A Framework and Representation for Universal Product Design

Texas A&M University, College Station, Texas, USA

This paper presents a product analysis framework for improving research and practice in universal design—a term commonly used to describe goods and services that are usable both by persons with a disability and by typical users. Seventeen percent of the U.S. population has some form of a disability. Nevertheless, many companies are unfamiliar with approaches to achieving universal design. A key element of the framework presented here is the combination of activity diagrams and functional models. The framework is applied in the analysis of 20 pairs of products that satisfy a common high-level need, but are different in that one of the products is intended for fully able users while the other is intended for persons with a disability or with reduced functioning. Discoveries based on the analysis include categorizing the differences between typical and universal products as functional, morphological, or parametric. Additionally, it appears that simple products can be made more accessible through parametric changes, whereas more complex products require functional additions and changes.

Keywords – Universal Design, Accessible Design, Functional Modeling, Activity Diagrams.

Relevance to Design Practice – There is economic and ethical motivation to design products usable by persons with a disability. However, there are limited formalisms for facilitating universal design early in the design process. This paper presents a new formal representational framework for designing universal products and uses it to compare universal products and typical products.

Citation: McAdams, D. A., & Kostovich, V. (2011). A framework and representation for universal product design. International Journal of Design, 5(1), 29-42.

Received April 27, 2009; Accepted September 22, 2010; Published April 30, 2011.

Copyright: © 2011 McAdams and Kostovich. Copyright for this article is retained by the authors, with first publication rights granted to the International Journal of Design. All journal content, except where otherwise noted, is licensed under a Creative Commons Attribution-NonCommercial-NoDerivs 2.5 License. By virtue of their appearance in this open-access journal, articles are free to use, with proper attribution, in educational and other non-commercial settings.

*Corresponding Author: dmcadams@tamu.edu

Introduction

Seventeen percent of the U.S. population has some form of a disability (Erickson & Lee, 2003). Numbers are similar worldwide. Disability can have a negative impact on the work environment of individuals as well as on their general participation in the workforce. The unemployment rate for people with disabilities is 2 to 3 times higher and their labor participation rate is approximately 3.5 times lower than for fully able persons (Erickson & Lee, 2003). As life expectancy rises, a greater percentage of the population will have some form of disability, as the probability of people developing a disability increases with age.

As the population of people with disabilities grows, so does the ethical and economic pressure to provide that population with products that provide services and value. Nevertheless, many companies are unfamiliar with approaches to applying Universal Design (UD)--a term commonly used to describe goods and services that are usable both by persons with a disability and by typical users. One of the authors of this article had a recent conversation with a research engineer from a large consumer electronics manufacturing firm in which he asked: “What is your biggest design challenge?” The response was simple: “Universal design. How do you do it?”

A study in the U.K. of 87 design, manufacturing, and retail sector companies revealed several barriers to developing UD, or inclusive design—the term typically used in the United Kingdom rather than UD (Goodman, Dong, & Langdon, 2006). When asked why a designer, or company, was not involved in inclusive design, being “not aware” was the most frequent response. Furthermore, for those “not aware,” the most popular reason given was a lack of knowledge and tools. For those participants who were “extremely aware” of the concept of inclusive design, their most common reason for not being involved in it was thinking that inclusive design is too hard to implement.

In spite of the barriers to implementing UD, successful examples do exist. Two examples of successful companies that have implemented UD concepts are OXO and Toyota. Initially, OXO designed their Good Grip product-line as a line of kitchen tools with comfortable grips easily accessible to arthritic customers (Cagan & Vogel, 2002). In subsequent years, the market segment shifted to younger users interested in cooking with ergonomically friendly peelers, bottle openers and other cooking utensils. As a result, the OXO Good Grips products are an oft-cited example of a UD product success. An example of a vegetable peeler from the Good Grips line is shown in Figure 1.

Figure 1. An example of commercially successful Universal Design: the OXO Good Grip serrated vegetable peeler.

The Universal Design Showcase in Japan highlights UD concepts (Toyota, 2010). Figure 2 shows an example of a UD concept for sedans that was recently on display at the Japan exhibition. In this case, the chairs, knob placement, and trunk configurations are all designed as universal stock items rather than after-market add-ons. For example, the Toyota Crown Comfort has a mechanical handle that will pull out and swivel one of the rear seats towards the entering passenger, as shown in Figure 2.

Figure 2. A UD rear seat design in a Toyota Crown Comfort (Toyota, 2009).

It is worth noting that, aside from the small mechanical handle that unlatches the seat and allows it to rotate outward, the configuration of the seat is very similar to that of any other sedan. Though there is additional design effort needed to design this universal seat, the material and manufacturing costs would likely be only marginally higher than for a typical seat. An advantage of including these features early in the design process and integrating them into a universal product is the avoidance of the high cost of having to retrofit a vehicle later for disabled users.

Though seemingly simple to execute, these examples of successful UD serve as exceptions, not the rule, in common design practice. As it stands, a barrier to UD is lack of knowledge regarding its practice and the resources that are available to develop a UD product. In this paper, we present a framework for performing research that enables an understanding of product differences in the context of UD. Additionally, the framework allows for the recognition of these differences early in the design process. The focus is on the early recognition of differences and commonalities between typical and universal products as a way to recognize opportunities for creating product families that contain both types of products.

The remainder of this paper is organized as follows. The first section reviews related literature and background. The second section describes the research approach and method for supporting UD. Following this is a discussion and case study comparison of 20 product pairs, with one of the items in each pair being a typical product and the other a universal product. In closure, conclusions and future work are presented.

Background and Literature Review

This section presents background on the design of products for persons with a disability. Included is a discussion of different areas or types of design for persons with a disability and coverage of methods and research for developing methods that can enable effective design for persons with a disability.

In this article, we will primarily use the term Universal Design, or UD, to describe design for persons with a disability. The basic notion of universal design is developing a design that can be used equally well by people of any ability: in other words, it does not discriminate against users based on their ability. In this context, UD may be the most general term in use. However, the activity of designing for persons with a disability subsumes UD and has multiple other specific foci and names.

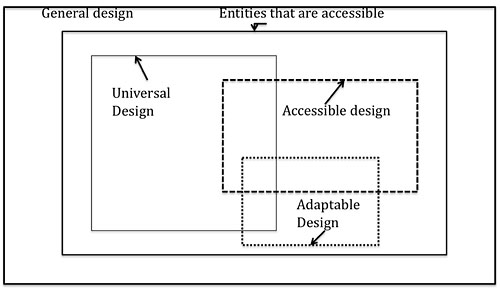

For example, transgenerational design focuses on design for older people, and rehabilitation design focuses on design for those with a new or temporary disability. Accessible design is another term used for describing design for persons with a disability. Accessible design is frequently used to describe specific modifications made to typical designs for people with disabilities, such as the addition of a ramp entry to a building. In this sense, both transgenerational and rehabilitation design are focused on design for those with some functional limitation, and thus they share common elements with UD (Connell, 1997; Hewer, 1995; Peloquin, 1994). Adaptable design is another type of design that can also be universal in the sense that it changes an existing product through modification of a part or component to make it easier to use (Erlandson, 2008). Figure 3 below illustrates how accessible, universal, and adaptable designs vary across the design space (Erlandson, 2008). A related model that represents different categories of designing for those with a disability is presented by Keates in work that develops some generally applicable approaches to universal design (Keates, Clarkson, Harrison et al., 2000).

Figure 3. A Venn Diagram illustration of the overlap and interaction of different types of design for persons with a disability (Erlandson, 2008).

The UD literature contains significant coverage of historical and social context. As an example, of the 62 chapters in The Universal Design Handbook (Preiser & Ostroff, 2001), 52 provide significant coverage focused on the history of UD, the rationale behind it, the legal issues, the documentation of workshops, etc. Notably, about 24 chapters provide descriptive guidelines and quantitative requirements for universal architectural design. Only about seven chapters contain guidelines, case studies, or other content that provides some insight into universal product design. The volume and emphasis of UD research publication mirrors the coverage found in The Universal Design Handbook (Preiser & Ostroff, 2001). A team of researchers organized through The Center for Universal Design at North Carolina State University has compiled seven principles that categorize aspects of UD (Connell, 1997). These seven principles are: 1) equitable use, 2) flexibility in use, 3) simple and intuitive use, 4) perceptible information, 5) tolerance for error, 6) low physical effort, and 7) size and space for approach and use. For each principle, several guidelines have been created. For example, principle 6 contains the guideline “minimize repetitive actions.” These principles have been well-received by designers in a range of disciplines. Additional research efforts have developed detailed and specific methods both for applying and evaluating the impact of these seven principles of universal design (Beecher & Paquet, 2005).

More specific guidelines have been developed with a focus on specific applications or product domains. The field of architecture serves as an example of an area in which there has been significant advancement in specific efforts to develop UD. Though universal design in architecture is not a solved problem, there is a large and high-quality set of UD resources available for architectural design (Davies, 1994; Freschette, 1996; Herwig, 2008; Null & Cherry, 1996; Peloquin, 1994; Vavik, 2009; Winter, 1997). The materials available include qualitative guidelines as well as quantitative parametric guidelines, such as for room layouts, counter heights, dimensional requirements for appropriate sight lines in large classrooms, etc. The available guidance for universal architectural design far surpasses what is available for universal product design.

Housed in the Center for Inclusive Design and Environmental Access (http://www.ap.buffalo.edu/idea/) at the University of Buffalo is an active group of researchers who focus on UD (Danford, 2003; Feathers, 2004; Langdon, Persad, & Clarkson, 2008; Steinfeld, 1990). Though this group is focused on architectural design and its members come from architectural backgrounds, they have also undertaken UD research on appliances and other applications that extend to product design.

Within product design, there have also been significant efforts to develop specific guidelines for UD. Panasonic, for example, focusing on its own product line, has developed the following guidelines: 1) easy-to-understand operation, 2) space to support easy access, 3) uncomplicated displays and indicators 4) peace of mind and security, 5) natural posture and ease of movement, and 6) consideration of how product is used and maintained (Panasonic, 2010). Vanderheiden (1997) has also developed a set of guidelines for the design of consumer products. These guidelines tend to focus on products related to electronic communication or information technology, but should be extendable to product design in general.

A team of researchers at the University of Cambridge has produced implementable results for inclusive design or UD (Clarkson, 2008; Clarkson, Coleman, & Keates, 2003; Clarkson, Langdon, & Goodman-Dean, 2008; Waller, Landon, & Cardoso, 2008). The focus of this research group has been on modeling user groups, creating product assessment methods, and extending the needs of UD to modern product design processes. The results of the Cambridge team are the most directly applicable to product design. Their efforts have been primarily focused on user modeling, on user centric differences between typical and functionally limited users, and on the design challenges of accommodating the functionally limited user. In contrast, the work presented in this paper is focused on the product and product-user interplay. Our research focus is on design activity slightly downstream in the design process from the Cambridge group. Given that the designer knows the disabled user has functional limitations, the next step is to determine how the product must change.

Keates proposed a seven-step approach for UD by modifying the traditional three-step design approach (Keates & Clarkson, 2003). The first two levels of the seven-step approach parallel the first two phases of a traditional design method. However, phase two is actually broken down into levels 3 through 5 in the 7-level design approach. In the 7-level approach, user perception, cognition, and motor function are additional elements introduced into a traditional design method to make it universal. Level 3 describes the user’s perceptions of the product or how the physical layout of the product affects user interaction. Often, anthropometric, ergonomic and empirical data from trials are needed to complete design at this level. Level 4 focuses on the user’s mental or cognitive interaction. Cognitive walkthroughs are used to correlate user system behavior to user expectations. Thirdly, level 5 focuses on user input or interaction with the product and relies on similar techniques as those used at level 3 to address design at this level (Keates & Clarkson, 2003).

Developing specific modules to modify products so that they become universal has been posed as a strategy for universal design (Clarkson et al., 2003; Moon & McAdams, 2009). Initial work has been reported on mathematical methods that explore tradeoffs in a module-based universal product family scenario (Moon & McAdams, 2009). This work assumes the designer has generated potential universal and typical products and is exploring ways to incorporate them into a product family. However, this work does not directly aid the designer in understanding product differences relevant to universal design. Though creating modular products that require minimized modifications to be made universal is a recognized approach to universal design, specific knowledge and methods for doing so do not exist (Clarkson et al., 2003).

Universal design is an active research area; nevertheless, formal methods for UD are limited in scope. Universal design is more of an objective than a systematic design approach. There is little in the way of a prescriptive approach to universal design that offers more detail than simply broad design objectives (Bowe, 2000). As an example, though the seven principles of universal design provide high-level guidance, they provide more of an evaluation aid than a design or synthesis aid for product design. Take for instance principle 6, which calls for products to be designed for low physical effort. Minimizing repetitive actions helps to reduce required effort, but how does one design a product so that repetitive actions are minimized and thus low physical effort is needed? Similarly, the consumer product guidelines from Vanderheiden are better suited to product evaluation than synthesis. For example, guideline I-2 calls for maximizing the number of people who can still find the individual controls or keys on a product if they cannot see them. To help synthesize a solution that achieves such a goal, this guideline includes suggestions for shapes of computer keyboard keys (or similar items) that will allow someone with a sight limitation to locate the correct key. As stated by the compilers of the seven principles: “…the practice of design involves more than consideration for usability. Designers must also incorporate other considerations such as economic, engineering, cultural, gender, and environmental concerns in their design processes” (Connell, 1997).

As extensions to high-level principles of universal design are developed, challenges remain. Considering the lack of education and tooling that prevents a company from easily implementing UD, companies need a quick, visual, and easy-to-understand tool, one with associated product examples and case studies, in order to feel more comfortable implementing universal design techniques. Designers want to know how to use the plethora of information about universal design in a more systematic way (Lebbon & Coleman, 2003).

As methods for UD are developed, they need to remain user centric. Designers are frequently unaware of the different customer preferences of those with different physical and mental disabilities. Thus, the designer is uncertain how to incorporate universal design into the design process (Cooper, 1999). Moreover, designers tend to work reactively rather than proactively. In other words, while a designer may be able to react to a definite set of customer needs and focus on satisfying them, what is needed in the case of universal design, is for a designer to be able to focus proactively on how a product’s capabilities will work with a variety of consumers (Stephanidis, 2009).

In summary, significant effort has been put into improving design for those with a disability. Results of the general research are substantial and range from efforts to develop a deeper understanding of the user, to high-level evaluation principles, to the application of specific guidelines for some areas such as architectural access. Nevertheless, there is still opportunity for significant contributions to be made with user-centric design tools that are focused on early design issues and decisions, that integrate with existing design processes, and that create a strong user-centric focus.

Product Analysis Framework and Research Approach

Our interest is in the early stage of the design effort, when product function is being established and solution concepts are being generated to provide that function. Our goal is to understand the differences and similarities in typical and universal products, and to be able to do so early in the design effort. Though beyond the scope of the work presented here, this interest is related to a future goal of creating product families that include typical and universal products built on some common platform. Thus, understanding the relationship between user activity, disability, and common and differing product characteristics is important.

Here we develop an analysis framework that allows the comparison of two or more products that fulfill the same overall need. The comparison is focused on the results of decisions that are made early in the design process, i.e., what functions the product must have and what forms and characteristics will best provide that functionality. The framework and analysis method are illustrated here with an example.

Product Analysis Framework

We will use the term product pair to refer to two products that satisfy the same high-level need or provide the same overall black box functionality but that differ in ease of use for someone with a disability (2002). Figure 4 illustrates a product pair of utility cutters. The Fiskars Rotary Cutter and a typical box cutter provide similar paper and cardboard cutting features, but the Fiskars Rotary cutter has features that make it preferable for users with reduced hand functioning.

Figure 4. A product pair of a Fiskars Rotary Cutter (above) and a standard box cutter (below).

As product pairs are analyzed, we want to compare them in terms of attributes crucial to making the product accessible and relevant to decisions that are made early in the design process. Thus, we will compare product pairs based on differences in functionality, morphology, and parametric realization.

A parametric difference between a typical and universal product refers to two products that could be described with the same parameterization, but have a differing value for some parameter. Parametrically different products exhibit common detailed functionality, solution principle, and form.

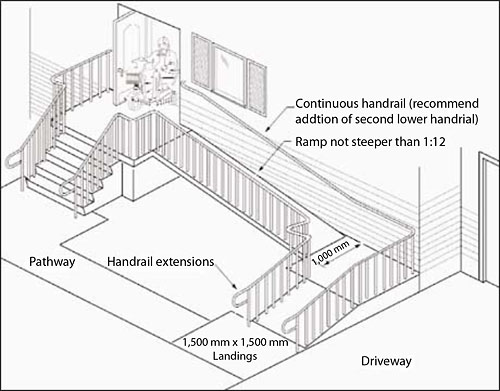

A sloped ramp entrance can be used to illustrate a parametrically different product pair in the context of UD. For example, to be accessible, the slope of the ramped entrance should not be greater than 1:12 (ADA, 2010). A ramp with a steeper slope would be a typical product in this case. Figure 5 and Figure 6 show two architectural systems that provide the same overall use, detailed functionality, and morphology, but, in the context of one being accessible and the other not, the difference is parametric.

Figure 5. A steep ramp, with a slope greater than 1:12, illustrating an inaccessible entrance.

Figure 6. A shallow ramp creating an accessible entrance. This ramp illustrates a parametric difference from the ramp in Figure 5.

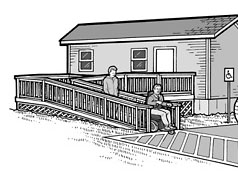

A morphological difference refers to two products that share the same detailed functionality but do not clearly exhibit a common parameterization. The two products exhibit a different solution principal, form, or geometric topology. Again, using a building entrance as an example, a ramp and a stairway can be used to illustrate a morphologically different product pair. Figure 7 shows an inaccessible entrance based on a step morphology. Figure 8 shows an entrance using a ramp morphology.

Figure 7. An inaccessible building entrance based on a stair morphology.

Figure 8. An accessible building entrance illustrating a morphological difference from the stair-based entrance in Figure 7.

A functionally different product pair indicates the addition or deletion of a product subfunction, or the change of some product subfunction, to improve its accessibility. The addition of a function may be in addition to other parametric or morphological product differences.

A wheel chair lift in addition to, or in place of, stairways at a building entrance is an example of a functional difference. The lift adds a new set of functions to make the building entrance accessible. Figure 9 shows an inaccessible stairway. Figure 10 illustrates a functional change, with the addition of a wheel chair lift, to make the stair entrance accessible.

Figure 9. An inaccessible stair step.

Based on the notions of product pairs, functional differences, morphological differences, and parametric differences, we want to compare product pairs in the context of user activity and product function. To do this, we have combined activity diagrams and functional models into a single representation that we will term an action-function diagram. Before introducing the action-function diagram, activity diagrams and functional models will be briefly reviewed.

Figure 10. An accessible building entrance that illustrates a functional difference from the stair-based entrance in Figure 9.

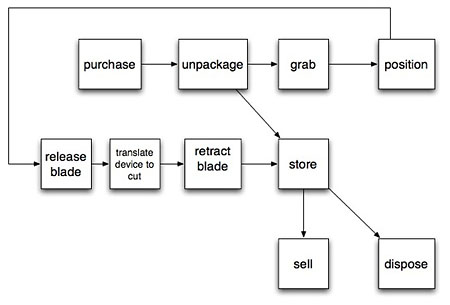

An activity diagram is a sequence of user interactions from purchase to recycling or disposal (Otto & Wood, 2001). This sequence may include parallel or series actions. A series of actions implies that one action must occur before another, whereas a parallel action implies that two actions occur simultaneously. Activity diagrams model the entire range of user-product interaction for the purpose of creating a better design for the product for each user activity. An example activity diagram for a typical box cutter is shown in Figure 11. The activity diagram shows the user interaction process from purchasing and unpacking the cutter to cutting cardboard with it.

Figure 11. An example of an activity diagram for a box or paper cutter.

A functional model is a graphical depiction of detailed product functionality. Functional models include functions, generally represented as verbs, which describe the desired transformations of flows, which are generally described using nouns. The process for creating a functional model depends on the modeling methodology chosen, but in general involves the following basic steps:

- Create a black-box model that includes the overall functionality of the product along with external flows.

- For each input flow in the black-box model, identify the sequence of functional transformations that are required to produce one or more of the output flows.

- Aggregate these function sequences into a complete functional model for the product.

- Assess the model’s coverage of customer needs and system requirements; add functions/flows or decompose as required.

A range of reasons for creating a functional model during product design are detailed by Otto and Wood (2001). In general, the primary reason is to create a solution-neutral method of representing what a product needs to do without assuming how it is going to do it. The mapping of what to how represents the remainder of the conceptual design process.

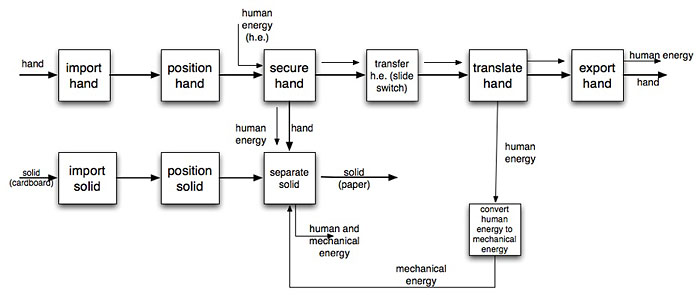

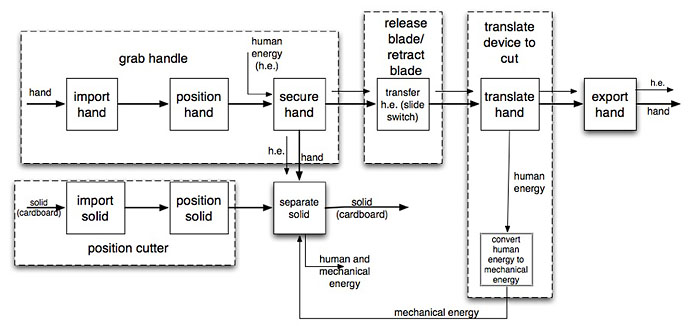

Frequently, functional models use function and flow terminology from the Functional Basis in order to maintain consistency from one product to another (Hirtz et al., 2002). A functional model for a standard box cutter intended for a typical user is shown in Figure 12.

Figure 12. A functional model for a standard box cutter.

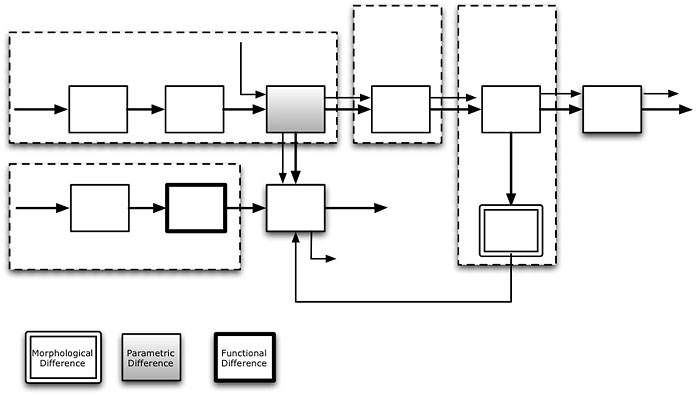

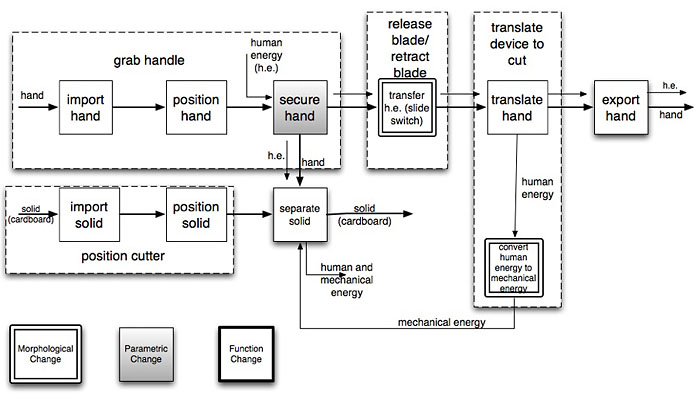

Figure 13 shows a template for the action-function diagram. In an action-function diagram, user activities are represented by dashed rectangles, with related functions clustered within each activity.

Action-function diagrams are created by analyzing the interaction of the user and the product. Specifically, they represent what product functions are needed for, or correspond to, user activity. For example, in this utility cutter example, the product function of import hand is needed to support the user activity of grab. Each user activity and product function are compared and analyzed. Then, the product functions are grouped with their user activities. User activities are shown in the action-function diagram to distinguish them from product functions. Using this sequence of activities, the activity diagram is combined with the functional model to create a single graphical representation of a user activity and a product function that is thus user centric and makes available information that is needed during the early stages of design.

With the specific goal of understanding the design differences between universal and typical products, action-function diagrams include an indication of the differences between the typical and universal products being compared as well as the user activities and product functions. Different product functionalities are indicated by a bold-lined function box. Common product functions but different morphologies are indicated by a double-lined function box. Common product functions and morphologies with different parametric implementations are indicated by a shaded function box. In cases where the typical and the accessible, or universal, products are the same, the function box is depicted using a standard line. The way in which these differences are represented in the action-function diagram is shown in Figure 13.

Figure 13. Generic template for an action-function diagram. An action-function diagram is the combination of an activity diagram and a functional model together into a single representation.

Dependent on the product pair analyzed and the design changes embodied to improve accessibility, the full range of parametric, morphological, and functional differences may not be present. Such a case is reflected in the action-function diagram by the absence of functions indicating change in the shaded, double-lined, and bold-lined function boxes.

Research Approach

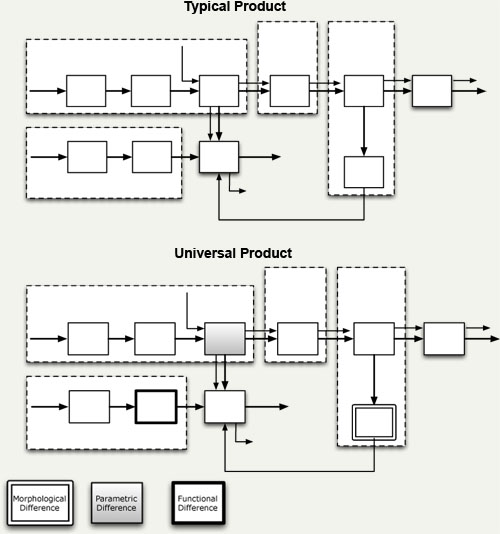

To explore differences between typical and universal products, the following approach was used: The first step was to identify a product pair. For each product pair, a common activity diagram was constructed, then a functional model made for both the typical and the universal product, then the functional models and specific products were compared. The activities were performed using tabular comparisons of the action-function diagrams to highlight the differences and similarities between the product pairs. A template table used to compare products is shown in Figure 14. In the general case shown in Figure 14, the universal product exhibits a parametric, morphological, and functional change. These changes are shown in the universal product action-function diagram.

Figure 14. Product pair action-function diagram template.

The products were carefully analyzed in terms of differences as they pertained to improved usage for a user with a disability or reduced functioning. If the impact of a design difference on usage was not clear, physical testing was performed.

We illustrate the design and analysis framework and approach with the example of a paper and cardboard cutter product pair, in this case the Fiskars rotary cutter and a standard box cutter, as shown in Figure 12. Both products provide the same overall usage of cutting but are different in their embodiment.

To start with, the rotary cutter has a more ergonomic handle. In this example, the handle, which provides for secure hand functioning, is based on the same basic principle, but is shaped differently, that is, more ergonomically, for the universal cutter. Thus, this difference is shown as a parametric change in the action-function comparison shown in Figure 15.

The rotary cutter has a circular blade with a guard, whereas the standard box cutter has a retractable angled blade. The difference in blade shape and blade motion impact the effort needed to cut. The rotation of the circular blade naturally adds some sawing motion to the material-blade interface, reducing the total force needed to cut as the user draws the cutter across the paper or cardboard. Also, the rotary cutter can cut with a pushing away motion, whereas the traditional utility knife only works well with a pulling motion. This represents a morphological difference, as rotating is a different physical principle for cutting than just pulling the blade through the material to be cut. The action-function diagram shown in Figure 15 represents this morphological difference in the solution of the convert human energy to mechanical energy function.

The blade extension and retraction design of the cutters is also significantly different. There are two switches to lock and unlock the blade for the rotary cutter, whereas only one switch is provided for both extending and retracting the blade for the standard box cutter. In the case of the rotary cutter, the blade extensions and retraction switches are both activated with a simple pushing in, or pushing down, motion on a single axis of travel. The blade on the rotary cutter is spring loaded to snap back into place when the retraction switch is pushed. For the traditional utility knife, the user pushes the switch into the knife to release a lock, then pushes it forward along the length of the knife to extract the blade. The simple pushing-in motion of the universal cutter is easier to accomplish then the push-in-then-push-forward motion of the standard cutter. Additionally, the actual force needed to push the switches on the rotary cutter is less than the force needed either to push in or push forward on the utility knife.

Both the typical utility knife and the rotary cutter provide the function of transferring human energy into the device to move the blade. The difference is categorized as morphological as there is not a clear parametric representation that encompasses both concepts.

The differences between the two products are shown in the action-function comparison in Figure 15. Of note in this example is that the universal and typical cutters are functionally equivalent: the universal cutter is made accessible through changes in specific form solutions used to solve product functions and the parametric realization of these form solutions. These parametric and morphological differences are shown in the rotary cutter action-function diagram in Figure 15. Continuing with the example application of the action-function diagram, no functional change is shown. This example illustrates that product accessibility can be improved without the addition of new product functions.

An action-function diagram for a typical utility cutter.

An action-function diagram for the Fiskars rotary cutter.

Figure 15. Action-function product pair comparison for the standard utility cutter and the Fiskars rotary style cutter.

(These diagrams are shown here in a single column for readability.)

Case Study and Results

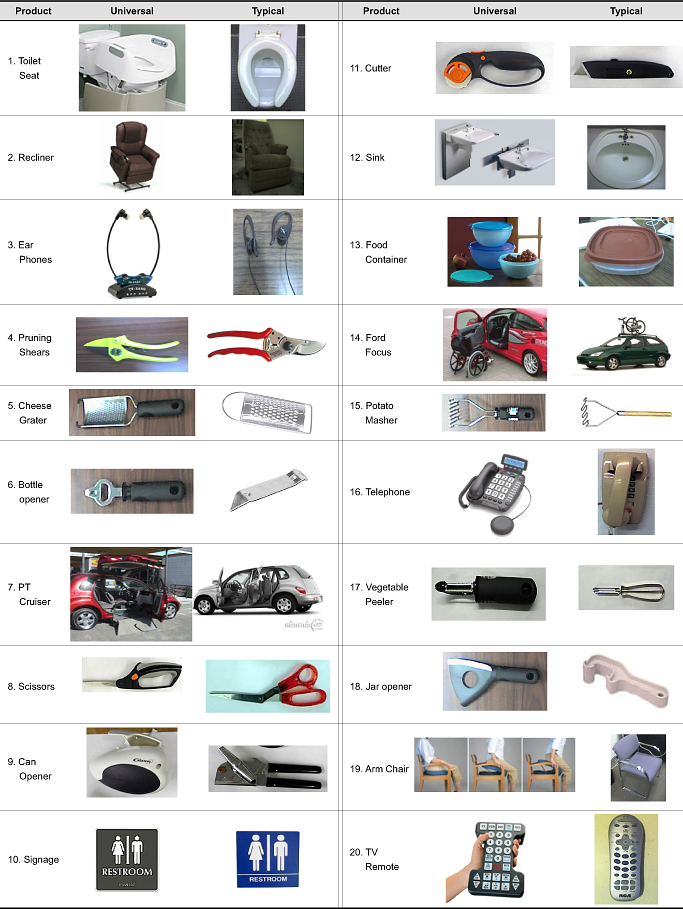

Twenty product pairs ranging from automobile interiors to scissors are compared in this study. Products marketed or generally accepted as universal or accessible were chosen along with similar typical products to form the product pairs. Most of the products are handheld kitchen utensils. However, diverse products such as recliners, sinks and automobiles are also included. The vehicle product pairs include products that have been modified to improve user egress and ingress accessibility. The Appendix shows a table of the 20 product pairs studied.

As with the paper and cardboard cutter product pair analyzed above, a comparison using the action-function diagram and experimentation was performed on each product pair. In summary, a functional model for both products in each pair, along with the activity diagrams and the action-function diagrams, were created, and then the two action-function diagrams were compared and analyzed. The paired products were analyzed to determine where the products differ in the context of making the universal product usable, or more easily used, by someone with a disability. Results are summarized and discussed here.

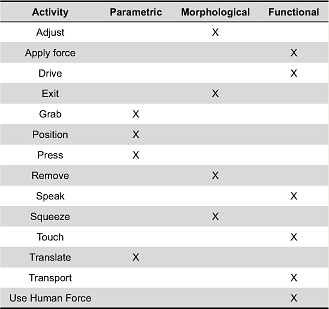

In studying the product pairs, the user activities associated with parametric, morphological, or functional differences between the products were: adjust, apply force, drive, exit, grab, position, press, remove, speak, squeeze, touch, translate, transport, and use human force. It was found that the product design changes or differences occurred primarily where direct contact with the product took place and were primarily relevant to reduced hand strength and motor functioning.

The user activities for which there were found no associated differences between the products were: approach, attach, connect, demolish, dispose, insert, install, look, program, purchase, read instructions, recycle, release, replace, retract, return, sell, stand, start, store, stop, twist (turn), unpackage, wait, and walk. These activities generally occur early or late in the product life cycle.

These results appear to be based on what has been done in universal design practice as opposed to a fundamental result of what needs to be done in a broad and general context. Such a result is consistent with the sample size of the study and the challenges and complexities of universal design. Also, during the study, the authors noticed that though some activities did not relate to design differences they should have. For example, although the product pair solutions for the activities of read instructions and unpackage were effectively equivalent for product pairs, nevertheless, the instructions were not always particularly accessible to someone with reduced vision functioning. Similarly, the heavy plastic blister packs that many of the products come packaged in are difficult to open for a user with reduced hand strength and motor function.

Table 1 shows the specific type of design change correlated with each specific activity. Complex activities such as drive and speak result in a more comprehensive change (function). Simple activities, such as grab, position or press, result in less comprehensive parametric changes. Based on the product pairs studied, no specific conclusions on trends regarding what activities are related to what specific types of changes can be drawn.

Table 1. Activity and Design Changes.

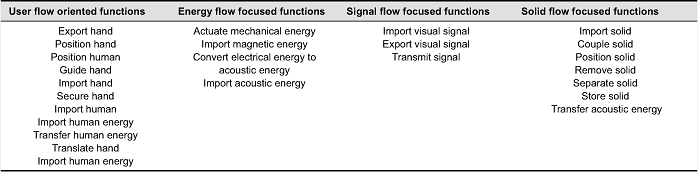

Table 2 indicates which functions did not feature a parametric or morphological difference, and were not a functional difference in a product pair. These functions were identified by performing the analysis method described in the section above. The action-function based analysis was performed, and the action-function diagrams for product pairs were compared and the functions that did not change between the typical and universal products were identified. Many of these were import or convert functions. In general, these functions are internal to the functional model, although this is not always so, as exemplified by the position hand and guide hand functions.

Table 2. Functions not related to any product pair design difference.

(The functions have been categorized for organization and readability. No conclusions are drawn from the categorization.)

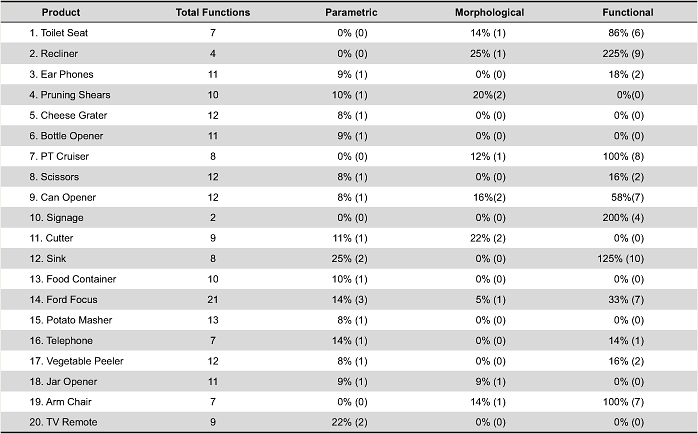

Table 3 summarizes the parametric, morphological, and functional differences between the universal and typical products analyzed. The percentage differences reflect the changes in the product at a functional level using the typical product as the basis for comparison. Table 3 includes the total functions in the base comparison product to provide a context for quantity of change that is expressed as a percentage. For example, a parametric change in one function out of a total of ten functions in a product would result in a 10% parametric change. The measure uses the typical product functionality as a base for comparison, thus enabling for greater than 100% change. For example, the typical recliner only had four functions, whereas the universal recliner had an additional nine functions, thus resulting in a 225% functional difference.

In the study, 75% of the product pairs featured a parametric difference, 45% a morphological difference, and 60% a functional difference. By calculating the average of the parametric, morphological, and functional change columns in Table 3, some indication of the degree of difference between the typical and universal products can be determined. For all 20 product pairs, the average parametric difference was 9.7%, the average morphological difference was 6.1%, and the average functional difference was almost 33%.

Table 3. A summary of differences between the typical and universal products analyzed.

(The number in parentheses indicates the raw function count in which a change occurred.)

The fact that the average functional differences were about six times greater than the parametric or morphological differences indicates that universal design needs to be considered early in the design process. Product function drives many early design decisions, including product architecture. Whereas parametric redesigns are often cost effective and can be done toward the final stages of product design, changing product function is a more complex and expensive task, one that impacts the solution concepts generated and that is tightly coupled to customer needs.

Of the products studied, the simple products feature less functional change than the complex products. For example, the cheese grater, bottle opener, potato masher, food container, and jar opener feature parametric changes in being made more accessible. By contrast, the sink, can opener, and recliner feature significant functional changes. The universal products with added functionality often feature functions that replace what the user provides when using the typical product. For example, the universal can opener features a motor as a means for enhancing the cutting motion and torque that the user provides when using a typical can opener. Similarly, the recliner features added functionality that essentially stands the user up.

Conclusions and Future Work

In this paper we have explored the relationship between user activity, product function, and product form as it pertains to differences in typical and universal products. Specifically, we explored a research framework that uses the formal design methods of activity diagrams and functional models. We combined these methods into a single graphical representation called an action-function diagram that allows the user to see functional, morphological, and parametric differences between a typical and a universal product that have the same general use. Using this approach, 20 products were studied with an aim to understanding the trends in functional, morphological, and parametric differences between typical and universal products that have the same general use.

The action-function diagram provided a clear, repeatable framework for analyzing the differences that pertain to typical and universal products. Though used in this study as a research framework, the action-function diagram is applicable to actual design activities. The diagram clusters product functions as they relate to user activity, thus aiding the designer in identifying activities, and user limitations, for which a product requires a specific functional, morphological, or parametric embodiment.

In design practice, the action-function diagram would integrate with the usage of activity diagrams and functional models during the conceptual design phase. As designers determine customer needs, user activity, and product function, the action-function diagram would be used to better understand the interplay of user activity and product function. Specifically, in the context of performing UD, the activity diagram can focus a designer’s attention to product function as it interacts with a user activity for which the user is disabled.

In the case study presented here, the action-function diagram was used to analyze primarily products of limited complexity, using the term complexity here to indicate products of limited total part count and limited functionality. Exploring the application of the action-function diagram with a comprehensive sample of complex products and drawing complete conclusions is beyond the scope of the work presented here. But, based on experience gained doing this research, some expectations for such an activity can be projected. The action-function diagram is used to analyze the interplay of user activity and product function. The process of creating action-function diagrams for more complex products would remain essentially the same. As user activity and product function become more complex, it is expected that the action-function diagram would also become more complex. However, the degree to which an action-function diagram becomes more complex does not directly correlate with a more complex product. As products increase in complexity, much of the complexity is, from a user activity perspective, internal to the product. For example, a passenger car may be significantly more complex than a riding lawnmower, but user activity in relation to operation of the passenger car is only marginally more complex. Thus, the complexity in creating action-function diagrams is contained in the complexity of creating the functional model and is not inherent in the creation of the action-function diagram itself.

Within the products studied, the majority of differences between universal and typical products are related to user hand manipulation of the product. Functions that are internal to the product (those that do not have an exiting or entering flow that crosses the product boundary) generally remain the same for the product pairs studied. Additionally, boundary functions not related to human flow generally remained unchanged. In some sense, this result may be based on the product pairs selected for this study. Though further work remains to be done to fully understand the interplay of product function and user activity as it relates to UD, this work does reveal trends that seem likely to remain apparent regardless of the product set analyzed. For example, the trend of human flow being crucial is present in this study regardless of whether the human flow was a hand material flow (as in a kitchen utensil), a visual information flow (as in signage), or other human material flow (as in a recliner).

Universal design remains a challenge. Toward the goal of creating a fundamental framework for universal product family design, many questions remain. A deeper understanding of classes of products, classes of functions, classes of user limitation, and the interactions between these needs to be discovered so that designers can reason about integrating product functions and features into a universal product family. Using the framework developed here, further study could reveal what functions are common across a range of typical and universal products. With this knowledge, designers could extend current product family design methods to create universal product families that share these common elements as a product platform and extend to a product family with the same unique elements.

References

- ADA. (2010). Americans with Disabilities Act. Retrieved January, 27, 2010, from http://www.ada.gov

- Beecher, V., & Paquet, V. (2005). Survey instrument for the universal design of consumer products. Applied Ergonomics, 36(3), 363-372.

- Bowe, F. G. (2000). Universal design in education. Westport, CT: Bergin and Gavey.

- Cagan, J., & Vogel, C. (2002). Creating breakthrough products: Innovation from product planning to program approval. Upper Saddle River, NJ: Pearson Education.

- Clarkson, P. J. (2008). Human capability and product design. In H. N. J. Schifferstein & P. Hekkert (Eds.), Product experience (pp. 165-198). Boston: Elsevier.

- Clarkson, P. J., Coleman, R., Keates, S., & Lebbon, C. (2003). Inclusive design: Design for the whole population. London: Springer-Verlag.

- Clarkson, P. J., Langdon, P. M., Goodman-Dean, J., & Robinson, P. (Eds.). (2008). Proceedings of the 4th Cambridge Workshop on Universal Access and Assistive Technology. Cambridge, UK: Fitzwilliam College.

- Connell, B. R., Jones, M., Mace, R., Mueller, J., Mullick, A., Ostroff, E., Sanford, J., Steinfeld, E., Story, M., & Vanderheiden, G. (1997). The principles of universal design. Retrieved July 14, 2009, from http://www.design.ncsu.edu/cud/about_ud/udprincipleshtmlformat.html#top

- Cooper, A. (1999). The inmates are running the asylum. Indianapolis, IN: SAMS.

- Danford, G. S. (2003). Universal design: People with vision, hearing, and mobility impairments evaluate a model building. Generations, 27(1), 91-94.

- Davies, T. D., & Beasley, K. A. (1994). Accessible design for hospitality: ADA guidelines for planning accessible hotels, motels, and other recreational facilities. New York: McGraw-Hill.

- Erickson, W. A., & Lee, C. G. (2003). Disability statistics in the United States. Retrieved March 8, 2010, from http://www.disabilitystatistics.org

- Erlandson, R. F. (2008). Universal and accessible design for products, services, and processes. Boca Raton, FL: CRC Press.

- Feathers, D. (2004). Digital human modeling and measurement considerations for wheeled mobility device users. SAE Transactions, 113(1), 70-77.

- Freschette, L. A. (1996). Accessible housing. New York: McGraw-Hill.

- Goodman, J., Dong, H., Langdon, P., & Clarkson, P. J. (2006). Factors involved in industry’s response to inclusive design. In P. J. Clarkson, P. Langdon, & P. Robinson (Eds.), Designing accessible technology (pp. 31-39). London: Springer-Verlag.

- Herwig, O. (2008). Universal design: Solutions for a barrier-free living. London: Springer-Verlag.

- Hewer, S. (Ed.). (1995). The DAN teaching pack: Incorporating age-related issues into design courses. London: RSA.

- Hirtz, J., Stone, R., McAdams, D., Szykman, S., & Wood, K. (2002). A functional basis for engineering design: Reconciling and evolving previous efforts. Research in Engineering Design, 13(2), 65-82.

- Keates, S., & Clarkson, P. J. (2003). Countering design exclusion. London: Springer-Verlag.

- Keates, S., Clarkson, P. J., Harrison, L., & Robinson, P. (2000). Towards a practical inclusive design approach. In Proceedings of the 2000 Conference on Universal Usability (pp. 45-52). New York: ACM.

- Langdon, P. M., Persad, U., & Clarkson, P. J. (2008). Operationalising analytical inclusive design evaluation. In P. D. Bust (Ed.), Proceedings of the International Conference on Contemporary Ergonomics (pp. 279-284). London:.Taylor & Francis.

- Lebbon, C., & Coleman, R. (2003). A designer-centred approach. In J. P. Clarkson, R. Coleman, S. Keates, & C. Lebbon (Eds.), Inclusive design: Design for the whole population (pp. 500-519 ). London: Springer-Verlag.

- Moon, S. K., & McAdams, D. A. (2009). Universal product platform and family design for uncertain markets. In M. N. Bergendahl, M. Grimheden, L. Leifer, P. Skogstad, & U. Lindemann (Eds.), Proceedings of the 17th International Conference on Engineering Design (pp. 59-70). Glasgow, UK: Design Society.

- Null, R. L., & Cherry, K. F. (1996). Universal design: Creative solutions for ADA compliance. Belmont, CA: Professional Publications.

- Otto, K., & Wood, K. (2001). Product design: Techniques in reverse engineering, systematic design, and new product development. New York: Prentice-Hall.

- Panasonic. (2010). Universal design ideas. Retrieved March 8, 2010, from http://www.panasonic.net/center/tokyo/floor/floor_03/index.html

- Peloquin, A. A. (1994). Barrier-free residential design. New York: McGraw-Hill.

- Preiser, W. F. E., & Ostroff, E. (Eds.). (2001). Universal design handbook. New York: McGraw-Hill.

- Steinfeld, E., & Mullick, A. (1990). Universal design: The case of the hand. Innovation, Fall, 27-31.

- Stephanidis, C. (Ed.). (2009). User interfaces for all: New perspectives into human-computer Interaction. Hillsdale, NJ: Lawrence Erlbaum.

- Toyota. (2009). Toyota crown comfort. Retrieved January, 27, 2009, from http://toyota.jp/welcab/crowncomfort/kaiten/

- Toyota. (2010). Universal design showcase. Retrieved March 8, 2010, from http://www.megaweb.gr.jp/Uds/English/guide.html

- Vanderheiden, G. (1997). Design for people with functional limitations due to disability, aging, or circumstance. In G. Salvendy (Ed.), Handbook of human factors and ergonomics. London: John Wiley & Sons.

- Vavik, T. (2009). Inclusive buildings, products & services-challenges in universal design. Trondheim, Norway: Tapir Academic Press.

- Waller, S. D., Landon, P. M., Cardoso, C., & Clarkson, P. J. (2008). Calibrating capability loss simulators to population data. In P. D. Bust (Ed.), In Proceedings of the International Conference on Contemporary Ergonomics (pp. 291-296). London:.Taylor & Francis.

- Winter, S. (1997). Accessible housing by design: Universal design principles in practice. New York: McGraw-Hill.

Appendix

Product pairs of typical and universal products studied in this article.