Exploring the Composite Intentionality of 3D Printers and Makers in Digital Fabrication

Sowmya Somanath 1,*, Ron Wakkary 2,3, Omid Ettehadi 4, Henry Lin 2, Armi Behzad 2, Jordan Eshpeter 2, and Doenja Oogjes 3

1 Department of Computer Science, University of Victoria, Victoria, Canada

2 School of Interactive Arts and Technology, Simon Fraser University, Vancouver, Canada

3 Department of Industrial Design, Eindhoven University of Technology, Eindhoven, The Netherlands

4 Faculty of Graduate Studies, Ontario College of Art & Design University, Toronto, Canada

In this paper, we identify new relationships between technologies and people in the context of digital fabrication. Our research applies a postphenomenological lens to understand and identify such relationships by using the concept of intentionality, an idea that relates to how humans and technologies, in their corporeal sense, direct themselves at the world rather than their purpose of action. We conducted a study wherein we first modified four 3D printers that highlight technological intentionality by either reducing, redirecting, reshaping, or redistributing the CAD model and filament of a given print. Next, experienced makers were invited to print models with one of four printers and reflect upon the effects of the coupling between their intentionality and that of the 3D printer. We contribute descriptions for new ways to frame human-technology relationships within the context of digital fabrication and highlight three relationships with machines: anticipatory, itineration and resistance, and their implications.

Keywords – 3D Printing, Composite Intentionality, Makers, Postphenomenology, Human-technology Collaboration.

Relevance to Design Practice – We theorize the creative combination of the maker and 3D printer as composite intentionality to yield new characteristics of design practice and the role of digital fabrication technology.

Citation: Somanath, S., Wakkary, R., Ettehadi, O., Lin, H., Behzad, A., Eshpeter, J., & Oogjes, D. (2022). Exploring the composite intentionality of 3D printers and makers in digital fabrication. International Journal of Design, 16(3), 77-95. https://doi.org/10.57698/v16i3.005

Received Dec. 14, 2021; Accepted Dec. 1, 2022; Published Dec. 30, 2022.

Copyright: © 2022 Somanath, Wakkary, Ettehadi, Lin, Behzad, Eshpeter, & Oogjes. Copyright for this article is retained by the authors, with first publication rights granted to the International Journal of Design. All journal content is open-accessed and allowed to be shared and adapted in accordance with the Creative Commons Attribution 4.0 International (CC BY 4.0) License.

*Corresponding Author: sowmyasomanath@uvic.ca

Sowmya Somanath is an Assistant Professor in the Department of Computer Science at the University of Victoria, where she leads the Creative Experiences Lab (celab.cs.uvic.ca) and co-leads the Victoria Interactive Experiences with Information Lab (vixi.cs.uvic.ca). Her research is focused on leveraging and extending the richness and situatedness of people’s physical interactions with objects, other agents and technologies. She studies, designs and evaluates novel interactive experiences that can help diverse people accomplish embodied tasks in creative and/or safe ways.

Ron Wakkary is a Professor in the School of Interactive Arts and Technology at Simon Fraser University, where he is the founder of the Everyday Design Studio (eds.siat.sfu.ca). In addition, he is a professor in Industrial Design at Eindhoven University of Technology in the Netherlands. His research investigates the changing nature of design and human-computer interaction in response to new understandings of human-technology relations and posthumanism. Wakkary is the author of the book, Things we could design: For more than human-centered worlds (MIT Press, 2021).

Omid Ettehadi is an HCI researcher fascinated by new technologies, specifically how these tools can bring back control to the users and enhance their learning capabilities from their daily activities. Omid did his graduate studies at OCAD University, where he focused on using digital fabrication tools to facilitate experiences where end-users can use advanced documentation to improve their self-reflection on their making activities.

Henry Lin is a designer, fabricator, and maker at heart. Currently, he uses interdisciplinary knowledge to explore the bound of using digital fabrication and other prototyping techniques for research and physical model-making. Henry did his graduate study in Everyday Design Studio in the School of Interactive Arts and Technology at Simon Fraser University. His research focused on how to design electronics from the perspective of a research product, where research objects were used for long-term deployment.

Armi Behzad is a graduate student at the Everyday Design Studio in the School of Interactive Arts and Technology at Simon Fraser University. As an interdisciplinary design researcher, she is interested in more-than-human design as a new approach to exploring new methods for driving innovation and technological change toward a more diverse, inclusive, and sustainable world. Armi brings her critical thinking, design, and technical skills into her research and practice from her background and experience in architecture and creative technologies.

Jordan Eshpeter is a Ph.D. student at the Everyday Design Studio in the School of Interactive Arts and Technology at Simon Fraser University. His research explores more-than-human approaches to design ethics. Currently, Jordan is focusing on how ethics are negotiated, distributed, and enacted in the everyday practices of digital product design. His interest in design ethics and practice are motivated by his professional experiences as a leader and practitioner at digital product design studios.

Doenja Oogjes is a design researcher interested in indirect, accidental, surprising, and overlooked ways designed things mediate the everyday. She explores more-than-human thinking in design, currently focusing on textile fabrication. Doenja uses research-through-design, speculative design, and first-person design approaches. She is an Assistant Professor at the department of Industrial Design, Eindhoven University of Technology, and completed her Ph.D. research at Simon Fraser University.

Introduction

Domains such as human-computer interaction (HCI) and interaction design have introduced us to a plethora of new tools and technologies that are designed to serve, help, assist, and collaborate with people. Despite the varied range of roles assigned to technologies, much of the focus in technology design has been on creating machines that are functional, reliable, usable, or pleasurable (e.g., Greenberg & Buxton, 2008; Norman, 2013; Walter, 2011; Zoran, 2013). However, this stable description obscures the view that technologies can indeed be more than simply reliable or pleasurable and instead be arousing, spurring on imaginative uses (Sennett, 2008), be a collaborator with unique talents (Devendorf & Ryokai, 2015) or a connector, inviting people to continually build ties with the technology (Saegusa et al., 2016). Our general aim in this article is to theoretically explore such alternative roles for technology. More specifically, we focus on the role of 3D printers in digital fabrication. This aim is in line with the increasing degree to which a machine or tool is seen as actively shaping the outcome (e.g., Andersen et al., 2019; Devendorf & Rosner, 2017; Kim et al., 2017; Saegusa et al., 2016), and thus open up broader ideas of our relationship to machines, where we might start to consider interaction, not in terms of use but rather as something that is mediated, co-produced, cyborgian, or otherwise the result of combining the specific qualities of humans and nonhumans.

Our research is inspired by several projects that have demonstrated and explored alternative roles for machines in digital fabrication. For example, in the concept of digital craftsmanship, where new relationships to tools and technologies are sought, technologies help people create artifacts that one cannot yet imagine and get to only see through making (Andersen et al., 2019; Jacobs et al., 2016; Vannucci, 2020). Further, parallels have been drawn between digital fabrication and the active role of tools in craftwork such as pottery (Desjardins & Tihanyi, 2019; Tsaknaki & Fernaeus, 2016), carpentry (Dew & Rosner, 2018), shoemaking (Nachtigall et al., 2019), milling (Zoran, 2013), or textiles (Muslimin, 2010; Ooms et al., 2020; Van Herpt, 2015), in which the digital technologies are also seen to be potentially active in the creative process. In areas at the intersection of arts, social sciences, and digital fabrication, works such as Re-Deform/Being the Machine (Devendorf & Ryokai, 2015) and Arc (Saegusa et al., 2016) have explored how people respond to making processes wherein both humans and machines creatively contribute towards the fabrication task and informed by that, suggest new forms of machine-human collaborations. In what is known as Critical Making (Hertz, 2014; Ratto, 2011), attention is given to critically reflecting on the engagement with technological tools (and materials) in the process of making to learn, and so the tools can be said to be active in this form of critical knowing. Despite this past research, investigating such alternative roles for machines is relatively limited in digital fabrication, unlike other areas like generative music (Collins, 2003) or AI agents (Kivanç & Pasquier, 2019) or glitch art (McCallum, 2018; Menkman, 2011), and so is our primary interest in this article.

We draw on postphenomenology to help theorize the evolving relationship between humans and technology in creative digital fabrication. Postphenomenology is a philosophy of technology that focuses on the implications of technologies doing more than playing supporting roles, instead, technologies are seen as non-neutral, co-shaping, and sharing agentic qualities to perceive and act in the world with humans (Ihde, 2009). This is generally characterized as technological mediation, in which the relations between the human subject and the world are mediated via technologies (Rosenberger & Verbeek, 2015). However, Peter-Paul Verbeek (2008) further theorizes different forms of technological relations that go beyond mediation, to specify amongst others, the concept of composite intentionality. Composite intentionality describes the unique ways in which technologies and humans combine to direct themselves jointly at the world. Our study uses the concept of composite intentionality to theorize the role technology plays alongside humans in 3D printing, and we use it to analyze the empirical data we collected.

In this study, we theorized the creative combination of a maker and a 3D printing service as composite intentionality to see if we could yield characteristics of this human and technological assemblage (composed of a network of 3D printers and human operators) relationship that would also help us better understand the role of digital fabrication technology.

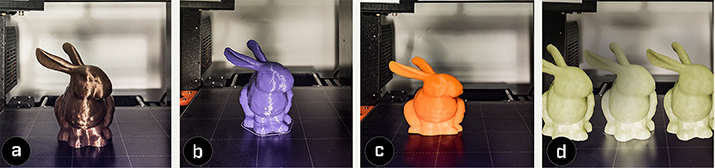

A key strategy was to amplify how technology, in our case—3D printers, can direct itself at the world. To do this, we engage in a form of material speculation to pursue our research goals in which the design of counterfactual artifacts facilitates what-if inquiries through design (Wakkary et al., 2015). The counterfactual nature of our study is that we uniquely configured four 3D printers that either reduce, redirect, reshape, or redistribute the CAD model and filament of a given print in ways atypical for a 3D printer (Figure 1). We use these capabilities as examples of possible intentionalities for 3D printers, including those connected to a network. We created a 3D printing service that allowed makers from different geographical locations to try out our printers and have the print delivered to them. We invited ten experienced makers to use our print service and qualitatively reflect on their experiences. We utilized composite intentionality to conceptualize the relations between makers and the 3D printing service and conducted a qualitative analysis of our interviews with the makers through this lens.

Figure 1. Prints embodying different machine intentionalities: (a) Dwindle printer - reduces the quality of print over time, (b) Breezy printer - redirects the printer’s nozzle based on wind data, (c) Postal printer - reshapes the model for shipping, and (d) Skimpy printer - redistributes filament across multiple copies of the object.

Our findings describe theoretically and empirically derived characteristics of human-technology relations within digital fabrication that include: a) opening a space for anticipation that accepts a role for technology to shape the outcome in surprising ways; b) that the relationship with the technology is one of itineration, a co-exploration of where the creative process can go; and c) there is resistance to the increased agency of technology in digital fabrication, which at times can be productive. We also describe how technological intentionality can be productively described within technology as an assemblage rather than a single technological artifact. At the conclusion of the paper, we discuss how our findings inform further research into the design of digital fabrication technologies and new creative practices, and how those characteristics can expand our understanding of the relationship between technologies and humans.

The contributions of this paper are: 1) theorizing the relationship of the maker and 3D printer through composite intentionality; 2) characteristics of composite intentionality in digital fabrication that includes anticipatory, itineration, and resistance; and 3) extending the definition of technology with respect to composite intentionality as a technological assemblage rather than a concrete technological artifact.

Composite Intentionality

Postphenomenology is a philosophy that expands the importance of technology beyond functionality or serving as instrumental objects. Central to this increased importance is that technology is seen to enact the relations between human subjects and their world via technology in what is referred to as technological mediation (Ihde, 1990; Rosenberger & Verbeek, 2015). Verbeek later argued that mediation is only one form of the relations between humans, technology, and the world; that postphenomenology also needs to account for the increasing entanglements with technology that go beyond mediation. One of these new forms of relations he labeled composite intentionality. Composite intentionality describes situations in which not only humans direct themselves at the world, what he calls human intentionality, but technologies also direct themselves at the world, what he calls technological intentionality (Verbeek, 2008). Given the importance of this theory to our study, we explain the key concepts we use in this article: human intentionality, technology intentionality, composite intentionality, and technology.

- Human Intentionality: For a postphenomenologist, the ontological relationship between humans and technologies is interdependent in that they mutually shape each other in terms of what it means to be human and technological within a given embodied situation. Our relation to the world is constituted through the embodied way we direct ourselves toward reality—what is referred to as intentionality. Intentionality describes how we, as corporeal or bodily humans, direct ourselves at the world as a matter of experiencing and affecting it (e.g., “I understand mobility from my experience of riding a bicycle”). It is important to note that the term intentionality is different from intention, wherein intention refers to the goals we have in mind when we act (e.g., “I rode my bicycle to the store because I wanted to get there more quickly”).

- Technological Intentionality: Postphenomenology extends phenomenological thinking by accounting for the role and importance of technology in our phenomenological worlds. Central to this extension is arguing that phenomenological intentionality can be applied to nonhumans, specifically technologies. Verbeek (2008) refers to this as technological intentionality. For example, he describes how an omnidirectional microphone records background sounds that humans typically filter, revealing a wider range of different sounds. The microphone is embodied within its own specific material and technological arrangements, and it is in this way that it uniquely, in comparison to humans, directs itself at the world to listen as only it can.

- Composite Intentionality: Composite intentionality is the combination of technological intentionality with human intentionality. In the case of audio recordings from an omnidirectional microphone, the recorded sounds that humans typically filter out could be used in biological research in which field recordings of wildlife bring together human and technological structuring to make sense of experiences of the world. Verbeek (2008) also offers a creative example, the work of the photographer Wouter Hooijmans whose night photographs are a result of hours-long low light exposures that “blend together an infinite number of visual impressions into one single representation of the world, which the human eye could never produce itself” (p. 394). For Verbeek, composite intentionality makes accessible “ways in which technolog[ies] ‘experience’ the world” (p. 393) that are then combined with human perception and embodiment to directly affect or shape outcomes like a photograph of a meteor shower in ways that humans cannot shape alone.

- Technology: In postphenomenology, the term technology refers to specific technological machines or concrete technological artifacts like a telescope, camera, or Google Glass (Ihde, 1990; Rosenberger & Verbeek, 2015; Verbeek, 2008). While we assume a similar meaning of technology in this article and we refer to 3D printers as technology, it is important to note that we configured our 3D printers in ways that went beyond the concrete artifact of the physical machine to include the network of the Internet and even the broader socio-technical system (and service) of our printers. As we discuss later in the article, this shift from the traditional postphenomenological definition of technology resulted in a contribution in which we see technological intentionality as better viewed within an assemblage of technologies and the various mediating layers that constitute any given technological artifact.

It is important to note that postphenomenology is not the only philosophical perspective that sees the relationship between humans and technologies (or nonhumans more broadly) as irreducible. For example, Actor-Network Theory describes the relationship as symmetrical in which humans and technologies are equal actors in networked relations (Latour, 2007). In New Materialist or Posthuman views, shared phenomenological intentionality with the world results in common human and nonhuman agentic capacities (Bennett, 2010; Coole, 2013). In Haraway’s (1991) concept of the cyborg, the biological and technological are coupled in ways that shift subjectivities past anthropocentrism. The focus of postphenomenology on technologies, as opposed to nonhumans and materials more generally, makes it well suited to our approach in this article. More specifically, postphenomenology sees the role of technology as compositional, in which intentionality is shared between humans and technologies.

In this study, we specifically focus on the ways technologies, i.e., 3D printers in the form of a print service, can direct themselves at the world in combination with humans. More specifically, we focused on how the technological assemblage of 3D printing is directed toward reality and constitutes itself as a nonhuman maker and how, through joint composition with human makers, this can shape making. Composite intentionality helps theorize the unique configuration of the human makers and digital fabrication machines by offering insightful language and concepts to analyze how this combined intentionality shapes the process and outcome.

Related Work

In the following sections, we briefly discuss literature within two related areas to our study. Given that postphenomenology is nonhumanist in its approach, we look to other nonhumanist framings of technology in design research and then discuss specific examples of technology in digital fabrication related to our work.

Nonhumanist Framings of Technology in Design Research

Drawing on non-humanist, post-anthropocentric, or posthuman philosophies, which includes postphenomenology, is not new to design (e.g., Barad, 2007; Bennett, 2010; Borgmann, 1987; Braidotti, 2013; Haraway, 1991, 2016; Ihde, 1990; Latour, 1993; Verbeek, 2011). Recent design research has integrated concepts such as the cyborg (Bennett et al., 2016), hybridity (Devendorf & Rosner, 2017), performativity (Leahu & Sengers, 2015), mediation (Dalsgaard, 2017; Hauser et al., 2018), agential realism (Frauenberger, 2019), agency (Wakkary et al., 2017), natureculture (Smith et al., 2017), posthumanism (Wakkary, 2020, 2021), and nonhuman participation (Behzad et al., 2022; Oogjes & Wakkary, 2022).

Collectively these works emphasize a more entangled perspective of interaction and have further allowed for investigations into the agency, politics, and care or concerns of things themselves. Underlying these arguments is the shared belief in the mediating role of technologies, and, similar to our research here, previous work has investigated this particular relation with technologies. For example, Jenkins and co-authors explore the idea of object-oriented publics to particularly inquire into the agentic discourse between people and computation (Jenkins et al., 2016) from a design perspective: how computing’s agency is made material. Pierce has presented a range of works exploring how the design act of materializing (e.g., of energy, of internet networks) allows for exploring and generating mediated relations. Oogjes and Wakkary (2017), through video, explore these technologically mediated relations in their explorative work on Videos of Things by considering how different narrative strategies can aid in speculating on, anticipating, and synthesizing relations. Hammad et al. (2019) explored the cognitive and physical aspects of blending human and nonhuman experiences by applying performance-based arts techniques to help people transition into and out of technology-mediated cyborg experiences. Andersen et al. (2019) characterize craft and technology as a form of crafts-machine-ship in which autonomy is shared between craftsperson and machine. Dalsgaard (2017) introduces a framework for understanding the role of design tools as instruments of inquiry in how they facilitate perception, conception, externalization, knowing-through-action, and mediation. Finally, Wakkary (2021) theorizes the idea of designing-with, a design practice in which humans share center stage with nonhumans to cohabit a more-than-human world bound together materially, ethically, and existentially.

These works show how these philosophies of technology allow for exploring what they can reveal about our relations to technology. Wakkary and co-authors (2017) consider what a non-human-centered inquiry into IoT technologies may reveal by asking: “what is it like to be a thing on the Internet?” The Morse Things are a series of networked ceramic bowls and cups that communicate to each other in Morse Code to explore this question. These works also highlight how there is an opportunity to learn from and be surprised by thing-oriented perspectives. Leahu’s (2016) reading of the Google inception project illustrates this well. This project inverted neural network systems for image recognition to generate visuals that represent the images it was trained to recognize. According to Leahu, one particular visualization surprised the engineers: the representation of a dumbbell. In generating a representation of a dumbbell, a free weight or piece of equipment used in weightlifting, the system included not only the dumbbell, but also (parts of) human arms. Leahu reframes this instance, which was considered a failure or a glitch of the system, as an opportunity afforded by technological intentionality for investigating the relations that constitute what we frame as distinct entities like dumbbells or arms.

The implication of this role is important and raises a host of issues, including agency and control (Devendorf & Ryokai, 2015), ethical making (Campbell & Somanath, 2018), distributed skills (Kim et al., 2017), and bidirectionality (Kim, 2017). Our paper builds on these examples and aims to contribute a set of characteristics of human-technology relations that theoretically account for nonhuman actions and can be experienced empirically in digital fabrication.

Roles of Technology in Digital Fabrication

In the area of digital fabrication, technologies have taken on several roles, such as passive entities that can operate under exacting terms and conditions in reliable ways (e.g., Mueller et al., 2013; Rivers et al., 2012; Weichel et al., 2014; Willis et al., 2010; Zoran, 2013) or machines to which complex or tedious tasks can be delegated (e.g., Boucher & Gaver, 2017; Kim et al., 2018; Magrisso et al., 2018; Weichel et al., 2015; Zheng et al., 2017). Building on these past works, we extend our exploration to less-explored relationships between technologies and people in digital fabrication.

For example, Kimet al., (2017) explored a model that empowers machines in making processes and, with colleagues, explored through design narratives the idea of machines as co-designers. Others have extended critical speculations to materially engage creative projects and machines that both problematize and expand the relations between humans and machines in digital fabrication. For example, Saegusa et al., (2016) developed Arc to investigate the multiplicity of roles of a fabrication machine as a copier, translator, and connector. Similarly, Devendorf and Ryokai (2015) inverted the typical relations in digital fabrication so that the human operator becomes part of the 3D printer to humanly perform with machine augmentations in the 3D printing process. In subsequent research, Devendorf et al. (2016) theoretically inverted the relations of maker and machine by seeing the role of passive technologies as anthropocentric and the need to explore increased nonhuman agency as a post-anthropocentric approach to digital fabrication. Lastly, Devendorf and Rosner (2017) utilized technofeminism to help articulate the post-anthropocentric fabrication process as a co-production between humans and nonhumans. Our research in this study is inspired by and builds upon this related work of human-technology relations.

Study

In this study, we created a print service consisting of four counterfactual printers to investigate the human-technology relationships in digital fabrication. We invited ten experienced makers to choose one of the four counterfactual printers to print models in two rounds. Our study aims to see if it is productive to conceptualize the human-technology relationship in digital fabrication as composite intentionality. Specifically, we ask if this theorized relationship of composite intentionality can produce new descriptive characteristics of the relationship between humans and technology in 3D printing. Given our theoretical approach, composite intentionality (Verbeek, 2008) informed our research aim, the configurations of our printers, and the analysis of our data.

Our overall methodological approach is what is referred to as material speculation (Wakkary et al., 2015). Material speculation is the design of a counterfactual artifact that can be experienced in everyday contexts to ask certain types of research questions. As we discussed in our introduction, a counterfactual artifact is a realized functioning product or system that intentionally contradicts what, given the norms of design and technology, would normally be considered logical to create. This countering of norms opens the possibilities to empirically investigate multiple alternative existences (or what-ifs) as lived-with realities of the counterfactual artifacts. It is important to keep in mind that a counterfactual artifact emphasizes qualities that typically already exist but are buried deep in our norms and routines such that they are often overlooked. This is a form of defamiliariazation that reveals the strange within the familiar (e.g., Braidotti, 2013). The point is that composite intentionality, specifically technological intentionality, is also at work in the most normative settings, like printing with a typically configured 3D printer. Our aim is to bring this out in a more pronounced fashion, call attention to it, and investigate its potential for expanding our understanding of the role of technological machines in making practices.

Our methodological approach combines aspects of typical 3D printing practices, like using a print service—described in the following sections (see Printing Service), with constraints set by research conditions like the number of print sessions and selection of printers. Methodologically, we sought an appropriate strategy given our research questions, and where possible, to extend the approaches of the work of others we detailed earlier (see Related Work). For example, the majority of the related research focuses on the researchers themselves producing the prototypes or prints (e.g., Boucher & Gaver, 2017; Follmer et al., 2010; Mueller et al., 2013; Willis et al., 2010). In participant-based studies like ours, sessions with the digital fabrication tools were typically limited to one or two multi-hour sessions across no more than two days (e.g., Anderson et al., 2017; Devendorf & Ryokai, 2015; Liu et al., 2019; Magrisso et al., 2018) with at most 14 participants (e.g., Devendorf & Ryokai, 2015). Most studies like ours also relied on prior experience and expertise to boot-strap the use and understanding of digital tools. In a few instances, field studies and collaborations with practitioners were employed (e.g., Hammad et al., 2019; Jenkins et al., 2016; Saegusa et al., 2016; Wakkary et al., 2017). We may pursue this approach in future research given the findings of this study. In this context, we saw the length of our study and the degree of involvement in the printing process of our participants as appropriate.

In what follows, we describe our study procedure, the counterfactual printers we configured, the print service that supported the use of the printers, and the participants.

Procedure

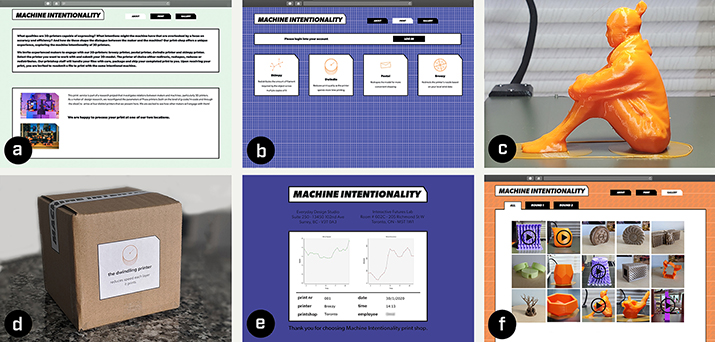

Our study ran for approximately two months with ten experienced makers as participants. Makers interacted with the four printers—we describe in more detail below (see Counterfactual Printers), using our online printing service (Figure 2a). The participants were asked to create a model and upload it to the server while selecting one of our four printers to use (Figure 2b). We aimed for a minimum of two participants per printer on a first come, first served basis. Each maker interacted with their selected printer twice. In the first round, participants uploaded a model of their choice adhering to certain constraints set by us (i.e., 10 × 10 × 10 cm size models with no requirement for support). In the second round of making, makers were free to upload either a modified version of the original model or a completely different model.

Figure 2. Online printing service: (a) website interface outlining the goals of the service, (b) website interface with descriptions of the four printers, (c) example printed model, (d) example shipping package, (e) an example receipt, and (f) print service gallery with pictures and time-lapse videos.

During the study, we interviewed each participant twice and engaged in asynchronous interaction at other times using Facebook, Slack, WhatsApp, and email so participants could share data (such as images of the prints) with us at any time. The first meeting with the participant was done at the start of the study period and was used to describe the study and our research aims and gather some background information about the makers. We gave the participants a walk-through of the online print service interface and introduced the four printers—as described later in the paper (see Counterfactual Printers section). We then conducted a short 30-minute semi-structured interview to learn about how they understood and viewed their relationship with 3D printers. After the participants received their second print, we conducted a final interview. This was a 1-hour long semi-structured interview where we asked about participants’ experiences with our 3D printers, their design rationale and goals, reactions to the received prints, and their perception of how these machines shaped their 3D printing processes. In total, we gathered qualitative data from 15 hours of interviews. It is worth noting that the asynchronous communication channels we made available were primarily and infrequently used to ask logistical or clarification questions that arose during the study. As such, these communications were not included in our data analysis process.

To engage our makers in their making with our counterfactual printers, we created a 3D printing service that we called Machine Intentionality. This service conceptualized printing more explicitly as a technical assemblage and facilitated the process of making our printers available to multiple makers in our study. The process was easily understood as being similar to other online 3D printing services such as Shapeway or i.materialis.

Printing Process

The front end of our printing service was a website (Figure 2a). Each of the makers was given a personal account within which they selected a printer to use for the duration of our study. We explained to each maker how we designed each of the printers [we used Prusa Fused Filament Fabrication (FFF) printers], ranging from altering M-code and G-code to integrating network services to including the requirements of the shipping service for the physical print. Together, these combined elements make up the technological intentionality of each printer. Our aim in being transparent in our actions was to help makers make an informed choice about which printer they wanted to interact with and to avoid the guesswork of how each was configured that would hinder the reflection process on the experience of the print service (Figure 2b).

Once a printer was chosen, the makers could submit their desired 3D models, which then would be printed (Figure 2c) and shipped to the makers (Figure 2d) along with a corresponding receipt (Figure 2e). The receipt contained information about their queue position and printer properties that were associated with their chosen printer. A picture of the final printed file and a time-lapse video documenting the printing of their print was then posted to an online gallery on the website for participants and website visitors to see (Figure 2f). Makers were then invited to submit a second file, either an iteration of their first model or a new file and repeat the previous steps.

Participants

We recruited our participants through a combination of snowballing and targeted recruitment. We reached out to known makers in our communities and advertised information about our study at local makerspaces, institutional fabrication shops, and printer services. The recruitment took place primarily in two different cities but also extended to participants outside of these cities. We aimed to recruit participants who had extensive prior experience with 3D printing, either in an academic or professional capacity, so participants could see past the novelty effects of the printers and relate to them in relation to past experiences with 3D printers. We also looked for a good representation of age, gender identities, ethnicity, and sexual orientation from within these communities. All participant names are pseudonyms. Our participants come from a range of backgrounds, including computer science (Leah, Matty, Adeeb, Debbie), industrial design (Faiz, Quentin, Leah), architecture (Disha), engineering physics (Ezra), and printmaking (Tai), with half of our participants using 3D printers in a professional capacity and half for academic or student projects. Participants had worked with a variety of 3D printers (e.g., Ultimaker, MakerBot, Tinkerine Ditto) and modelling software (e.g., OpenSCAD, Solidworks, Rhino). Our goal was to recruit a minimum of two participants per printer, and we initially surpassed that goal by recruiting 12 participants. However, over the study period, two people discontinued participation, resulting in a total of 10 participants. As a result, two printers were each used by three participants, and two printers were each used by two participants.

In our first interview, we asked for our participants’ perceptions of the role of a typically configured printer, and they all viewed the printer as having an influence on the outcome, albeit passively. All our participants were experienced with (median 4 years of experience; max = 10+ years, min = 1 year) and so they were able to compare their experiences with a typical 3D printer versus our modified printers. For example, Tai submitted a model she used many times before to make the comparison with the printer she chose. Other participants also used prior models or models like prior ones.

We created four distinct printers, each aimed to explore different technological intentionality possible for a 3D printer. It is important to note that our examples are not exhaustive but our rationale for the configurations of each printer was to represent a range of possibilities for technological intentionality. Our printers emphasize different technological intentionalities within a particular range that we describe as reduction, redirection, reshaping, and redistribution. These represent a range of possible configurations of filament flow, nozzle movement, and form-giving. Additionally, we wanted to represent a range of connectivity possibilities for 3D printers. This begins with local technological intentionalities of the print head and filaments such as Dwindle and Skimpy, of internet connectivity as in Breezy, and of socio-technical connectivity as in Postal (see printer descriptions below). Specifically, we altered the local configuration of the printer (fan speed and filament flow), used the network capacities of the printer to connect with data and processing available on a network, and utilized the socio-technical assembly to include the distribution of the prints through mail and delivery services as well as the production of the prints.

Our configurations altered the parameters of the printers at the level of G-code/M-code and through the slicer, to arrive at the four printers:

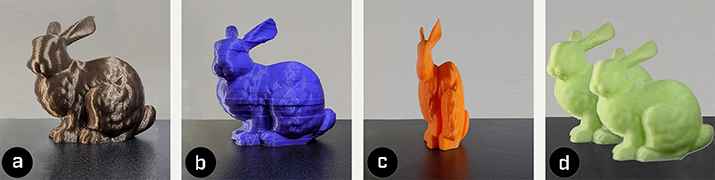

Dwindle: The Dwindle printer increasingly reduces the print quality in relation to how long a given print takes and where it is in the queue of print jobs for that day (Figure 3a). This printer works with two different temporal frames. With each print, the speed and the flow of the machine reduces as the printer continues to print, typically degrading as the printer adds layers to the print. The second temporal frame considers the overall queue of print jobs in a given day of printing. The further down a print job is in the queue, the slower the initial speed and material flow rate is in comparison to the previous print job. The technological intentionality of Dwindle is that its labor and resources like filament are limited in relation to time measured as numbers of jobs and print duration.

Figure 3. Samples of printing outcomes from (a) Dwindle printer, (b) Breezy printer, (c) Postal printer, and (d) Skimpy printer.

Breezy: The Breezy printer redirects the printer nozzle based on the wind data of the maker’s location on the day the maker uploaded the file (Figure 3b). This printer collects the wind’s direction and speed of the selected location for the last 24 hours and maps it into the print by dividing the print into 24 layers and shifting each of these layers by the amount of wind in the direction of the wind. The technological intentionality of Breezy is that its functional boundaries as a printer include the Internet and that it can access any data on the Internet to be used as input parameters.

Postal: The Postal printer reshapes the model for more convenient shipping (Figure 3c). This printer looks at the dimensions of the planned print and decides among three different parcel sizes which one is best for the print. It determines this by finding a shipping package that fits the height of the planned print and then the printer modifies the remaining two dimensions of width and depth in order to conveniently fit the print inside the selected shipping package. The technological intentionality of Postal is that it is part of a large physical and digital system and aspects of the system, like distribution and shipping, create important specifications to complete its tasks.

Skimpy: The Skimpy printer determines the amount of filament required by the 3D model and then redistributes the amount across multiple copies of the model (Figure 3d). This printer calculates the filament density of each object and changes the flow of the print to make better use of the material by redistributing the amount of material it saves in the initial print job to make additional copies. The technological intentionality of Skimpy is that it optimizes the efficient use of its resources like filaments to produce more quantity.

To understand how we modified the printers, we provide a brief overview in an appendix of the numerically controlled programming languages that direct the printer during the printing process (see Appendix 1).

Analysis and Results

We analyzed the audio and video of the two interviews we conducted with each participant for a total of 20 interviews. For the data analysis, we initially utilized inductive coding to iteratively identify patterns and themes. Then, we deductively coded the interview data using concepts from postphenomenology that relate to composite intentionality. Data were coded independently by two of the co-authors, and inter-rater reliability was achieved through discussion and agreement. The analyses were centred on participants’ experiences printing with one of the four counterfactual printers. A total of 20 unique models were designed by our participants and printed by our service (Figures 4-7).

The analytical framework we used to deductively code the data consists of three interrelated postphenomenological concepts (non-neutrality, mutual shaping, shared intentionalities) that form the conceptual building blocks for composite intentionality as per Verbeek (2008). In more detail, we looked for expressions of:

- Non-Neutrality of technology, meaning our participants acknowledged (or not) that they experienced the 3D printers as active contributors to the process and in ways independent of the participants (Rosenberger & Verbeek, 2015). We did not doubt that our configured printers would affect the process, but we were looking to see if participants considered these effects as agentic or noise and errors.

- Mutual Shaping means that participants felt that the print was a product of mutual shaping by both themselves and the printer. This is an adaptation of the idea of co-shaping in postphenomenology in which technologies and humans mutually shape each other in terms of meaning and action (Rosenberger & Verbeek, 2015).

- Shared Intentionalities refer to our analysis of how the sharing or combining of human and technological intentionalities was experienced by the maker. This refers to the very heart of composite intentionality that recognizes the relationship or the necessity to cooperate with technological intentionality (Verbeek, 2008).

The analysis is organized based on the four different pairings of each printer with 2-3 makers and for each pairing, we summarise the analysis based on the concepts above. Before proceeding to our detailed results there is an important commonality shared by all our participants. The makers in our study viewed 3D printers as passive tools that are designed for accuracy and precision, in which imperfections were seen as glitches or errors. In our first interview, participants described printers as a tool, a manufacturer, a tool-in-hand, a fabricator, a mean to an end, and having the duty of faithfully recreating the digital design. With these starting points in mind, participants were open to experimenting and trying out printers in our print service. As described earlier, participants conceptually understood our explanations of what each printer was configured to do but there were still plenty of opportunities for discovery and experimentation.

Dwindle

To remind the reader, Dwindle is a 3D printer configured to increasingly reduce the print quality over time. Depending on how long the given print takes and its position in the printing queue, Dwindle distributes the filament and adjusts its printing speed accordingly. Three participants, Tai, Debbie, and Ivan, printed with Dwindle (Figure 4).

Figure 4. Models uploaded by our participants to Dwindle printer.

Non-Neutrality

All three participants stated they understood our explanation of the printer, yet they were unprepared for the degree to which their prints showed decay and where the degrading quality appeared on their models. Debbie felt that the placements of the decay created an unintentional interactive model. According to Debbie, the degrading allowed for unexpected brittle textures, sounds, and other multi-sensory experiences to emerge, adding a sense of playfulness to the model. Tai, meanwhile, was clear that decay is not typically what you’re going for in digital fabrication and further with Dwindle, the degree of decay was unpredictable as the second model came back with very little decay compared to the first model. Despite saying he understood the design of the printer, Ivan continued to create a model that required precision and accuracy and so he lamented the poor quality of the prints. Tai, Ivan, and Debbie saw Dwindle as serendipitous or that there was a trick within the printer that they could not out-trick or unlock so to speak. Ivan described the printer as having a personality, being humanized, and having its own autonomy, while Debbie described it as an entity that could modify what the output is or like your mother trying to anticipate and look out for you. From these descriptions, it seems clear that while only partially intelligible, Dwindle was seen to be non-neutral, independently and actively contributing to the process.

Mutual Shaping

In experiencing a more active role by Dwindle, Debbie, and Tai showed openness in working with its properties. In the first round of printing, participants selected models that were familiar to them or that they had printed before with a typical 3D printer. For Debbie, round one’s model was a rolling pin with different patterns to function as a texture stamper for clay. Tai submitted a previously designed print she called a maker cookie and Ivan designed a flying cat model (Figure 4). Based on the perceived qualities of Dwindle, the models evolved from being somewhat functional to having an exploratory characteristic in round two. In response to round one, Tai attempted to take the decay in the design in the second model to understand the possibilities and limitations of the printer and therefore take advantage of it. Debbie wanted to game the printer and its properties as well as exaggerate what it could do, and so Debbie re-designed the second model such that the unintentional interactive qualities from the first print were deliberately applied in the second model. Unlike Tai and Debbie, Ivan attempted to fix the decaying problem by using the same model for the second round and only changing its orientation on the print bed (Figure 4). From these descriptions, we determined that participants felt that their prints were a product of mutual shaping by both themselves and Dwindle.

Shared Intentionalities

Debbie and Tai felt they understood the technological intentionality of Dwindle as we had explained it, while it became clear that Ivan, in many ways, treated Dwindle like any other 3D printer. Nevertheless, all three participants recognized Dwindle’s creative potential. Surprisingly, despite Ivan’s skepticism or reluctance to see an active role for the printer, he would go on to say that Dwindle was like a robot, that I can talk to it, and that the relationship feels like a collaboration. Tai also expressed how the collaborative role of the printer can be experienced as the printer having a hand in the final result and how the maker yields to losing control. However, the makers wished these types of modifiers, which almost always happen by accident, could be adjusted to match the degree of the makers’ openness to inspiration, serendipity, and artistic expression or having fun.

For Debbie, the intentionality of the printer “is a piece in-between, where it is not the actual printer itself making the changes, but some intermediary software or a script that is changing the model.” This explanation was an interpretation that unpacked the technical assemblage within the conceptualized printer and layers of structured intentionality. Debbie explained how a mediator is employed between the maker and the printer such that, in this process, the maker determines the “first-level modification of the model and then that gets sent to a second-level modification [the script or the software], and that is what actually goes to the printer.” According to Debbie, the modifying level, which is a separate component in this collaboration, can determine the finishing details.

Breezy

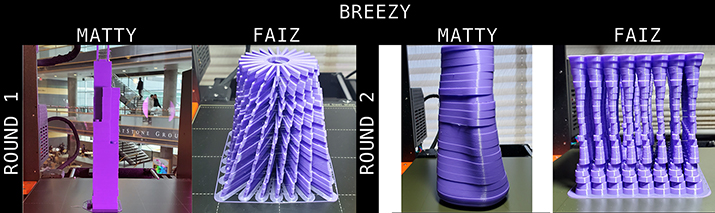

To remind the reader, Breezy is a 3D printer that is configured to redirect the printer’s nozzle based on the local wind data of where the model was made or the location of our makers. Two participants, Matty and Faiz, printed with Breezy (Figure 5).

Figure 5. Models uploaded by our participants to Breezy printer.

Non-Neutrality

Like Dwindle, participants thought they understood Breezy based on our explanations but were unprepared for the magnitude and type of effect. For the first print, Matty expected the wind to have a greater effect and didn’t realize it would be so blocky and robotic. Rather, he expected the shape to be a lot more organic. Meanwhile, Faiz claimed to mentally envision what would happen but could not fully anticipate the extent of what would happen and so was surprised at the level of detail of the stepped and chunked effect of the print and at what location or orientation the shift would take place.

Breezy was seen to hold knowledge discretely separate from the makers. Both Matty and Faiz did not know what wind data would be used for the print, whereas the Breezy printer did. Based on this, Matty described Breezy as a black box on two occasions and as having a personality and a funky attitude. Further, Faiz indicated that Breezy was able to infuse that data into the objects and that the object carries a lot more context than perhaps the participants were aware of. Here again, the makers unpacked specific aspects of the technical assemblage of the printer as having more effect or non-neutrality.

Mutual Shaping

Inspired by the Windy City and wanting to assess the printer based on a simple shape, Matty selected for the first round, a model of the Willis Tower in Chicago. Meanwhile, Faiz designed a tapered finned-heatsink structure that was to be open-ended and a blank canvas (Figure 5). He assumed that it would print smoothly and delicately. Based on the results of the first round, Matty remarked, “I know how this is doing it” and “I can see what it did here, here, [and] here.” Meanwhile, Faiz claimed to “understand exactly what was going to happen on the second print.” Based on this new understanding, both participants designed different files for the second round. Matty wanted to create a funky, cool, organic shape, so he designed a structure of stacked potato-like shapes of varying heights to generate an organic curve and to see the differences between the two models. Faiz designed a columned-skyscraper structure that maxed out the 10 × 10 centimeter print area with more robust geometry and tactility “to see, kind of, how far I could push it” (Figure 5). What became clear is that Matty and Faiz both saw the need to anticipate the actions of Breezy in shaping the outcome. In this way, the mutual shaping with Breezy was like a dance or sparring partner that could involve testing of each other’s abilities and limits.

Shared Intentionalities

While participants described Breezy as a black box, having a personality and a funky attitude, and the relationship as back-and-forth and a dialogue between the maker and the machine, they resisted attributing any level of sentience, consciousness, or agency to Breezy. Yet they were willing to pull apart the black box of the printer as an assemblage of software and hardware. Citing John Searle’s Chinese Room thought experiment (Cole, 2020), Matty asserts that printers like Breezy are excellent rule followers. In that way, Matty found that Breezy was super easy to reverse engineer. Further, when asked, Matty agreed that he debugged the model while Faiz similarly agreed that he decoded it. Given that both Matty and Faiz are technically proficient participants, they felt the way to control Breezy was through unpacking the technical assemblage of the printer. With that in mind, Faiz remarked that “surprise and manipulation is so far removed from the expectation of what a 3D printer is going to give you” and that they “can’t think of a realistic application of design that needs to be manipulated this way.”

However, Matty and Faiz both perceived creative potential for 3D printers like Breezy. According to Matty, printers with personalities can be used as a tool for creativity, to generate a lot of ideas, and to explore and create different things. Faiz suggested that a printer like Breezy is suitable for a sculptural or artistic practice. Further, both Matty and Faiz conceived of possible scenarios of use for printers like Breezy. Faiz suggested printing varieties of clouds or graphs based on wind data and scenarios where dozens of 3D printers are distributed with wacky intentionalities that are only discoverable through use. Finally, Matty suggested a pedagogical use case by giving 3D printers to elementary school kids with the option for four or five personalities like Breezy. While both Matty and Faiz demonstrated resistance to the technological agency in the two rounds of printing, they could anticipate more open and collaborative possibilities for future use.

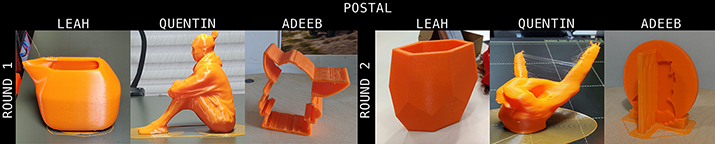

Postal

To remind the readers, Postal is a 3D printer that is configured to reshape the model for more convenient shipping. Three participants, Leah, Quentin, and Adeeb, printed with Postal (Figure 6).

Figure 6. Models uploaded by our participants to Postal printer.

Non-Neutrality

Unsurprisingly, participants clearly experienced how Postal changed the size and proportions of the models in the printed outputs but did not expect the extent of the change. Leah did not expect the degree to which both the prints were sized and squished. Quentin was surprised at how little [Postal] distorted the first print but was also surprised at how much more [the second print] seemed to have distorted, flattened, and skewed. Adeeb, meanwhile, seeing that the first print came back one inch tall and the second print was re-oriented, remarked, “Oh, you tricky printer, I didn’t expect that.”

Given the obvious interventions of the printer, Leah said Postal “had a mind of its own,” was almost conscious, and was both clownish and a very simple childlike creature. According to Quentin, “it really doesn’t care what it is you’re putting into it,” and Postal doesn’t even match the longest side with the longest side of the box. Further, Adeeb noted that “the printer’s role was to screw with me” and likened the printer to an AI agent. Postal was seen as non-neutral and having an agentic role in the process. However, similar to comments by our other participants, the relationship with the printer is by no means seamless or transparent and can even be antagonistic.

Mutual Shaping

Leah, Quentin, and Adeeb expressed difficulty in anticipating the size, scale, orientation, and appearance of their prints. For the first round, Leah designed a functioning watering can. Whereas the first print for Quentin was a model of a posed friend in a way that would present well as a print, and Adeeb designed a non-functional Baby Yoda cookie cutter to fit within the bounding box and gain an understanding of the printer’s volume parameters (Figure 6). Based on the first round, each participant submitted a different CAD file for the second round to adapt to the actions of the printer. For the second print, Leah submitted a flowerpot to fit in the maximum dimension, so I could see how much it would squish. Quentin determined to be more deliberately loose with their second print and submitted a human hand in the horns gesture to see how the printer would orient the print. Finally, Adeeb decided to trick the printer and designed a coaster in such a way that it would prevent the printer from scaling it (Figure 6). As such, participants designed their second prints to either maximize, minimize, or manipulate the printer’s parameters. In this respect, like participants who experienced Dwindle and Breezy, Leah, Quentin, and Adeeb were also focused on understanding the effects of Postal on their prints. Postal was seen to be active in shaping the outcome, yet in ways that required exploration.

Shared Intentionalities

Like Debbie, based on the collective experience with 3D printers and programming, Leah, Quentin, and Adeeb sought to locate the cause of Postal’s behavior within the software and other mediating layers in the print service. For example, Leah noted that “I know that it was programmed to do this and this.” According to Quentin, this is a “funny intermediary step that I would say [the intent] was largely like, with [the researchers]” in “how the model is positioned.” Similarly, Adeeb speculated about a mediator in the middle, expecting there may have been someone preparing the print file, a software-based algorithm, or some type of artificial intelligence.

At the conclusion of the two rounds of printing, Leah, Quentin, and Adeeb admitted to not really understanding the technological intentionality of Postal. Further, Quentin described printing with Postal as a process of developing a relationship, I guess, with the machine, Leah described the process as requiring a bit of back and forth, Leah and Adeeb both called it a dialogue, while Adeeb referred to this collaboration as a fight. Leah expressed that it is difficult to anticipate the effects and outputs of Postal, and after both prints, Quentin commented, “Oh no, I don’t understand.” Finally, Adeeb wanted to submit more prints to better understand the algorithm and referred to Postal as a black box. To this end, as expected, Leah and Adeeb determined that the Postal printer was not useful for the needs typically met by a conventional 3D printer. According to Adeeb, “I don’t always want some unexpected result,” and Leah likened Postal to a printer at the cheaper end of the line. However, while saying they did not understand the machine, each participant observed the creative potential of Postal. In anticipating new use cases and opportunities, Leah stated that 3D printers like Postal are suitable for an art piece. In anticipating future prints, Quentin expressed willingness to riff on that a little bit more, to make the most distortion and the most weirdness I could possibly get out of it, and really screw with it. Additionally, Adeeb indicated that anticipating the printer would reshape the file in some unexpected way caused them to think more creatively, critically, and freely. Further, given the desire of Leah for practicality and utility, they added that it is also the personal responsibility of the maker or user to find creative uses for these outputs, noting that it “forces you to be creative and try to make something out of what you get” and “I’d have to repurpose the object to find a new function for it.” While the sense of not understanding a printer is unfamiliar to participants, they seemed open to experimenting more or collaborating with a printer with properties like Postal.

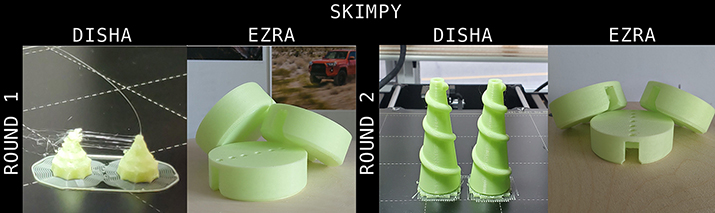

Skimpy

To remind the reader, Skimpy is a 3D printer configured to redistribute the amount of filament across multiple copies of the model. Two participants, Disha and Ezra, printed with Skimpy (see Figure 7).

Figure 7. Models uploaded by our participants to Skimpy printer.

Non-Neutrality

Yet again, the effects of the prints were not something the participants had fully anticipated. For the first print, Disha did not realize how many and how small and tiny her prints would be to the point that some broke. Both Ezra and Disha found that Skimpy printed very light prints. However, after some adjustments to the model by Ezra, the second print did not break as it had in the first round. Disha was pleased that the prints were heavier, even more so than she expected. However, despite the printer producing round two models that were considered an improvement to round one, Disha and Ezra did not see the non-neutrality of Skimpy as significant. Rather, it was seen more as a deficient printer with odd outcomes.

Mutual Shaping

Given the way in which Skimpy was perceived to affect the process, participants felt the printer’s technological intentionality was something that could be worked around. Disha responded to the first print, which was an earring, by changing the earrings’ design and increasing the size of the model (Figure 7). Ezra used the same design in both rounds but enhanced the strength of the model by adding extra beams to the base, given that all printed parts broke in the first round (Figure 7). Ezra claimed that “by the second round, I knew exactly what the printer was doing” and therefore anticipated what the print would be like. Through the alternative design, Ezra could figure out a way to work around the weight distribution without adding more weight to compensate for the reduction.

Shared Intentionalities

Despite Skimpy having less of an effect on the process, Disha and Ezra identified Skimpy as both practical and having creative potential in ways it could collaborate with the maker. Disha described how Skimpy could potentially be utilized as a partner having an agency without compromising the designer. According to Disha, Skimpy could, in fact, be beneficial to jewelry designers, considering the printer has an algorithm that can reduce the weight of what you design which would account for the weight the person has to carry while wearing the jewelry. Disha added that with the properties of Skimpy, a human-technology collaboration would emerge such that “You didn’t only design it [the printed model], a machine designed it with you.” Ezra identified 3D printers, and tools in general, as having intentionality built into them and that Skimpy had these intentionalities amplified. Ezra described how “if you look at the 3D printer as a tool, you would want it to be very consistent” so you can “intuitively invite it into your workflow.” In this case, “you don’t want them to have their own additional attributes on top of the manufacturing attributes.” However, Ezra pictured a scenario where Skimpy could be used as a medium of expression as an artist would approach it. In this example, the dynamics would significantly change such that “you could think of it [the printer] as a type of brush for expression.” In considering Skimpy’s contribution to the fabrication process, both Disha and Ezra describe a role that augments their actions passively in collaboration and more as matters of delegation.

Characteristics of Composite Intentionality of Makers and 3D Printers

In this study, we set out to see if theorizing the combination of the maker and 3D printer as composite intentionality could yield characteristics of the human and nonhuman relationship; and help us better understand the role of digital fabrication technology. In this respect, the important basis of our findings is that the composite intentionality of our 3D printers and participants jointly shaped the outcomes of the prints and affected the planning and design of the models by the makers. For these findings, it was not necessary for the makers to fully understand, accept or validate the notion of composite intentionality; rather, we used the concept as a lens to frame the relationship and analyze the process of making.

Our findings surfaced the following characteristics: a) opening a space for anticipation that accepts a role for the technological machine in shaping the outcome in surprising ways; b) that the relationship with the technology is one of itineration, a co-exploration of where the creative process can go; and c) there is resistance to the idea of technological intentionality at work in digital fabrication, which at times can be productive. We further found that the printers were readily seen as technical assemblages, and so an additional finding is that technological intentionality could be unpacked as layers of technological intentionality.

Anticipation

The first characteristic we discuss is what we refer to as anticipation. We see this as a key characteristic in the dynamic between the makers and our printers in our study. We refer to the notion of anticipation less in the sense of prediction and more in the sense of probability or expectation, with the acceptance of being surprised or not knowing the full extent or details of future actions (as expressed by all our participants). For example, Matty compared his experience with the Breezy printer to baking. Baking is a process highly affected by nonhuman agents of yeast, humidity, and temperature that are hard to control precisely. So a baker yields an anticipatory space of action. Our participants often described that space as a dialogue with the printer, in which, like all conversations, one listens with anticipation and degrees of willingness to be surprised, to learn something new, or even to be transformed.

When thinking of anticipating the role and actions of technology, there are similarities to collaborations between people that can be described as engaging, disappointing, humbling, antagonistic, experimental, frustrating, and surprising. In many respects, a characteristic like anticipation partially exists in current practices with technologies. However, our findings show that we can greatly expand this anticipatory space to allow for a greater role for technologies like the space we give to other humans in collaborative endeavors. And further, anticipating the unique technological intentionality of a nonhuman collaboration is seen as a positive. For example, Faiz anticipated that Breezy would capture wind data, and he was open to the surprise that this would create. For Faiz, anticipation was to mentally envision what would happen but be willing to not know the extent of what would happen.

In the context of postphenomenology, anticipation is a key term in describing the need to anticipate the mediation of technology in how we act and think in ways that are resolute and focused, a self-practice in determining who we are in this world (Verbeek, 2011). The same self-practice can be applied to composite intentionality by a willingness to anticipate and experiment with creating more space for the agentic contributions of technology. In this sense, within composite intentionality, the anticipation of the actions and effects of the technology, independent of our human aims, takes on greater importance and can even be seen as a positive addition to the process.

Itineration

An itinerant is one who travels from place to place. This describes well the back-and-forth of the composite intentionality of maker and printer that leads the process from one place to another. For example, Postal shifted Leah from seeing the relationship as a matter of utility to her saying that the printer “forces you to be creative and try to make something out of what you get.” For Debbie, Dwindle transformed her model into being playful, which was not her original intention. Yet, she decided to go there with Dwindle and exaggerate the playfulness in her second model. The well-used metaphor of the creative process as a journey is apt in this combination of different intentionalities between humans and nonhumans that move the process from one place to another.

The printers can be said to be fellow travelers that required developing a relationship with, according to Quentin. Seeing composite intentionality as itinerant gives technologies qualities of agency that led our participants to refer to the printers as a partner, childlike creature, a mother on the lookout for you, and to have a mind of its own. These metaphors speak to the independent shaping of the process of the printers and how, as co-travelers, they help to shape and delineate the anticipatory space of action we described above.

Lastly, this characteristic of technology as an itinerant in a creative or craft process resonates with what Tim Ingold sees as the itinerant nature of tools and materials. Ingold describes sawing a plank of wood as an itineration in which there is a complex action of the carpenter following the material of the wooden plank in reaction to the saw blade. For Ingold (2011), in this collaboration, “no two strokes are quite alike” as the carpenter is “obliged to follow the material and respond to its singularities” (p. 216). Ingold contrasts his idea of itineration, the co-traveling of materials, tools, and humans in unique ways, with “iteration,” which he sees as passive materials and tools put to a job of repetitive tasks.

Resistance

To describe the last characteristic, we use the term resistance to refer to responding to the differences within composite intentionality. Resistance is unique in relation to the other characteristics in that it is a dynamic that cuts across anticipation and itineration signaling there is a space of difference between what is anticipated and what occurs or differences in the directions of itineration between technologies and humans. This characteristic underscores that a degree of harmony is important in composite intentionality, but degrees of difference and productive tensions are also important.

The study data clearly shows that the collaborations between our printers and makers resulted in friction that could be described at times as antagonistic or competitive. At its most explicit, the relationship was described as a fight. This type of resistance is unsurprising if we assume there was a degree of getting used to the greater presence of the printers in the process. However, looking deeper, this type of resistance also formulated itself as creative strategies such as the idea of gaming or tricking the printer, in which there is a competition to outwit the other in terms of shaping the final outcome. Metaphorically, shared creativity emerges between sparring partners in boxing or martial arts. We can also see resistance in the less antagonistic sense in that the composite intentionality was described as a partnership or riffing with like a dance partner that you can playfully engage with or, at times, literally use the physical resistance of the partner to support a dance move. This resistance within the composite intentionality of this study is productive and signals that neither printer nor maker is wholly subordinate and neither has full autonomy.

Richard Sennett, whose views on traditional craftsmanship have informed digital and human-computer interaction understandings of craft (Frankjær & Dalsgaard, 2018; Hummels & Trotto, 2014), explains how resistance created by tools can arouse the imagination and open new creative possibilities (Sennett, 2008). He explains that when a tool breaks free from its fit-for-purpose aims—such as with our 3D printers—there can be productive forms of resistance that include new processes that seek paths of less resistance; or the capacity to stay with the frustration creates patience in a craftsperson that holds value in the long-term; and lastly, a craftsperson can identify with the resistance, the challenging tool, in ways that open new nonhuman perspectives within the crafting process. These ideas resonate with our findings; however, we describe a combined agency or autonomy that goes beyond the increased awareness of the craftsperson. This shared autonomy through differences and kinship rather than hierarchy echoes what Donna Haraway (2016) calls response-ability, in which one both listens and acts in a collective fashion of talking and listening, thinking and observing with others (humans and nonhumans) to cultivate the capacity for responses in ways that are collaborative within unexpected worlds.

Technology as Assemblage and Layered Intentionality

We also want to highlight the ways our participants conceptualized the technological intentionality of the printers and print service or unpacked the respective printers. It is fair to say that in most postphenomenological accounts of technological intentionality, the technology or technological artifact is described as a phenomenological whole, in which intentionality arises from the embodied relationality of all the parts, i.e., hardware, software, programmers, networks, etc. Further, each of the parts is not seen in isolation nor singled out from the agentic force of the overall whole (Verbeek, 2008). However, it is clear from our study that our participants described technological intentionality more as an assemblage of technologies rather than a singular whole, and specific to our interests, intentionality was seen as layered within the assemblage. The participants unpacked the technical assemblage as a series of mediating layers described as a diverse range of agents, including software, AI algorithms, programmers, us as the researchers, and behind-the-scenes manual operators. The source of intentionality was human, nonhuman, or combined agents that functioned as a mediator or intermediary within the assemblage.

This unpacking of the assemblage should be seen against the backdrop of participants having a range of understandings of the printers, from being a black box on one end to being super easy to reverse engineer on the opposite end. Further, the conceptual models for understanding intentionality in this context ranged from assigning causality to different effects, e.g., the researchers altered the digital models to less deterministic outcomes of software programming or the effects of external sensing data. Our findings pull together these experiences into a model of technical assemblage that the participants did not explicitly articulate. Yet, the phenomenological whole of the printer (seen as a concrete technological artifact) was not typically assumed, or it was questioned and added to the traditional postphenomenological understanding of technology.

Discussion

Our findings detail the characteristics of anticipation, itineration, resistance, and the technology as an assemblage that helps describe the human-technology collaboration between our print service and the makers. The characteristics and descriptions add to findings in related research that see technologies like 3D printers as collaborators. For example, the characteristics as a whole add a further layer of understanding to the porous interplay between humans and technologies when skills and actions are shared (Kim et al., 2017) and the agency is bidirectional (Kim, 2017). Sennett (2008) sees this two-way interplay with tools as a matter of ambiguity that leads to productive improvisations and so should be befriended. In doing so, he describes the relations between craftsperson and tool as dynamic.

Our findings offer more concrete language for understanding this dynamic. More specifically, anticipation offers a perspective on how trust with technologies can be negotiated (Devendorf & Ryokai, 2015); and itineration specifies the performative relations of co-production and multiplicity (Devendorf & Ryokai, 2015; Saegusa et al., 2016); and lastly, resistance makes material the ongoing dynamics of control and agency that underlie much of the research in this area (e.g., Devendorf & Rosner, 2017; Devendorf & Ryokai, 2015; Jenkins et al., 2016; Leahu, 2016). The contribution of our study is to offer theoretically and empirically derived characteristics of the composite intentionality of the maker and digital fabrication technology. Further, we describe technologies as an assemblage of technologies and humans, all with different intentionalities. We would argue that these contributions suggest the potential to expand the space of collaboration and the role within that space of technological machines.

At the outset of this article, we cited how descriptions of the role of technologies have not changed, despite the evolving characterizations of people who use technology as crafters, tinkerers, and makers (Roedl et al., 2015). We argued that this view obscures aspects like technological intentionality that are characteristic of all technologies. Our contribution is that by theorizing the relationship between maker and technology as composite intentionality, we better describe the obscured reality of the role of technologies in digital fabrication but also offer characteristics that can contribute to creating a more expansive space and role for technologies in the creative process. Like Giertz’s (2020) shitty robots, Devendorf and Ryokai’s (2015) Re-Deform/Being the Machine, and our own print service, we playfully challenge the idea that creative technologies are exclusively functional or reliable.

A clear question arises from our findings: what would it mean to transform the technologies and practices to expand the anticipatory space of co-created outcomes or add to the itinerant possibilities of where creative processes and outcomes may travel?