Exploring How Industrial Designers Can Contribute to Scientific Research

University of Cambridge, Cambridge, UK

This paper describes the initial findings of an empirical study exploring how industrial designers might be able to support scientists in their research activities. The paper compares and contrasts the findings of a literature review, a series of interviews with scientists and three case studies in which designers collaborated with scientific teams at a university. It reflects on the designers’ contribution to research and highlights potential barriers and enablers to collaboration. In addition to the expected contribution of designers to supporting commercialisation of technology, the research demonstrated the potential for industrial design to have an impact on research itself. When involved earlier in the scientific research process, designers can challenge the research direction and support scientists in demonstrating, communicating and exploring potential future applications.

Keywords – Collaboration, Industrial Design, Multidisciplinary, Science.

Relevance to Design Practice – This paper explores how industrial designers might be able to effectively support scientists in their research activities with a view to fostering effective collaboration.

Citation: Driver, A. J., Peralta, C, & Moultrie, J. (2011). Exploring how industrial designers can contribute to scientific research. International Journal of Design, 5(1), 17-28.

Received June 1, 2010; Accepted December 20, 2010; Published April 30, 2011.

Copyright: © 2011 Driver, Peralta, and Moultrie. Copyright for this article is retained by the authors, with first publication rights granted to the International Journal of Design. All journal content, except where otherwise noted, is licensed under a Creative Commons Attribution-NonCommercial-NoDerivs 2.5 License. By virtue of their appearance in this open-access journal, articles are free to use, with proper attribution, in educational and other non-commercial settings.

*Corresponding Author: ajd95@cam.ac.uk

Introduction

There is potential for industrial design to play an important role in the advancement of science and technology as highlighted by Lord Sainsbury in his 2007 Review of Science and Innovation. “Evidence suggests that the use of design helps scientists to develop commercial applications for their work while it is still at a research stage or at the outset of technology” (Sainsbury, 2007). Skilled designers provide a key link in ensuring that the needs of customers are central in the development of new technology and bring unique skills to complement the bias of technologists towards functionality (Kurvinen, 2005).

There is substantial evidence of the value of industrial design in the development of new technology in industry (e.g. Black & Baker, 1987; Gemser & Leenders, 2001; Hertenstein, Platt, & Brown, 2001; Kotler & Rath, 1984; Lorenz, 1994; Roy, 1999). These authors conclude that industrial designers can help to commercialise technology by becoming involved earlier in the development process. Surprisingly little academic work has been carried out exploring how industrial designers might be able to contribute to scientific research from which much technology originates. Existing studies in this area are anecdotal and lack first hand evidence of the factors influencing collaboration. This paper reports on the initial findings of an empirical study in which designers worked collaboratively with scientists at a university in supporting their research activities.

General Approach

This study consisted of three main phases:

- A review of existing literature related to collaboration between designers and scientists.

- A series of short interviews with scientists to gain a better understanding of their perceptions of design and designers, and their views on how designers might be able to contribute to their research.

- Three collaborative case study projects in which the research team offered design support to scientific teams from a variety of disciplines.

At each stage, the research team considered these questions:

- How can industrial designers contribute to scientific research?

- What factors may act as barriers or enablers to collaboration between designers and scientists?

We describe the detailed methods used for the interviews and case studies at the start of each relevant section. The paper compares the findings of each stage of the project with regard to these research questions before drawing conclusions and implications for further study. We sent a draft of the paper to participant scientists for feedback, incorporating their comments into the text.

Literature Review

Scientific Research

The literature review firstly establishes the scope of the study in the light of the nature of scientific research. ‘Science’ covers a wide range of disciplines and research activities, the contribution of industrial design to scientific research being likely to depend on the research context.

Scientific research can be said to encompass any activity employing scientific methods as illustrated by Pierce’s outline classification of science (Vehkavaara, 2001). Given industrial designers’ preference for the creation of products and systems, this study focuses on the physical and biological (e.g. physics, chemistry, and biology) and applied (e.g. engineering and medicine) sciences, although contributions to the social and formal sciences are considered.

Bauer describes the conventional definition of the scientific method as “systematic controlled observation or experiment, whose results lead to hypothesis, which are found valid or invalid through further work, leading to theories that are reliable because they were arrived at with open mindedness and continual critical scepticism” (Bauer, 1992, p. 19). This suggests an essentially linear, sequential process. Linear models have also been applied to scientific and technological development in the form of Applied Science Readiness Levels (ASRLs) and Technology Readiness Levels (TRLs), which were developed by NASA to manage their R&D programmes (Millis, 2005, p. 13; US DoD, 2002, pp. 204-205). The TRL model, for example, classifies technological development by nine stages ranging from “basic principles observed” to “actual system proven” and includes the stages ‘technology concept formulated’, ‘breadboard test in laboratory’ and ‘sub-system prototype demonstration in context’.

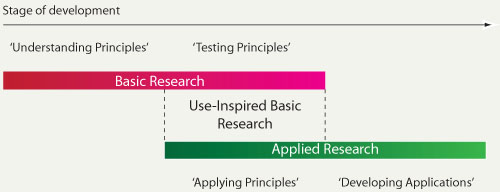

The most common, simple classification of research is to describe it as either “basic” or “applied”, the former being focused on improving understanding of fundamental principles, and the latter focused on considerations of use. Stokes (1997) suggests a third category of research motivated by both the pursuit of understanding principles and their application, which he called ‘use-inspired basic research’ (p. 73). Webster (1991) argues that distinctions between basic and applied science are becoming irrelevant in the context of interdisciplinary research.

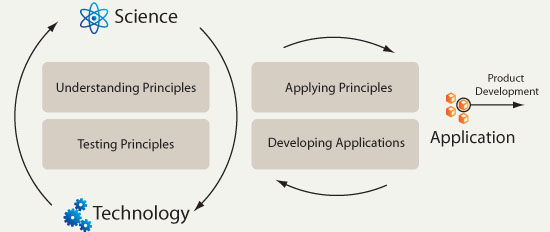

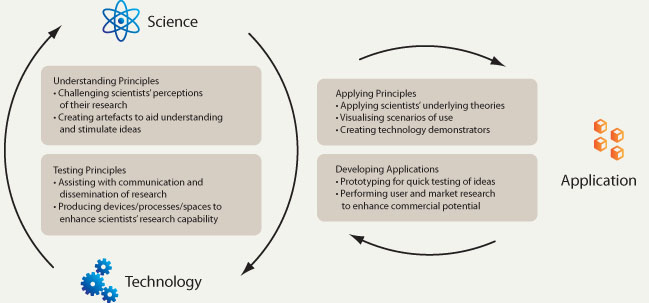

Based on these views, we developed a model of scientific research to position scientists’ work in terms of the stage of development and motivation. The model shown in figure 1 shares Stokes’s motivations for scientific research and anticipates definable stages of development similar to TRLs.

Figure 1. Model of scientific research (modified Stokes model 1997).

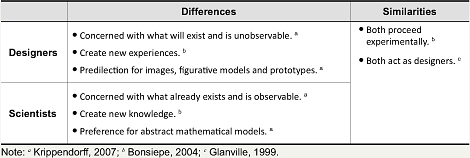

Collaboration between Designers and Scientists

In his review of literature related to the similarities and differences between designers and scientists, Peralta (2010) comments that design researchers have not sought to understand how these factors may affect collaborative work. Instead, they compare designers and scientists in relation to their “object of study and practice methods and outputs” (p. 1645). For example, Krippendorff (2007) suggests that scientists are concerned with what already exists and is observable and designers are preoccupied with what will exist and is unobservable. He adds that scientists search for generalisations and make use of abstract mathematical models, but designers pursue plausible “causes of action” that explain their predilection for “images, figurative models and prototypes” (p. 73). Bonsiepe (2007, p. 28) writes that scientists produce “new knowledge” and designers create “new experiences” for people, although he notes that both can proceed experimentally. Glanville (1999, p. 88) comments that research is “a design activity” in which the researcher “designs experiments” and “acts as a designer”. Table 1 summarises these opinions.

Table 1. Differences and similarities between designers and scientists.

Chris Rust has produced some of the most relevant literature on the subject of collaboration between designers and scientists. In one paper, Rust (2004) proposes that designers’ ability to “embody ideas and knowledge in artefacts” can allow them to contribute to research by stimulating others to develop and evaluate new ideas. He illustrates his point with several examples in which he claims that the designers’ contributions to research included:

- Developing prototype medical devices for quick testing of ideas.

- Challenging scientist’s perception of their data by representing it in new ways.

- Applying scientists’ underlying theories to a piece of multimedia design for Alzheimer’s sufferers.

- Producing a model arm to help scientists understand the mechanics of the elbow joint. This contributed to research by “complementing relatively unreliable quantitative data” and stimulating ideas for replacement joints and surgical simulators.

Rust suggests that there is a risk that collaborators will not recognise the contributions that designers can make to scientific research, arguing that it may be necessary for designers to “be subversive, to invest time and effort in finding opportunities to demonstrate what can be achieved before partners start to understand the possibilities” (p. 85). Additionally, he suggests that designers seek open-minded collaborators. Another potential barrier to collaboration is the designer’s self image:

If designers imagine that research and the creation of knowledge is a matter for others, then they may find themselves in a subsidiary role (or no role at all) in research. To overcome this takes not only self confidence, but also a proper appreciation of, and respect for, the knowledge and methods of scientists. (Rust, 2004, p. 84-85)

In a 2007 paper, Rust provides further examples of collaboration, including the production of a film to communicate the principles of “molecular actions in nanotechnology” (p. 74) to the general public. He points out the difficulties in communication experienced between the designers and scientists because they “lacked any shared formal language” (p. 74). He reiterates that it may be difficult to define the contribution made by designers to research since it can be indirect, for example, by stimulating insights in others that lead to scientific advancement.

Although Rust offers an interesting perspective on interdisciplinary collaboration, he does not present empirical evidence to support his claims. It seems that his conclusions have been drawn from discussions with designers and not from the scientists involved. Furthermore, recognising the wide variety of scientific activity from basic research through to application, he does not comment on how the contribution of designers may vary with the context of the research.

The UK Design Council has run a pilot ‘mentoring’ program aimed at bringing design expertise into university research. Initially, the mentoring sought to support the commercialisation of technology through industrial design; it has since moved increasingly towards providing strategic advice. In 2009, the pilot program teamed Maddison Design with Isis, a technology transfer office at Oxford University, for a pilot scheme entitled “Design for Technology Transfer” (Design Council, 2009). Maddison Design provided strategic design mentoring for three scientific research teams working on a variety of technologies. They created scenarios of use for two of the technologies to help communicate their potential to investors, which resulted in them gaining significant funding. These projects illustrated the perceived importance of this area of study, but there is little available material documenting the collaborations and the participants’ thoughts and opinions.

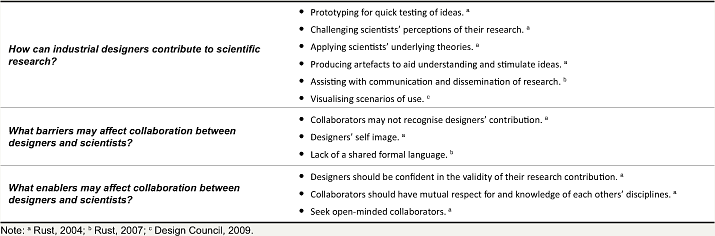

Literature Review Summary

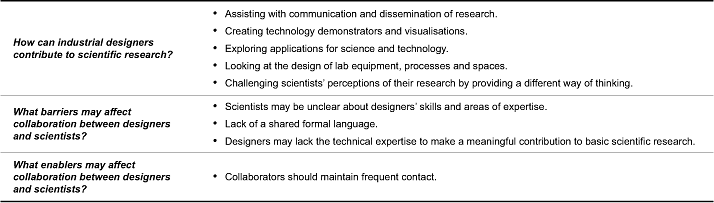

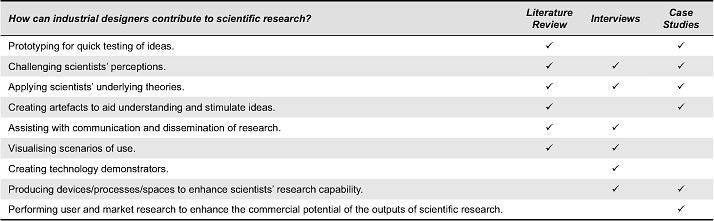

Table 2 summarises the initial findings of the literature review with regard the research questions.

Table 2. Summary of literature review findings.

Interviews with Scientists

Before starting any formal case studies, the research team first interviewed scientists from a variety of disciplines to explore some of the issues raised in the literature review. The objectives of the interviews were:

- To explore the scientists’ perception of the status of their research.

- To gauge the scientists’ initial perceptions of design and designers.

- To understand the scientists’ views on how designers might support their research activities.

Approach

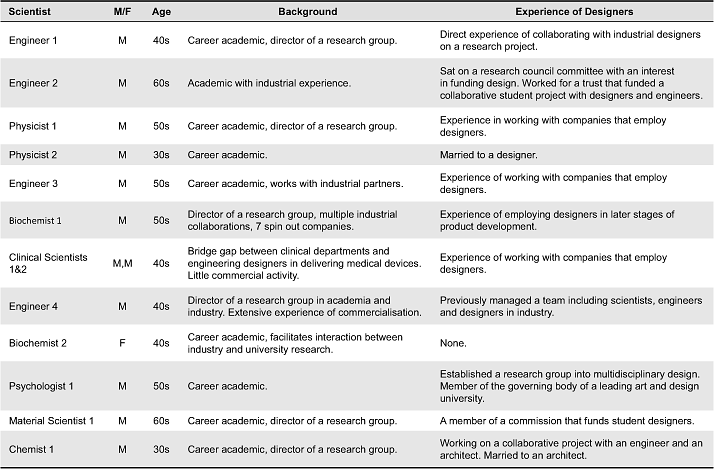

We selected interviewees following meetings with the head of research at the university’s engineering department and representatives from the university research support service, the aim being to represent varied scientific disciplines and backgrounds as detailed in table 3.

Table 3. Description of interview participants.

We created a semi-structured interview in three parts to tackle each of the above objectives:

- We firstly asked the scientists to describe their personal area of research and their individual research activities. We asked the scientists to try to position their research on the map developed in the literature review (figure 1) to indicate their motivation, and to define any specific stages of their research process.

- We then asked them to explain their understanding of the word ‘design’ and to describe any experience they had of working with designers. We asked those with prior experience to comment on how they overcame any difficulties in the collaboration. We then invited the interviewees to list the characteristics of a designer under the headings Skills, Knowledge, Ways of Thinking and Role. We adapted these categories from the Scottish Credit and Qualification Framework to reflect what is expected of a professional designer by industry (SCQF, 2007).

- Finally, we encouraged the scientists to identify potential opportunities for the designer they had described in the second part of the interview to support them in their scientific research activities. The first interviewees struggled to make suggestions here. After the sixth interview, we followed this question with a list of potential design contributions to stimulate further debate as shown below. This list drew on recommendations of the Design Council’s pilot scheme in which design consultancies worked with scientific researchers (Design Council, 2006). It also contains suggestions made by the first six interviewees, such as the design of lab spaces and equipment.

- Application Exploration

- User/Market Research

- Concept Design

- Materials/Manufacturing Processes

- Engineering Design

- Prototyping

- 3D Visualisation

- 2D Communications

- User Interface Design

- Lab Space/Equipment Design

- Stimulate Interest/Excite

- Challenge Established Views

We recorded the interviews and transcribed sections to enable later coding.

Results

Scientists’ Perception of the Status of Their Own Research

Nearly all of the scientists described their research activities as including elements of both basic and applied research. This was because the scientists were often working on multiple projects with research teams from other universities. This supports Webster’s assertion that the boundary between basic and applied research has become blurred (Webster, 1991). It emerged that much of their work is also inherently iterative, with both application and the search for underlying principles occurring concurrently. This suggests that linear development models such as TRLs do not easily apply.

Following the interviews, the research team constructed a new model that more accurately reflected research being conducted at the university. Figure 2 indicates how basic and applied research can give rise to applications and how the development of applications can generate new scientific and technological research.

Figure 2. Model of scientific research post interviews.

Scientists’ Initial Perceptions of Design and Designers

When asked to describe what they understood by the word ‘design’, many of the scientists related it to their own activities, such as engineering design, experimental design and survey design. Some did not make clear distinctions between these and non scientific disciplines such as industrial and product design, thinking rather of design in its broadest sense. Some of the scientists’ initial perceptions of designers were as superficial stylists.

Product design is a bit more airy fairy really isn’t it? – it tends to be the fashion stylistic sort of approach...an industrial designer is just an engineer in my view [Engineer 1].

We rough out the ideas and it goes to a professional [designer] who tarts it up [Biochemist 1].

Some of the scientists had experience of collaborating with designers on the development of commercial applications of science and technology. They cited communication problems as the most common obstacle to collaboration. These issues were overcome by maintaining frequent contact with collaborators in the form of brainstorming sessions, meetings and workshops:

I need a little bit of fill-in on some technical terms that might be utilised by him and in my case he would definitely need fill-in on the technical terms because he’s not a chemist [Chemist 1].

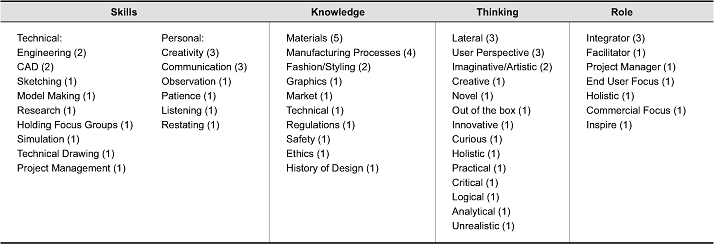

When asked to list the characteristics of a designer, the scientists produced a very broad range of answers. Some confusion arose as to the type of designer they were being asked to describe; some listed their own characteristics in their capacity as a designer, others spoke about industrial design, graphic design or designers in a broader sense. Table 4 presents a selection of the most common and interesting answers. The numbers in brackets represent the number of scientists who mentioned each point.

Table 4. Characteristics of designers according to scientists.

These results support Glanville’s assertion that scientists often act as designers (Glanville, 1999). Other than materials and manufacturing knowledge, the lack of any wider consensus on the characteristics of professional designers suggests an overall lack of awareness of designers’ skills and areas of expertise.

Scientists’ Views on How Designers Might Support Their Research Activities

The scientists were generally skeptical about the potential for industrial designers to contribute to early stages of scientific research:

I find it difficult to believe that they [designers] could contribute much round here [Understanding principles] because you’d have to have a really detailed knowledge of the detailed science...You’re better coming in somewhere around here [Developing applications] [Biochemist 1].

A minority of the scientists didn’t rule out a possible contribution by designers to scientific research:

How do you access the unknown unknowns, yes? The scientist isn’t going to do it because it’s unknown by definition yes? Anyone with different viewpoint...different ways of thinking about things, approaching problems can perhaps provide a route into those unknown unknowns. Every bit of science is suffering from this because every real issue in science at the moment is complex [Physicist 1].

When presented with the list of possible design contributions to scientific research, the scientists most frequently selected assistance with 2D communications, including funding applications, conference posters and outreach material:

If someone can help me to see from the outside what the research looks like...that will help me putting my work across [Physicist 2].

This was followed by 3D visualisation, application exploration and the design of lab spaces and equipment. Despite having identified that designers know about materials and manufacturing processes, the scientists did not indicate that their research would benefit from support in these areas. The same was true of other traditional industrial design tasks such as user/market research and concept design. The scientists suggested that designers might be able to help with the creation of more sophisticated technology demonstrators to help with funding proposals and public outreach. Interestingly, some scientists mentioned the design of lab equipment and processes:

I think that might be interesting if designers could spot ways of improving that [scientific] process...by perhaps looking at the laboratory equipment, the methods of handling or moving or managing or conveying substances, the methods of testing...it could be design of the space, design of laboratory, design of the bench...that’s where I would say the contribution could come in [Engineer 1].

Interview Summary

The scientists perceived a greater possible impact on applied rather than basic research through the engagement of professional design skills. This result suggests that design engagement could be suitable for many scientists as their work includes both basic and applied research. The opinions of the scientists are summarised in Table 5.

Table 5. Summary of interview findings.

Case Studies

In the final stage of the study, the research team of two designers set up collaborative projects with scientists to gain first hand evidence of the potential contributions of industrial design to scientific research.

Approach

We chose three case study projects from a selection offered by the university technology transfer office to represent a variety of scientific disciplines and research requirements. All of the scientific teams involved were to some extent focused on the commercial exploitation of their research outputs. The chosen projects were:

- Design of an oxygen mask with an anesthetist.

- Development of a fluid handling system for a common lab test with two biological chemists.

- Manufacturing a prototype for a fashion application of multistable materials with a structural engineer.

The projects we rejected were either not significantly different from the first three, or provided limited opportunity for design engagement.

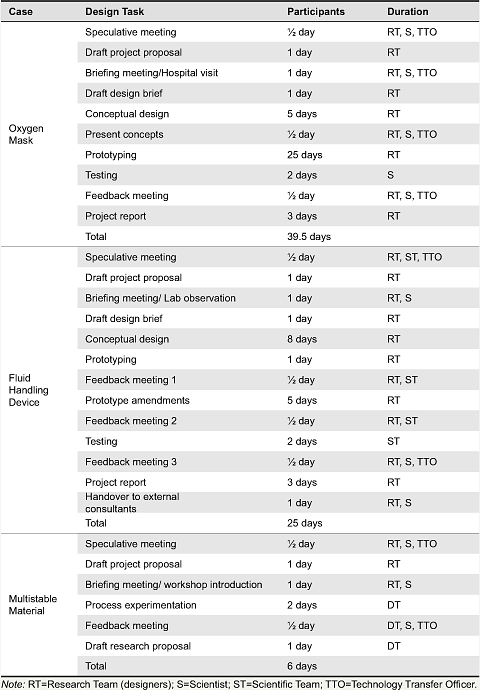

Table 6 summarises the design tasks carried out for each case study. This is followed by detailed descriptions for each of the case studies. Where possible, we recorded meetings with the participant scientists, as we did with semi-structured interviews before and after the projects. We recorded the progress of the cases using a combination of notes, sketches, documents, photographs, and video. At the end of each case study, a report was written to record the results of the project, as well as the thoughts of both the research team and the scientific team on the nature of the collaboration. The research team’s views were sent to the scientists so they could comment on their interpretation of events.

Table 6. Summary of design tasks for each case study.

Results

Oxygen Mask

An anesthetist had identified a need for a facemask providing a near perfect seal with the patient’s face. Existing masks did not always provide a sufficiently good seal. Using materials he found at home, the scientist made a series of prototypes based on a sealing principle he had devised. He performed tests on himself using the mask, which gave close to 100% sealing. He approached the university technology transfer office with a desire to involve materials and manufacturing expertise prior to commercialisation. They suggested he would need the help of a designer to create another prototype.

At the initial meeting with the research team, the scientist explained that the next prototype should be designed to be tested on users and be suitable for presentation to potential manufacturers. The research team felt that although the scientist’s prototype performed well, it didn’t take into account the many human factors related to such a product. Specifically, they felt it had a threatening visual appearance, was uncomfortable and unsafe. The research team suggested that they initially focus on developing a mask for user testing. They also indicated that they should observe clinical and research use of the device and similar products in a hospital environment. The decision was taken not to enter into a formal IP (intellectual property) agreement with the scientist as it was felt this might form a barrier to collaboration.

There followed an observation day in which the research team gained sufficient knowledge to assemble a detailed design brief. Once this has been signed off by the scientist, design work began. The research team brainstormed several concepts, then produced a CAD rendering of their chosen design. This, along with development sketches and models, were presented to the scientist at a review meeting. The research team suggested an alternative physical construction of the mask based on the same sealing principle. The scientist was skeptical about this decision, but agreed to a prototype being constructed to test the idea.

The research team manufactured a prototype from medically approved materials and presented this to the scientist for testing. Despite achieving good results on a healthy volunteer, the research team’s prototype was found not to perform as well as the scientist’s prototype during a cadaver study. However, the new prototype did reveal aspects of the sealing mechanism not previously appreciated with the scientist’s prototype. The new prototype was also a great improvement in terms of appearance, comfort, ease of use and safety. The research team subsequently created a further prototype that was a hybrid of the two designs.

Figure 3. The anesthetist briefs the research team.

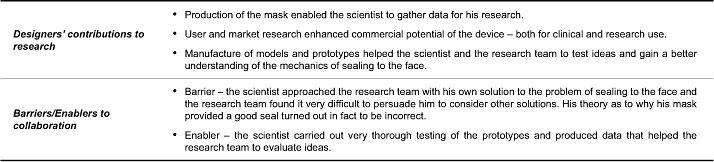

Table 7. Findings of oxygen mask project.

Fluid Handling Device

Two biological chemists had an idea for a fluid handling device that could significantly reduce the time taken to perform a very common laboratory test called an immuno assay. The scientists had been able to prove the fluid handling principle, but had not created a device to compare their concept with competing technologies. Thinking the concept had commercial potential, they approached the university technology transfer office to ask about patent protection and commercialisation. They recognised that they would require test data to support a funding application to develop the idea. The technology transfer office suggested that the research team assist in the creation of a working prototype.

At an initial meeting, the scientists were able to demonstrate the fluid handling principle using components from the laboratory, but weren’t able to perform a time comparison with other devices. It quickly became apparent that the technical terminology being used by the scientists was preventing the research team from understanding the physical processes involved. They subsequently asked if they could observe and film a typical immuno assay. The research team then created a design brief that included a visualisation of the immuno assay process and a description of issues of use that arose during the observation day, including modularity, labelling and human error caused by fatigue, boredom or stress. Once again, no formal IP agreement was entered into.

The research team created a series of sketch models using rapid prototyping techniques that could quickly be tested by the scientific team. Both teams immediately adopted a very interactive approach, with informal review meetings being held frequently. These acted as mini brainstorming sessions, with design decisions being made by consensus. Eventually, the research team produced a working prototype that allowed the scientists to perform a comparison with existing laboratory equipment.

The data from this experiment was used to support a funding proposal for £150k to develop the idea further, including a £25k provision for marketing and design. The scientific team was awarded the funding and sought out a professional design consultancy to provide assistance with the detailed design. The research team met with the external design consultants to hand over the project.

Figure 4. The designer performs an immuno assay during the observation day.

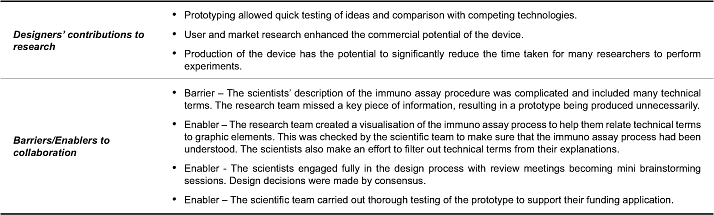

Table 8. Findings of fluid handling device project.

Multistable Material

A structural engineer developed a forming process to give sheet metal multistable properties. Thinking multistable materials would have commercial potential, he approached the technology transfer office to protect the forming process and commissioned market research to identify applications for the technology. The market research identified several applications, most of which required further developments in other areas of science. The scientist received commercial interest from a designer for a fashion application, but his material samples failed to generate enough interest to initiate a project. The technology transfer office suggested that designers become involved with the project to see if they could assist with commercialisation of the technology.

At the initial meeting, it became apparent that the scientist wanted to find a quick route to market to raise the profile of multistable materials since his real interests lay in conducting further research. All agreed that the fashion application provided a good opportunity to quickly produce something with a clear route to market, but that work would have to be done to miniaturise the forming process and experiment with other materials. The scientist promised to provide lab space with forming equipment and a supply of the material he was currently using. The research team suggested that they look into other applications of the technology. They were particularly excited by the possibility of using another forming process that the scientist had experimented with.

A design brief was created and the designers took to the lab to start working with the equipment and materials. It quickly became apparent that the forming process was more a craft than a precision procedure and that achieving multistable properties at smaller scales and with different materials would require the development of new forming equipment. In addition, the alternative forming process—which the designers felt showed more promise for the chosen application—was not well understood. It would require further theoretical work to be carried out before it could be applied.

The research team felt that the task they had agreed to perform would be better suited to a manufacturing engineer; the better use of their skills being in the development of the alternative forming process. They subsequently put together a proposal for a piece of theoretical work in which the research team would offer manufacturing support by producing test samples. The scientist explained that this would require specialist research that he did not have the resources for, although he saw promise in the proposal.

Figure 5. The scientist demonstrates the forming process to the research team.

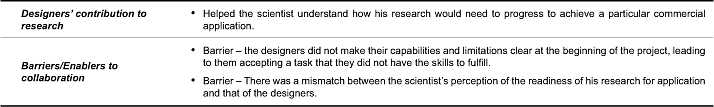

Table 9. Findings of multistable material project.

Results

Table 10 compares the findings of the literature review, interviews and case studies regarding the potential contributions of industrial designers to scientific research. The initial focus in each of the case studies was on the exploitation of technology and the development of applications. This was reflected in the tasks performed by the designers such as application exploration, user and market research and prototyping. Despite this commercial focus, the process of conceiving applications indirectly influenced research by raising further questions. For example, during the multistable material project, the designers suggested that the scientist focus on developing a different forming process that challenged his perception of how his research should progress. Also, by manufacturing prototype masks, the designers helped the scientist to understand that the mechanics of sealing to the face were more complex than he had first thought.

Table 10. Comparison of design contributions to scientific research.

The scientists participating in the interviews were more focused on research and wondered how a designer might support their everyday research activities. Hence, the suggested design contributions included assistance with communication, visualisation and demonstration. The case studies did not provide significant insight into these contributions.

The contributions identified during this study can be broadly separated into those with direct influence on the application of research outputs and those with an indirect influence in supporting research activity generally. Figure 6 illustrates this, showing the position of the contributions within the model of scientific research.

Figure 6. Potential contribution of industrial design to scientific research.

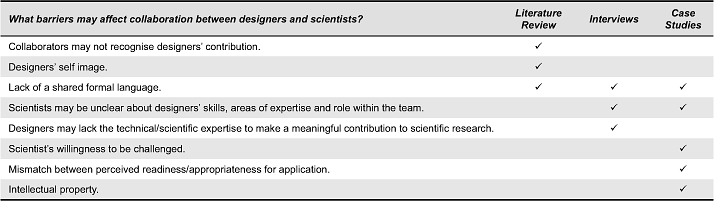

Table 11 compares the findings of the three phases of the study regarding potential barriers to collaboration between designers and scientists. The case studies did not provide insight into whether some of the issues raised in the literature review and interviews would be barriers to collaboration, for example, a lack of technical or scientific expertise. Again, this was due to the strong initial commercial focus of the case study projects, which clearly defined the research team’s contribution and meant they were not asked to tackle an issue directly related to the scientists’ research.

Table 11. Comparison of barriers to collaboration between designers and scientists.

The case studies highlighted that there is a risk that scientists might not be willing to be challenged on technical issues, suggesting a possible mismatch between their perception of the readiness/appropriateness of a technology for application and that of designers. The scientists highlighted intellectual property as an important issue. They understandably took a cautious approach to sharing it with third parties, especially if they were unsure about the designers’ involvement. However, it was broadly agreed that in the event that designers made a novel contribution to research or the outputs of research, they would be recognised with a formal IP agreement. The projects in the study were experimental in nature so no such agreements were entered into initially, although it became clear that co-invention was a distinct possibility in both the mask and fluid handling device projects.

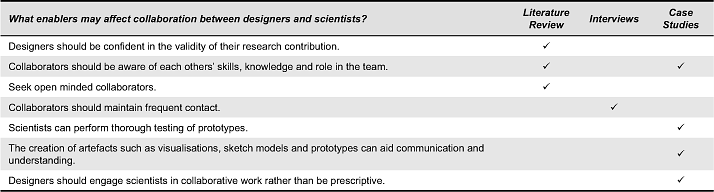

Table 12 compares the findings of the three phases of the study regarding potential enablers to collaboration between designers and scientists. The findings of the case studies supported the assertion from the literature review that collaborators need to appreciate the skills, knowledge and role of team members from other disciplines. The literature review also highlighted how artefacts can be used to stimulate ideas, but it did not specifically point out their usefulness in overcoming communication issues arising from a lack of shared formal language. This was achieved by creating simple visual representations of objects and processes, including key technical terms and symbols.

Table 12. Comparison of enablers to collaboration between designers and scientists.

The case studies demonstrated that scientists are able to carry out rigorous testing of product concepts, providing the designers and investors with valuable test data. The success of the fluid handling device case was largely due to the scientists’ willingness to interact with the designers and engage in the design process. However, the study did not provide insight into how to manage scientists’ perception of the readiness or appropriateness of their technology for application, the case studies suggesting this may lead to wasted time or missed opportunities.

Conclusions

The paper has shown that the results of the case studies were heavily influenced by the decision to identify case study partners through the university technology transfer office. This approach was taken as it was felt that it would initially be easier to convince scientific teams to participate in the study if they were focused on commercialising the results of their research. The results of the interviews supported this, suggesting that scientists generally saw designers playing a role later in the development of technology, specifically in applying technology that had already been developed.

As such, the participant scientists viewed the research team as providing a design service and the relationships between the designers and the scientists were very similar to those of designers and clients in industrial settings. However, unlike industry, the scientists’ primary concern is the advancement of understanding, not commercial success. Although the scientists perceived their work to be close to commercialisation, in reality this was not the case. For example, the scientist working on multistable materials had only been able to achieve multistable properties in small samples of a particular material using a forming process that was not well suited to mass production.

In attempting to commercialise technology, new questions arose that had the potential to feedback into basic research and contribute to understanding. For example, the designers assessed the commercial potential of the multistable material to be much greater if a different forming process and different materials were used. The scientist stated that more theoretical work would need to be carried out to address these issues. At the time of writing, the research team is negotiating the terms of a collaborative project to support this. Similarly, the insights into the principles of sealing an oxygen mask to the face gleaned during that study had the potential to form the basis of new research. At the time of writing, the research team and scientist are putting together a paper on the development of the mask for a medical journal.

We have therefore seen that designers can act as research catalysts by considering the early application of technology and focusing research on overcoming practical hurdles. Designers can also stimulate the creation of new knowledge by producing artifacts to test ideas and aid understanding. This challenges the conventional perception of designers as service providers. It suggests a role for designers in scientific research as co-researchers with a background in design. The intention for further work is that the designers present themselves in this new role, so that their relationship with scientists is different from the start of the project.

The next phase of the study will also address gaps in the research highlighted in this paper. Specifically, the research team will aim to engage with scientists working on early stage scientific research with less emphasis on commercialisation. This should address the potential design contributions raised during the interviews and in the literature review, including:

- Assisting with communication and dissemination of research.

- Exploring applications for new technologies.

- Visualising scenarios of use.

- Creating technology demonstrators.

- Challenging scientists’ perceptions of their research.

In addition, we also hope that collaboration in early stage science may reveal new and unexpected contributions.

The next phase of the study will also aim to address whether some of the potential barriers highlighted by the first phase of the study will indeed become issues in practice. This includes intellectual property, the designer’s lack of technical and scientific knowledge and whether or not scientists can recognise designers’ contributions if they are not explicit. Finally, it will be necessary to explore strategies for overcoming any issues that arise, including how to manage a mismatch in perceived readiness of a technology for application between designers and scientists.

To ensure that the case study partners for the next phase are less focused on commercialisation, they will be identified independently of the university technology transfer office. It will be necessary for the research team to present evidence of the contributions they have made to research in the first three case studies to persuade scientific teams to participate. Rust (2004) suggests that it may be necessary for designers to invest time and effort in building relationships with scientific teams and in finding opportunities to demonstrate what can be achieved through collaboration.

In the long term, this study hopes to develop strategies for facilitating work between industrial designers and scientists. This may include the development of a guide book to help scientists select and work with designers to enhance their research and its outputs. This may influence the way that research proposals and funding applications are made and the configuration of scientific research teams. The study may also influence scientists’ and designers’ perceptions of each other, potentially fostering collaboration.

Acknowledgements

We would like to thank the scientific teams and individuals who participated in the interviews and case studies, as well as Cambridge Enterprise who assisted in the identification of case study partners. We would also like to thank the Engineering and Physical Sciences Research Council, which funded the research.

References

- Bauer, H. H. (1992). Scientific literacy and the myth of scientific method. Urbana, IL: University of Illinois Press.

- Black, C. D., & Baker, M. J. (1987). Success through design. Design Studies, 8(4), 207-216.

- Bonsiepe, G. (2007). The uneasy relationship between design and design research. In R. Michel (Ed.). Design research now: Essays and selected projects (pp. 25-39). Basel, Switzerland: Birkhäuser.

- Design Council. (2006). Submission by the Design Council to the Lambert Review of business-university collaboration. London: Design Council.

- Design Council. (2009). Innovate for universities. Retrieved May 12, 2010, from http://www.designcouncil.org.uk/our-work/Support/Innovate-for-Universities/Case-studies/

- Gemser, G., & Leenders, M. (2001). How integrating industrial design into the product development process impacts on company performance. Journal of Product Innovation Management, 18(1), 28-38.

- Glanville, R. (1999). Researching design and designing research. Design Issues, 15(2), 80-91.

- Hertenstein, J. H., Platt, M. B., & Brown, D. R. (2001). Valuing design: Enhancing corporate performance through design effectiveness. Design Management Journal, 12(3), 10-19.

- Kotler, P., & Rath, A. (1984). Design: A powerful but neglected strategic tool. Journal of Business Strategy, 5(2), 16-21.

- Krippendorff, K. (2007). Design research, an oxymoron? In R. Michel (Ed.), Design research now: Essays and selected projects (pp. 67-80). Basel, Switzerland: Birkhäuser.

- Kurvinen, E. (2005). How industrial design interacts with technology: A case study on the design of a stone crusher. Journal of Engineering Design, 16(4), 373-383.

- Lorenz, C. (1994). Harnessing design as a strategic resource. Long Range Planning, 27(5), 73-84.

- Millis, M. G. (2005). Assessing potential propulsion breakthroughs. Annals of the New York Academy of Sciences, 1065, 441-461.

- Peralta, C., & Moultie, J. (2010). Collaboration between designers and scientists in the context of scientific research: A literature review. In D. Marjanovic, M. Storga, N. Pavovic, & N. Bojcetic (Eds.), Proceedings of the 11th International Design Conference (pp. 1643-1652). Glasgow, UK: The Design Society.

- Roy, R. (1999). The long term benefits of investing in new product development by SMEs. New Product Development & Innovation Management, 1(4), 281-295.

- Rust, C. (2004). Design enquiry: Tacit knowledge and invention in science. Design Issues, 20(4), 76-85.

- Rust, C. (2007). Unstated contributions: How artistic inquiry can inform interdisciplinary research. International Journal of Design, 1(3), 69-76.

- Sainsbury, D. (2007). The race to the top: A review of government’s science and innovation policies. London: HM Treasury.

- Scottish Credit and Qualifications Framework. (2010). SCQF level descriptors booklet. Retreived May 12, 2010, from http://www.scqf.org.uk/nmsruntime/saveasdialog.aspx?lID=623&sID=119

- Stokes, D. E. (1997). Pasteur’s quadrant: Basic science and technological innovation. Washington, DC: Brookings Institution Press.

- US Department of Defense. (2002). DoD 5000.2-R, mandatory procedures for major defense acquisition programs (MDAPS) and major automated information systems (MAIS) acquisition programs. Washington, DC: US Department of Defense.

- Vehkavaara, T. (2001). The outline of Peirce’s classification of sciences (1902-1911). Retrieved May 12, 2010, from http://www.uta.fi/~attove/peirce_systems3.PDF

- Webster, A. (1991). Science, technology and society: New directions. Hong Kong: Macmillan.