounted structure for monitors; C) Cap resting on a protection bollard.

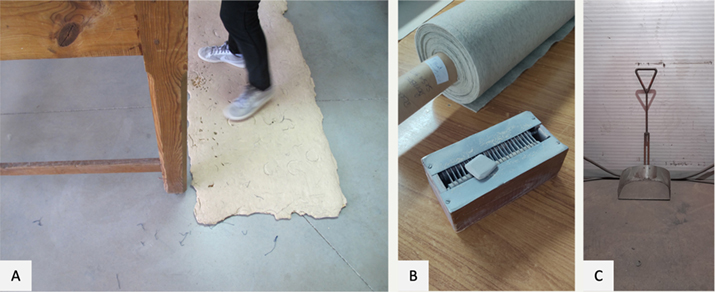

We also found several examples of what we called handmade replicas. Figure 4 shows three such examples in the Textile and Metallurgy sectors. We can see in Figures 4a and 4c how the materials used to build these replicas were leftovers of materials used, transformed, or produced in the respective industrial units. Later, when we discuss underlying values in spontaneous design, we will return to this choice of materials.

Figure 4. Examples of handmade replicas: A) Anti-fatigue mat; B) Tailor’s chalk sharpener; C) Dustpan for fillings.

Purpose Categories

In this section, we present the results from the analysis of spontaneous design examples in terms of purposes. Our affinity mapping led to the emergence of five categories of purpose, which are individually described below, along with examples of implications they bring to design.

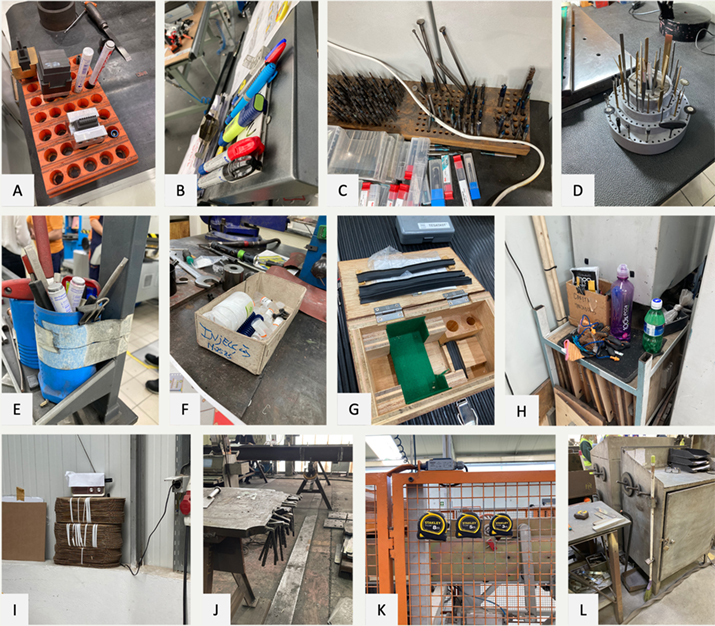

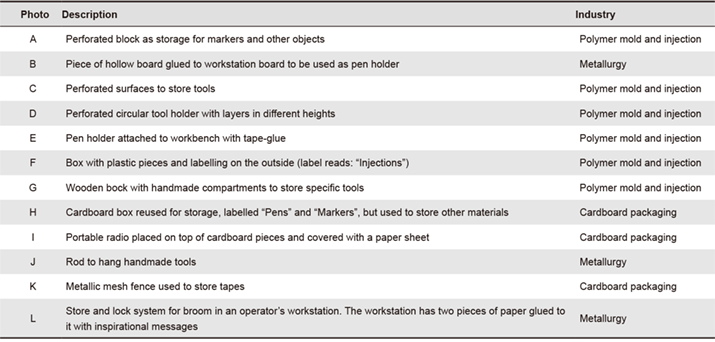

Organizing and Displaying Utensils and Materials

There is a prominence of examples where the main function is to organize/display materials and utensils on the shopfloor (Figure 5). This is done through the reuse of lidless boxes made with different materials or using rod-like elements to hang utensils within easy reach. If materials or utensils are in adapted boxes, they may have a label naming the department/area or describing the content. However, the label and the content might not match for long, as is the case with Figure 5H, where the label reads pens and markers but is actually storing something else. Labels with department names are intended to avoid missing utensils. This concern can also be noticed in Figure 5L, where a broom is seen locked to a cabinet. This cabinet example is interesting, as it also contains handwritten inspirational messages related to a specific worker, pointing at aspects of territoriality in the workplace, which is the subject of many studies (Brown, 2009).

Figure 5. Examples of spontaneous designs to organize and display tools (photo descriptions in Appendix I).

In individual workbenches, where operators need to do manual work over a flat surface to work on a piece, there were spontaneous design examples that followed a design pattern of perforated objects where tools can be inserted and easily accessed. It seems to be important that materials and utensils being organized/displayed are all visible with a glance and positioned so that they can quickly be picked up.

Most of the examples of spontaneous designs to organize/display fall into Akrich’s categories of Displacement and Extension. In the former case, there is a strong effect of the affordance to insert and even more so of the affordance to hang. Many of these instances bear similarities to thoughtless acts documented by Jane Fulton Suri and IDEO (2005).

Implications for design. Direct implications for practice are that the design of utensil and material storage at the industrial shopfloor should be versatile due to changing demands; it should promote glanceability and easy approach and use, akin to the seven principles of universal design (Mace et al., 1991).

The characteristics of the examples in this purpose category can also be reflective of efficiency practices, accountability (having one’s name inscribed in an artifact signals the owner and forces a duty of return when the artifact is borrowed), and territoriality. A story we heard about an experienced operator in one of the factories illustrates this notion of territoriality to an extreme: this worker, whose workplace was next to a door leading outside, planted his own vegetable garden and a fig tree behind that door.

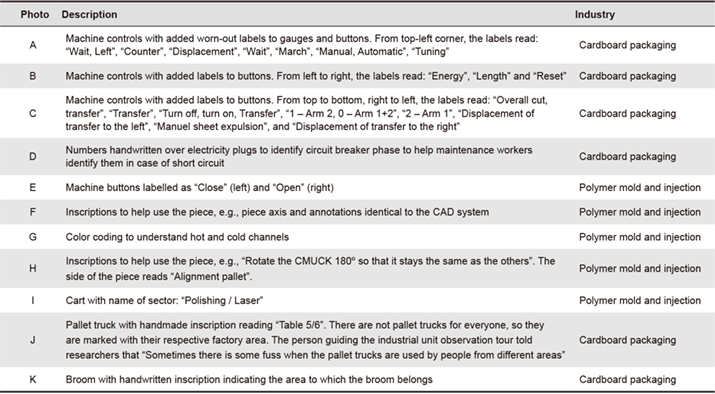

Providing Information

Having timely and concrete information is also a significant motivation for engagement in spontaneous design. In some factories, we have noticed the need to create specific information systems with codes that are learned and recognized by the workers involved. There were two instances of this: in one case, the workers developed a color convention for technical drawings of injection molds which helps represent hot and cold channels (Figure 6G); in another case, the factory created a set of icons and color codes for factory areas (e.g., operations area, storage area).

Often there is equipment with manuscript information made with markers (Figure 6F&H). There is also a need to label utensils with the worker or the factory sector name to avoid misplacement and loss. These labels might even be inscribed as warnings directly over the equipment, as in Figure 6I-K. Examples of spontaneous design in this category are the result of Adaptation and Extension, as per Akrich’s framework.

Machinery brings instructions that are not always understood by workers who need to operate that machine. For this reason, workers often place a new layer of text through manual annotations on paper tapes or embossed labels. Even if the language on machine labels is understandable, additional layers of information might still be required to provide instructions on how to operate certain parts of the machine or to provide workers with timely safety instructions. There are also instances in which the original machine does not come with all labels required, and so workers superimpose them—examples of this might be seen in Figure 6E, where two buttons were newly labeled (open and close). A variation of this is to insert redundancy in the machine, as in the case of Figure 6B, where workers have added the label energy to an on/off switch button, even though the format I/O is quite common, at least in the geography where this study took place. Some of these examples on added layers of information have the goal of protecting user safety in human-machine interaction. The category of protection, however, goes beyond information, which is what we explore in the following purpose category.

Figure 6. Examples of spontaneous design to inform (photo descriptions in Appendix II).

Implications for design. The analysis of the examples in this purpose category allows us to identify flaws with existing industrial machinery: it is often not adapted to multiple uses, multiple languages, multiple cultures, or multiple jargon. Ultimately, this flaw in design has an impact on workers’ safety and is a potentiator of errors in human-machine interaction.

Looking at implications at an organizational level, we can see that, as noted by other authors (e.g., Fisher & Botticello, 2018; Mörike, 2022), a shared understanding is critical in an industrial shopfloor and operators seem to engage in spontaneous design to facilitate this.

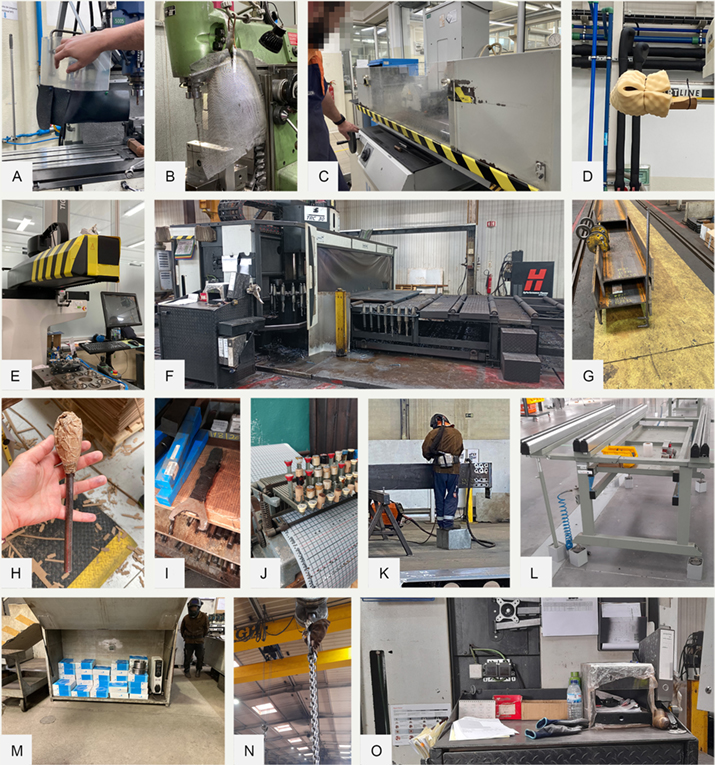

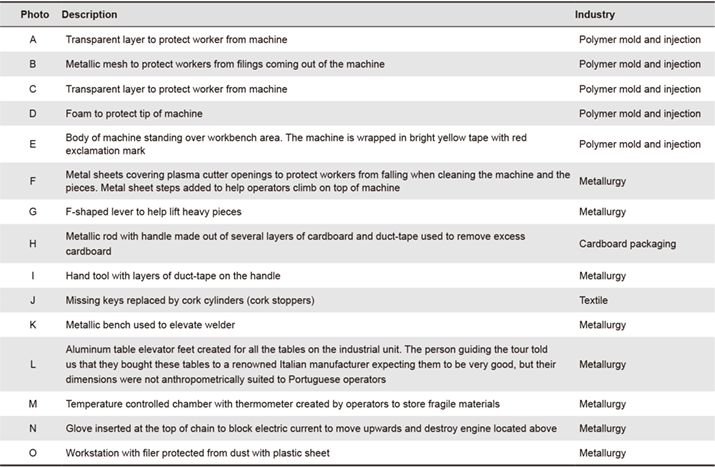

Protecting People and Equipment

Through spontaneous design, workers augment human physical and sensory abilities, improve comfort, and protect themselves physically and cognitively. In our sample, they did so through Adaptation, Extension, and Detour. Having good visibility is important for many operations, which requires workers to repurpose or reposition lights. Mirrors are repurposed to counter lack of visibility, for example, to see the rear of machines or so that operators can quickly see their own reflection in case a particle jumps into their eyes. Physical protection from poor body positions leads to changes made to seats and tables (Figure 7K or the example we saw of a worker who was using a block of extruded polystyrene on her seat as a cushion). The need for physical protection from poorly designed tool handles is often shown by extra material layers to improve grip comfort (Figure 7H&I). Workers also engage in spontaneous design to protect themselves from carrying heavy weights (Figure 7G depicts a lever for heavy steel) and add layers of information to machinery to guarantee that they are able to operate the machinery properly and to do so without exposure to physical hazards.

To protect equipment, the predominant technique is to cover it with an extra layer of material (Figure 7D, E, O). In one instance, we found the use of another layer of material (a glove) placed between two pieces of equipment to block electric current, which in the long term could damage the equipment (Figure 7N).

Figure 7. Examples of spontaneous design to protect people and equipment (photo descriptions in Appendix III).

Implications for design. Of all the categories, this is the one where we can establish more links to traditional concerns in ergonomics. Analyzing the images from the lens of the seven universal design principles (Mace et al., 1991), we can see that there are design flaws. This category of purpose reveals, for instance, that the aspect of visibility of objects and processes is often overlooked in machinery design, leading the workers to unnecessary strain and potential errors or hazards. A broader implication for design research is that workers feel compelled to protect the equipment they work with and to extend its lifetime.

Cleaning Machinery, Utensils, and Products

It is often the case that machinery, utensils, and products need to be cleaned on the shopfloor. Most of the examples of spontaneous design we found to achieve this goal were created by Displacement (e.g., using a toothbrush) or Detour so that workers could reach small and deep areas. However, we have also found an example of an Extension to a machine for continuous cleansing of a conveyor belt that works through the steady application of weight. Unfortunately, the photographs we have for this category cannot be shared.

Although not an example of spontaneous design, we found a myriad of rags in all industrial units that we visited, standing on workbenches, inside machinery, on top of machinery, or hanging from rods. This shows the prevalence of the task of cleaning as part of industrial manufacturing work.

Implications for design. Although there might be a tendency in design to consider primary functions only, this purpose category brings to light the secondary activity of cleaning, which is of relevance to both employers and employees. Equipment that is self-cleaning or easy to clean will likely bring additional value to industrial shopfloors.

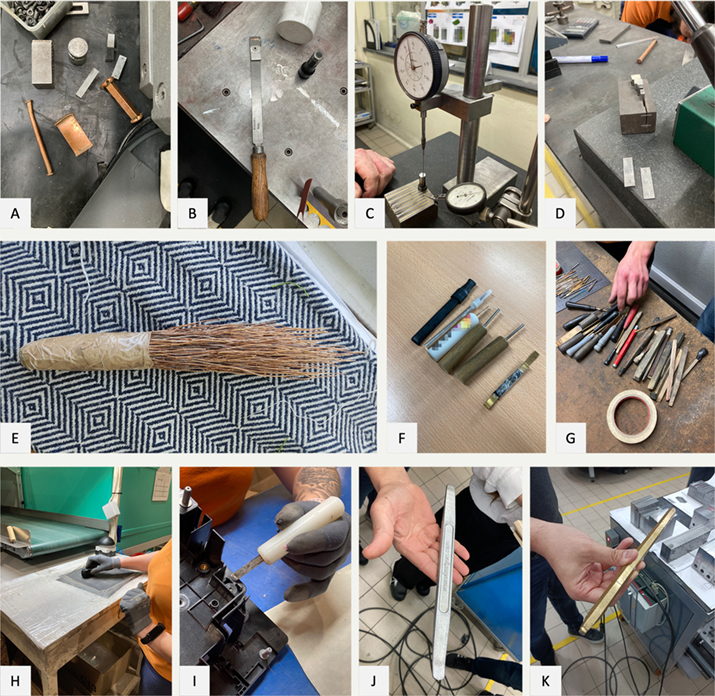

Improving the Craft

This category is made of examples of spontaneous designs created to improve workers’ performance in the job. Whilst some spontaneous design examples improve performance by efficiency, as is the case of having utensils at hand, as shown in the first category, here the examples revolve around crafting (Figure 8).

Figure 8. Examples of spontaneous design to improve workers’ performance (photo descriptions in Appendix IV).

The examples in this category are of tools usually for individual use. For example, the artifacts in Figures 8B and 8I were created to careful eliminate excess material. In the first case, the object was created by adapting a pre-existing sander with a blade. In the latter, a thin sheet of metal was added to a pre-existing handle. Figures 8J and 8K show examples of what operators call levers to move pieces in injection molding. These levers are created out of softer material, so as not to damage the pieces being produced, and are tailored by each individual worker, often having operators’ names engraved on them. The interventions can also improve the craft by improving the workflow. This is shown by Figure 8H, where sand paper was attached to a table placed underneath a conveyor belt, so that the operator could more easily sand the pieces as they came out of the conveyor belt.

There are several examples in which operators devise completely new tools based on existing artifacts (Detour) or perform Extensions and Adaptations to existing tools and machinery to improve the quality of their work, which will have an effect on the quality of the final product. Spontaneous design in this case tends to have the purposes of improving task rigor and improving flexibility to use the same tools in different products. Often operators create the artifacts themselves, but there was one case in which, based on one operator’s idea for an adaptation to an industrial machine, the factory initiated contact with the manufacturer in order to implement the change to the machine.

Implications for design. This category evidences that operators found the need to create bespoke tools that mediate their interactions with the products they are producing. An implication for the design of individual tools is that they should take into account this needs to personalization and adaptation to one’s own way of working. This category also hints at implications for organizations. It suggests that experienced workers will find ways of creating their own tools to suit their own personal needs in pursuit of achieving what for them is a job well done.

Discussion

With this study, we found several examples of spontaneous design in industrial units, which evidences that industrial shopfloors constitute fertile ground for spontaneous design. The examples we found were dispersed across all categories defined by Akrich, although we did not find categories that were clearly more prominent than others and we did not conclude that there were sectors which were clearly more prone than others to show examples of spontaneous design. We found examples of spontaneous design in all industrial settings, except in the industrial unit in the lighting sector—we had the indication from one of the workers that there were examples of spontaneous design, especially made by older workers in the industrial unit, but we could not see or document them. We also found examples of appropriation which we categorized as affordances and handmade replicas, and we noticed that these interventions hinted at human behavior and human values inside the industrial units.

The artifact analysis of spontaneous design, as a design and user research method, allowed us to identify flaws in existing equipment in industrial shopfloors, as well as opportunities for the design of more appropriate equipment, therefore confirming the usefulness of studying spontaneous design examples to inform practice. Several instances of machinery with superimposed button labels, safety warnings, and instructions showed that the design of machinery was not optimized for usability—this is the identification of design flaws. Examples of opportunities for design were those where spontaneous designs mediated or added to human-machine interaction, something that had also been reported by Fisher and Boticcello (2018), such as the case of mirrors used to look inside the machine while it is working, or the frequently observed need of naming equipment’s owners. This reduces the chance of equipment being lost and supports territoriality (Brown, 2009).

Beyond this, the exercise of affinity mapping of spontaneous design examples also allowed us to identify large themes, which, in turn, help us understand the extent to which industrial workers are willing to appropriate their surroundings, as well as to tap onto the underlying motivations to engage in this type of practice. These findings were summarized into five prominent purpose categories: organizing and displaying utensils and materials, providing information, protecting people and equipment, cleaning machinery, utensils and products, and improving the craft. All of the examples intend to improve a certain situation into a desired state (Simon, 1996), which directly benefits the worker (e.g., protection from hazards), but also benefits the employer (e.g., improving product quality). To do spontaneous design, workers tend to use whatever materials and utensils are around—this is similar to what Loschiavo dos Santos (2000) found in contexts deprived of resources. This was evident in metallurgy industrial units, where the majority of spontaneous design examples were built out of metal, ranging from step stools and dustpans to tennis tables. We also noted how the characteristics of operators’ spontaneous designs tend to align with universal design principles (Mace et al., 1991), such as flexibility in use, perceptible information, low physical effort, or size and space for approach and use.

Through spontaneous design workers improved their working conditions, protecting their bodies from dangerous movements or from dangerous machine interactions. Workers also engaged in spontaneous design to protect the equipment they work with so that it functions correctly and for a long time. Through spontaneous design operators found ways of improving their performance as workers of a certain trade. Workers created space for carrying their tasks more efficiently, created artefacts and processes to enable flexibility and created artefacts or processes to improve rigor in their actions. The creation of means to clean machinery and products, as well as the tailoring of machinery and utensils to improve production of a certain work order evidence that workers also engaged in spontaneous design to improve the quality of the products being manufactured in the shopfloor.

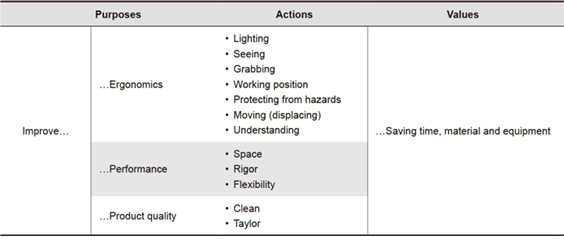

Therefore, we can derive a model of purposes, actions and values behind the spontaneous design examples we found in our study (Table 5). Our study, using a design research perspective and artifact analysis, corroborates previous research in the social sciences suggesting that that workers engage in spontaneous design to reach efficiency, effectiveness, satisfaction and safety (Cross, 2012; Juravich, 2017; Lynch, 2012; Narimoto et al., 2020; Pfeiffer, 2016). Spontaneous design is used to improve ergonomics, performance and product quality. Furthermore, we add to the existing literature by evidencing that these creations are not exempt from values. Analyzing these examples, we can see that workers engage in spontaneous design with the underlying values of resource efficiency: spontaneous design examples are created to save time, to reuse materials and to preserve equipment.

Table 5. Summary model of purposes, actions, and values behind spontaneous design in industrial shopfloors.

To the best of our knowledge, ours was the first study conducting a systematic inquiry into spontaneous design in industrial shopfloors. As a relevant output, we have also released our photographic database in open source so that other researchers can analyze it or increase it (Correia de Barros et al., 2023). Our analysis of spontaneous design examples revealed immediate opportunities for the design and redesign of industrial equipment. Furthermore, by revealing industrial workers’ values, current practices and how they created spontaneous design to improve human-machine interaction, our findings have a potential to add to current debates on the digitalization of industrial shopfloors and the implications thereof.

There are limitations in the study. Although we were able to build a rich dataset, our sample is made of industrial units where automation goes hand in hand with highly manual tasks, which might or might not be representative of most industrial sectors. The sample of workers engaging in spontaneous design that we were able to address is not large. We could not interact with many of the workers who did the spontaneous design, and so we lacked contextual information about the stories behind many artifacts. On the other hand, even without further contextual data, we were able to collect insights from several spontaneous design examples, which suggests that this method holds value even when there are no pre-conditions for participatory design, i.e., when workers are not available to take part in design research due to own will or force maijeure.

The fact that only 14 workers could be identified as creators of spontaneous design contrasts with the number of examples of spontaneous design found in our research. There was also, even in this small sample, an outlier of a participant who created many more spontaneous designs than the others. It is possible that some workers or some functions are more prone to the creation of spontaneous designs than others, but our study does not allow us to draw conclusions in this regard. In all visits we did, the employees doing the fieldwork tour with researchers were struck by the quantity of spontaneous design they had never noticed, as well as by the levels of creativity behind them. That we could not find most creators behind the spontaneous design examples we collected is another limitation of our work. However, one suggests that, despite the long-lasting practice of Kaizen (continuous improvement) in manufacturing, engagement in spontaneous design is not generally valued (with the exception of one industrial unit in our sample, which awarded prizes for certain types of such inventions), at least not to grant recognition. However, the sheer number of examples found, together with the purposes that they serve and their underlying values, lead us to conclude that engaging in spontaneous design is highly valuable for workers and employers. Future investment on providing visibility to industrial workers’ spontaneous design could help provide recognition and help dignify industrial operators’ work.

Future work could expand the analysis of spontaneous design by including other industrial sectors and other geographies, as well as compare engagement in spontaneous design between less automated and more automated industrial units. Since Akrich’s (1998) framework is based on form and function, it was easy to implement it by a team of design researchers. Analyzing the functional aspects of the spontaneous design examples facilitated the identification of purposes, and the analysis of configuration brought to our attention the techniques and materials that were employed by the workers. However, we also found the need to analyze other objects that did not fit the description of spontaneous design to address our study aim. Therefore, although we have used Akrich’s framework, future research could use different frameworks and compare findings.

Conclusion

We found that, within industrial shopfloors, there are several examples of spontaneous design. Our analysis revealed that workers engage in all types of appropriation described by Akrich (1998), the category of Extension being the most prominent one. This shows that workers find the need to intervene on the work equipment to add functions to it. We also found that spontaneous design in this context is motivated by a will to improve ergonomics, performance and product quality, following a certain set of values. We found that many spontaneous designers were unrecognized, but those who were tended to be older and more experienced workers.

From the analysis of spontaneous design examples, we were able to distill insights for design practice, therefore indicating that this type of artifact analysis might be useful for user research in design (research).

Acknowledgments

This work was supported by the Portuguese Foundation for Science and Technology (project reference 2022.01777.PTDC). The authors would like to thank all of the industrial units who kindly opened their doors to us, as well as all the workers in those units who shared their experiences and artifacts with us.

References

- Akrich, M. (1998). Les utilisateurs, acteurs de l’innovation [Users, actors of innovation]. Éducation Permanente, 134, 79-90.

- Angelo. (2003). Prisoners’ inventions. WhiteWall.

- Ardito, C., Buono, P., Caivano, D., Costabile, M. F., Lanzilotti, R., & Dittrich, Y. (2014). Human-centered design in industry: Lessons from the trenches. Computer, 47(12), 86-89. https://doi.org/10.1109/MC.2014.355

- Arkhipov, V. (2006). Home-made: Contemporary Russian folk artifacts. Fuel Pub.

- Bannon, L. J., & Bødker, S. (1989). Beyond the interface: Encountering artifacts in use. DAIMI Report Series, 18(288). https://doi.org/10.7146/dpb.v18i288.6666

- Botero, A., Kommonen, K., & Marttila, S. (2010). Expanding design space: Design-in-use activities and strategies. In Proceedings of the DRS international conference on design and complexity. Design Research Society.

- Boufleur, R. N. (2013). Fundamentos da gambiarra: A improvisação utilitária contemporânea e seu contexto socioeconômico [Foundations of gambiarra: Contemporary utilitarian improvisation and its socioeconomic context, Unpublished doctoral dissertation]. University of São Paulo.

- Brandes, U., Stich, S., & Wender, M. (2009). Design by use: The everyday metamorphosis of things. Birkäuser Verlag.

- Brown, G. (2009). Claiming a corner at work: Measuring employee territoriality in their workspaces. Journal of Environmental Psychology, 29(1), 44-52. https://doi.org/10.1016/j.jenvp.2008.05.004

- Cheon, E. (2023). Powerful futures: How a big tech company envisions humans and technologies in the workplace of the future. Proceedings of the ACM on Human-Computer Interaction, 7(CSCW2), Article 312. https://doi.org/10.1145/3610103

- Cheon, E., & Khovanskaya, V. (2024). Amazon Z to A: Speculative design to understand the future of labor-intensive workplaces. In Proceedings of the ACM conference on designing interactive systems (pp. 314-327). ACM. https://doi.org/10.1145/3643834.3661561

- Correia de Barros, A., & Duarte, C. (2009). Assistive devices: Stroke patients’ design. In Proceedings of the 17th ACM conference on creativity and cognition (pp. 79-86). ACM. https://doi.org/10.1145/1640233.1640248

- Correia de Barros, A., Duarte, C., & Cruz, J. B. (2010). ‘I made it myself’ – DIY in the design of assistive devices for stroke patients. In Proceedings of the 7th international conference on design & emotion. Illinois Institute of Technology.

- Correia de Barros, A., Magalhães, I., Correia, C., & Moutinho, R. (2024, May 17). Generating design briefs based on the analysis of workplace artifacts invented by industrial workers: Towards addressing gaps of context and scope in the study of spontaneous design. Paper presented at the conference of the Cumulus Association, Moholy-Nagy University of Art and Design Budapest, Budapest,

- Correia de Barros, A., Moutinho, R., Correia, C., Magalhães, I., & Couto da Silva, J. (2023). Dataset of spontaneous design examples from industrial shopfloors. Zenodo. https://doi.org/10.5281/zenodo.10182679

- Cross, J. (2012). Technological intimacy: Re-engaging with gender and technology in the global factory. Ethnography, 13(2), 119-143. https://doi.org/10.1177/1466138111410621

- De Bozzi, P., & Oroza, E. (2002). Objects reinventés: La création populaire à Cuba [Reinvented objects: Popular creation in Cuba]. Alternatives.

- Dix, A. (2007). Designing for appropriation. In Proceedings of the 21st British HCI group annual conference on people and computers (pp. 27-30). BCS Learning and Development. https://doi.org/10.14236/ewic/hci2007.53

- Dourish, P. (2003). The appropriation of interactive technologies: Some lessons from placeless documents. Computer Supported Cooperative Work, 12(4), 465-490. https://doi.org/10.1023/A:1026149119426

- Eglash, R. (2004). Appropriating technology. An introduction. In R. Eglash, J. L. Croissant, G. Di Chiro, & R. Fouché (Eds.), Appropriating technology: Vernacular science and social power (pp. vii-xxi). University of Minnesota Press.

- Fisher, T., & Botticello, J. (2018). Machine-made lace, the spaces of skilled practices and the paradoxes of contemporary craft production. Cultural Geographies, 25(1), 49-69. https://doi.org/10.1177/1474474016680106

- Govaerts, R., Tassignon, B., Ghillebert, J., Serrien, B., De Bock, S., Ampe, T., El Makrini, I., Vanderborght, B., Meeusen, R., & De Pauw, K. (2021). Prevalence and incidence of work-related musculoskeletal disorders in secondary industries of 21st century Europe: A systematic review and meta-analysis. BMC Musculoskeletal Disorders, 22(1), Article 751. https://doi.org/10.1186/s12891-021-04615-9

- Hirsch, T., Forlizzi, J., Hyder, E., Goetz, J., Stroback, J., & Kurtz, C. (2000). The ELDer project: Social and emotional factors in the design of eldercare technologies. In Proceedings of the conference on universal usability (pp. 72-79). ACM. https://doi.org/10.1145/355460.355476

- Jacobson, S., & Pirinen, A. (2007). Disabled persons as lead users in the domestic environment. In Proceedings of the conference on designing pleasurable products and interfaces (pp. 158-167). ACM. https://doi.org/10.1145/1314161.1314175

- Jencks, C., & Silver, N. (2013). Adhocism: The case for improvisation. The MIT Press.

- Juravich, T. (2017). Artifacts of workers’ knowledge: Finding worker skill in the closing and restructuring of a furniture manufacturer. Ethnography, 18(4), 493-514. https://doi.org/10.1177/1466138116687590

- Kohtala, C., Hyysalo, S., & Whalen, J. (2020). A taxonomy of users’ active design engagement in the 21st century. Design Studies, 67, 27-54. https://doi.org/10.1016/j.destud.2019.11.008

- Laschke, M., Braun, C., Neuhaus, R., & Hassenzahl, M. (2020). Meaningful technology at work–A reflective design case of improving radiologists’ wellbeing through medical technology. In Proceedings of the SIGCHI conference on human factors in computing systems (pp. 1-12). ACM. https://doi.org/10.1145/3313831.3376710

- Lévi-Strauss, C. (1966). The savage mind. The University of Chicago Press.

- Loschiavo dos Santos, M. C. (2000). Spontaneous design, informal recycling and everyday life in postindustrial metropolis [Lecture]. Retrieved from http://www.closchiavo.pro.br/site/pdfs/spontaneous_design.pdf

- Lynch, C. (2012). Retirement on the line: Age, work, and value in an American factory (Illustrated ed.). ILR Press.

- Mace, R. L., Hardie, G. J., & Place, J. P. (1991). Accessible environments: Toward universal design. The Center for Universal Design.

- Maiden, N., Zachos, K., Lockerbie, J., Camargo, K., & Hoddy, S. (2017). Establishing digital creativity support in non-creative work environments. In Proceedings of the conference on creativity and cognition (pp. 222-231). ACM. https://doi.org/10.1145/3059454.3059460

- Mayer, T. K. (2007). One-handed in a two-handed world (3rd ed.). Prince Gallison.

- Miller, D. (2009). The comfort of things. Polity.

- Mörike, F. (2022). Inverted hierarchies on the shop floor: The organizational layer of workarounds for collaboration in the metal industry. Computer Supported Cooperative Work, 31(1), 111-147. https://doi.org/10.1007/s10606-021-09415-2

- Myerson, J., Bichard, J.-A., & Erlich, A. (2010). New demographics new workspace: Office design for the changing workforce. Routledge.

- Narimoto, L. R., Costa Belussi, S. E. A., & Camarotto, J. A. (2020). Design-in-use applied to Brazilian agriculture: The case of citrus and sugarcane harvesting. Work, 65(3), 689-698. https://doi.org/10.3233/WOR-203101

- Nur, H., Altay, C., & Gizem, Ö. (2019). ‘Halletmek’: An inventory of everyday design and production. In Design revolutions: IASDR 2019 Conference Proceedings. Volume 1: Change, Voices, Open. Manchester Metropolitan University (pp. 610-627). IASDR. ISBN: ISBN 978-1-910029-59-6

- Oliveira, P., Zejnilovic, L., Canhão, H., & von Hippel, E. (2015). Innovation by patients with rare diseases and chronic needs. Orphanet Journal of Rare Diseases, 10, Article 41. https://doi.org/10.1186/s13023-015-0257-2

- Orr, J. E. (1996). Talking about machines: An ethnography of a modern job. Cornell University Press.

- Pfeiffer, S. (2016). Robots, industry 4.0 and humans, or why assembly work is more than routine work. Societies, 6(2), Article 16. https://doi.org/10.3390/soc6020016

- Pfeiffer, S. (2018). The `future of employment` on the shop floor: Why production jobs are less susceptible to computerization than assumed. International Journal for Research in Vocational Education and Training, 5(3), 208-225. https://doi.org/10.13152/IJRVET.5.3.4

- Rosenberg, C. (1968). Assistive devices for the handicapped. American Rehabilitation Foundation.

- Simon, H. A. (1996). The sciences of the artificial. The MIT Press.

- Spektor, F., Fox, S. E., Awumey, E., Riordan, C. A., Rho, H. J., Kulkarni, C., Martinez-Lopez, M., Stringam, B., Begleiter, B., & Forlizzi, J. (2023). Designing for wellbeing: Worker-generated ideas on adapting algorithmic management in the hospitality industry. In Proceedings of the conference on designing interactive systems (pp. 623-637). ACM. https://doi.org/10.1145/3563657.3596018

- Stein, J. A. (2021). Industrial craft as design knowledge: Hidden intermediaries of design and production. In J. A. Stein (Ed.), Industrial craft in Australia: Oral histories of creativity and survival (pp. 95-120). Springer. https://doi.org/10.1007/978-3-030-87243-4_4

- Storni, C. (2010). Multiple forms of appropriation in self-monitoring technology: Reflections on the role of evaluation in future self-care. International Journal of Human-Computer Interaction, 26(5), 537-561. https://doi.org/10.1080/10447311003720001

- Suri, J. F., & Ideo. (2005). Thoughtless acts?: Observations on intuitive design. Chronicle Books.

- Von Hippel, E. (1976). The dominant role of users in the scientific instrument innovation process. Research Policy, 5(3), 212-239. https://doi.org/10.1016/0048-7333(76)90028-7

- Wakkary, R., & Maestri, L. (2008). Aspects of everyday design: Resourcefulness, adaptation, and emergence. International Journal of Human-Computer Interaction, 24(5), 478-491. https://doi.org/10.1080/10447310802142276

- Zuboff, S. (1989). In the age of the smart machine: The future of work and power. Basic Books.

Appendix

Appendix I. Descriptions of photographs shown in Figure 5.

Appendix II. Descriptions of photographs shown in Figure 6.

Appendix III. Descriptions of photographs shown in Figure 7.

Appendix IV. Descriptions of photographs shown in Figure 8.