Affordances as Materials Potential: What Design Can Do for Materials Development

Bahareh Barati 1,* and Elvin Karana 1,2

1 Department of Design Engineering, Delft University of Technology, Delft, Netherlands

2 Centre of Applied Research for Art, Design and Technology, Avans University of Applied Sciences, Breda, Netherlands

Given the growing interest in “upstream” collaborative projects between designers and materials scientists, it is crucial to scrutinize designers’ creative contribution to materials development beyond “coming up with” application ideas. Overcoming this outdated preconception requires a shift away from the dominant perspective of cognitive psychology that understands creativity as being in the designer’s mind, to an understanding of it as being distributed between the designer and the material world. Creativity as such requires designers’ active participation in “discovering” the novel potentials of materials rather than merely translating the “given” materials information to product applications. In this paper we propose the materials potential framework to liberate materials from the stigma of a purely solutionist approach (e.g., materials selection and application potential), and open up the possibility to approach materials generatively, for all they have to offer (i.e., materials potential). To that aim, our paper explores existing notions in the discussions of materials potential, namely form, function, and experience as materials potential, and provides a conceptualization beyond the evident merits of product applications. The conceptualization of “affordances as material potentials” shifts the focus to designers’ skillful acts of making and fabricating as ways of unlocking novel affordances of conventional and emerging materials.

Keywords – Materials Potential, Affordance, Materials Experience, Material-Driven Design, Materials Development.

Relevance to Design Practice – Arguing how novel affordances, as materials potential, are unlocked through the act of making, this paper emphasizes the limitations of existing product-oriented concepts in discussing designers’ creative contribution to materials development. It advocates an organizational structure wherein designers become equal partners in “exploring” such potentials through early materials engagement.

Citation: Barati, B., & Karana, E. (2019). Affordances as materials potential: What design can do for materials development. International Journal of Design, 13(3), 105-123.

Received July 26, 2018; Accepted November 6, 2019; Published December 31, 2019.

Copyright: © 2019 Barati & Karana. Copyright for this article is retained by the authors, with first publication rights granted to the International Journal of Design. All journal content, except where otherwise noted, is licensed under a Creative Commons Attribution-NonCommercial-NoDerivs 2.5 License. By virtue of their appearance in this open-access journal, articles are free to use, with proper attribution, in educational and other non-commercial settings.

*Corresponding Author: b.barati@tudelft.nl

Bahareh Barati is a postdoctoral design researcher in the Faculty of Industrial Design Engineering at Delft University of Technology. Bahareh received her MSc (cum laude) in Integrated Product Design from Delft University of Technology and was named Best Graduate of the Faculty of Industrial Design Engineering in 2012. She received her PhD in 2019 from Delft University of Technology. In her PhD work she developed strategies, tools and exemplars to unpack the potentials of light-emitting materials, and disseminated her work at design and ACM conferences such as CHI, in international journals, and at exhibitions such as Dutch Design Week. Her current research and educational activities bring into focus the unique qualities of smart and biological materials in designing and prototyping performative and adaptive products.

Elvin Karana is Associate Professor in the Faculty of Industrial Design Engineering at Delft University of Technology, where she founded and directs the Materials Experience Lab. Giving emphasis to materials’ role in design as experiential and yet deeply rooted in their inherent properties, Elvin explores and navigates the productive shifts between materials science and design for new materials development. In 2019, she founded Material Incubator, a creative research lab that aims at designing materials that incorporate living organisms, and exploring their potential in fostering an alternative notion of the everyday. Material Incubator brings together researchers and practitioners from Avans University of Applied Sciences, Delft University of Technology and Willem de Kooning Art Academy.

Introduction

Parallel to the growing interest in “upstream” collaborative projects between designers and materials scientists (e.g., EU projects such as LTM, BioX, Damadei, and Trash2Cash), researchers have pondered on what designers could do for materials development (e.g., Nathan et al., 2012). Referred to as “creativity/design-driven” materials development, these projects make explicit reference to the creative contributions expected from designers, for example by assisting in the development of prototypes to illustrate possible application areas, or by bringing the perspectives of consumers to materials research. But how can designers contribute to such projects if the state of development of a material is still far from the stage of being commercialized? Is their creative contribution only about “generating product ideas” for these new, yet “underdeveloped,” materials? Or does it go beyond that?

Many researchers and practitioners have argued that designers can bring to light a different, possibly more encompassing, understanding of the potentials of a new material (e.g., Nathan et al., 2012; Miodownik, 2007; Lefteri, 2006; Colette, 2017; Montalti, 2017; Nimkulrat, 2009). Traditionally in materials and design, materials potential is framed as the application potential of materials, following the triad of fabrication (i.e., preparation of materials for initial use), application (i.e., transformation of materials into products), and appreciation (i.e., reception of materials by the entire community of users) (Doordan, 2003). This conceptualization falls short of specifying the creative contributions of many designers who are involved in material(-driven) design practices, e.g., DIY materials (Rognoli, Bianchini, Maffei, & Karana, 2015). These emerging design practices at the intersection of design, materials science, biology, arts, and crafts have radically changed the role of the designer from a “passive recipient” to an “active maker” of materials (Rognoli et al., 2015; Myers & Antonelli, 2012; Ribul, 2013). In these practices, the material “elicits and actualizes” (designers’) intentionality. The “mediational potential” of the material (Malafouris, 2008), identified by “situational affordances” (Gibson, 1979; Knappett, 2004, 2005) and discovered through skilled action (Ingold, 2013), shapes the nature of the designer’s intentions (Malafouris, 2008) and creative action (Glăveanu, 2014). Studying these skillful material practices has contributed to more recent theories of creativity, namely embodied creativity (Stanciu, 2015) and distributed creativity (Glăveanu, 2016), looking into the intimate interplay between the mind, the body, and the environment in the unfolding of human creativity (Rietveld & Kiverstein, 2014). However, these relatively recent scientific endeavors are still in their infancy (Stanciu, 2015), and are therefore far from being embedded in design research and in the organization of collaborative projects in which designers are expected to make a creative contribution.

As we turn our attention to how creative contribution, or creativity, is understood in design, we notice that most cognitive theories regarding idea and concept generation (e.g., divergent, analogical and associative thinking) hardly scratch the surface of the complexity of such creative practices (Malafouris, 2008; Glăveanu, 2014). They have explained how “problem framing” (Schon, 1983), coevolution of problem and solution pairs, and interpreting and bridging the information in a brief, for example, are important in supporting a “creative event” (Dorst & Cross, 2001). Viewing design as a “problem-solving” activity has led researchers to assess design creativity based on generated outcomes that are novel and efficient (or appropriate) in resolving “problems.” But perhaps the concept of problem-solving “leaves too much out that are of real significance” (Malafouris, 2008, p. 32) in understanding how material potentials are discovered and exploited in material(-driven) design practices. Being inclined to theories of problem-solving that consider the phenomenological compound of brain, body and resource (see Hutchins, 1995; Kirsh,1996), many design researchers have elaborated on how the social context of designing and external (visual and informational) stimuli (e.g., Howard, Culley, & Dekoninck, 2010) may influence designers’ creative performance. These embodied and distributed views, however, have not challenged the established treatments of “idea generation” as the main focus of creativity studies in the field of design research (e.g., Chulvi, González-Cruz, Mulet, & Aguilar-Zambrano, 2013; Sarkar & Chakrabarti, 2011).

A disconnection between emerging material practices and the prevalent understanding of creativity in design can have consequences for the proposed methodologies or organizational structures of such collaborative projects, and the achieved outcomes. For instance, designers might be expected to understand new (and possibly yet-underdeveloped) materials and their potentials and conceptualize applications, while their access to the new materials is kept indirect and mediated (e.g., through information and schematics) (Barati, Karana, & Hekkert, 2019). Or the project might be organized in such a way that designers end up “framing” and “rendering” with their “imaginative minds” what others (e.g., materials scientists, engineers) have already assumed to be the material potentials (cf. Ingold, 2012). There is no problem with such a one-way dialogue, as long as the “guest” designers are clearly briefed and commissioned, rather than referring to the project as creativity-driven materials development.

We strongly believe that designers should be equal partners in projects where “creativity-driven materials development” is considered as the core merit. This requires designers’ active participation in “discovering” the novel potentials of a material rather than merely translating “given” materials information to product applications. To that aim, we need to revise our understanding of design practice as an evolving interdisciplinary material practice, corresponding to recent developments in the field, and work with creativity theories that embrace and reflect such embodied and distributed accounts of design creativity. To take a theoretical step towards supporting such equity in upstream collaborative projects, our paper explores existing notions in discussions of material potentials and provides a conceptualization beyond the evident merits of (proposed) product applications. Drawing on recent work in the emerging fields of embodied and distributed creativity (e.g., Rietveld & Kiverstein, 2014; Glăveanu, 2014; Malafouris, 2014), we introduce and elaborate on “affordances as material potentials.”

A framework of materials potential is presented to provide an expanded vocabulary for specifying and discussing designers’ creative contributions to materials development. To that aim, the paper revises prominent concepts (form, function, and experience) for the understanding of materials potential in the materials-related design literature to date. It expands on this conceptualization by shifting the focus to designers’ skillful acts in materials engagement and discusses how novel affordances, as materials potential, are “perceived,” “invented,” and “exploited” through the act of making (Glăveanu, 2012). We present a number of design cases from our own and others’ creative material-driven design practices to illustrate how these theoretical concepts may apply.

Materials and Creativity Crossovers in Design

The aim of this background section is to provide an overview of developments in the field of design research at the crossroads of materials and creativity, since the Bauhaus.

The Bauhaus (1919–1933) had a profound influence on the development of the design field, particularly in establishing a pedagogical and pragmatic approach to materials understanding and creativity (Vernon & Sullivan, 2007). The faculty and students at the Bauhaus were the first to combine the knowhow of traditional craftsmanship with contemporary machine processes, and to create a unified style that brought together art, craft and technology. Bauhaus instructors were keen advocates of learning about/with materials through sensory encounters and hands-on exploration (Bayer, 1975). Their educational approach reflected the intimate connection between direct experiences of materials, and learning about their essential and diverse characteristics. The hands-on approach was indispensable to the central principle of “truth to materials,” which favored forms and expressions that were “honest” to the “nature” of the material. The Bauhaus promoted the use of unorthodox materials (e.g., tubular steel) and leveraged their design potentials in constructing items of furniture that are now considered design classics (e.g., cantilever chair by Marcel Breuer).

The first-year workshops (Vorkurs) with different materials at the Bauhaus were a means to liberate the student “from the dead weight of conventions” (Gropius, 1935/1965, p. 71). Here, creativity lies in transgressing such norms and is directly linked to the visual and tactile experience and practical application of materials and forms that emerge from a process of manufacture (Franciscono, 1971, Walter Gropius and the Creation of the Bauhaus in Weimar, as cited in Mindrup, 2014). The “Bauhaus idea,” as argued by Moholy-Nagy (1947), was to delve into a given medium in order to extract the key properties of its structure and translate them into “productive principles” (Mindrup, 2014). He remarked, for instance, how the processes of cutting and sawing made a rigid board “rubber-like,” irrespective of whether the board was made of cardboard, plywood or metal.

Many designers in the history of design followed a similar approach and constructed products by direct exploration and manipulation of materials and their diverse shapes, textures and finishing possibilities. Contemporary examples include Paulo Ulian (marble), Tokujin Yoshioka (paper, glass), and Piet Hein Eek (scrap wood). However, as the complexity of design projects and problems escalated, materials knowledge and expertise became increasingly distributed among designers, engineers, materials suppliers, and manufacturers, giving rise to a need for efficiently exchanging the “key” materials information.

Designers as “problem solvers” and “visionaries” needed efficient ways of realizing their solutions by selecting the “right” material from a large pool of commercial materials that were largely developed by scientists and engineers. The elaboration of “materials selection” models and tools in the design literature mirrors this established need of design practice, closely linked to functional design. The scientific understanding of materials, made possible by probing and measuring their structures and properties, allowed designers to treat materials as bundles of properties (Ashby, 1999). As Ashby explains, it is not a material per se that the designer seeks; it is a specific combination of process and material attributes. This scientific/engineering perspective to materials provided solutions to the complexity of finding optimum matches to predefined design intentions and requirements. Thus, instead of trying each and every material directly, digital databases and property profiles enabled designers to compare the technical performance of the materials and reduce their choices to a handful. Today there are numerous tools specifically developed to assist product designers and engineers in their material decisions (for a review of the digital tools for materials selection see Ramalhete, Senos, & Aguiar, 2010), including general databases (e.g., Cambridge Engineering Selector [CES] by Granta) and manufacturer databases (e.g., Sensotact® by Renault, described in Allione, Buiatti, De Giorgi, & Lerma, 2012). CES, for instance, provides a vast database of materials and their properties, allowing designers to find, plot, and compare materials data.

Besides their functional roles in embodying products, physical materials inspire and enable designers to explore and navigate the solution space (Halskov, Christensen, & Wiberg, 2018). Furthermore, they are instrumental in creating tangible manifestations and representations of the intended design (e.g., Brandt & Grunnet, 2000; Buchenau & Suri, 2000; Ehn & Kyng, 1992). Field observations and interviews with product designers affirm that they largely rely on their personal and professional experiences with materials (van Kesteren, 2008; Karana, 2009; Pedgley, 2014; Petreca, 2016). They visit materials fairs (e.g., Material Xperience Fair by Materia) or materials libraries (e.g., Materials ConneXion) and collect material samples and product parts to expand their repertoire of new materials and trends as well as to touch and feel new materials. It has been argued that such hands-on experience with samples of new materials compensates for the limitations of property profiles and data sheets in capturing and imparting aesthetic experiences and meanings of materials (Akin & Pedgley, 2016). Yet, over the past decade, design researchers have developed tools and approaches for materials selection, to deliberate over experience-related aspects of materials and include them more systematically in the design process beyond individual experiences of designers (e.g., van Kesteren, 2008, Karana, 2009, Rognoli, 2010, Zuo, 2010; see Pedgley, 2014 for an overview). To incorporate a phenomenological understanding, most initiatives rely on user-centered approaches, such as interviews and focus-group studies, and propose novel approaches to include stakeholders in materials decisions (Pedgley, 2014).

A more recent development in materials and design concerns a growing number of “experimentalists” and “makers” among artists, designers, architects, and engineers with a focal interest in (materials) fabrication (see Karana, Barati, Rognoli, & Zeeuw van der Laan, 2015; Kolarevic & Klinger, 2008; Kretzer, 2017). Technological developments, namely advanced and smart materials and new means of digitally enabled materials production, as well as concerns regarding sustainability, democratization of technologies and empowerment of societies (Tanenbaum, Williams, Desjardins, & Tanenbaum, 2013) are closely linked to this persistent design movement. As a consequence of such technological and social developments, the largely linear and standardized interface of design and materials in the twentieth century is giving way to the collaboration of diverse interests and a rigorous exploration of alternative, non-linear, non-standard design and materials practices (Kolarevic & Klinger, 2008).

Among the multitude of contemporary creative making practices, we may recognize the resurgence or return of crafts (Ferris, 2013) and small-scale, localized manufacturing initiatives emerging around the more technologically inclined maker movement (see Landwehr Sydow, 2017). Starting off as non-specialist sidesteps of the more professionalized studio crafts and individualistic hobbyist projects, craft activism and the maker movement have attracted considerable public interest. Despite significant differences in their materials and techniques, they both share “a spirit of independent making and creative problem-solving outside of mainstream commodity culture” and operate at (small) scales to retain an intimate relationship with media and materials (Ferris, 2013, p. 3). The movements emphasize learning through doing (active learning) and transcend traditionally separate domains and ways of working, while typically being connected to wider open source communities that support informal, networked, peer-led, and shared learning (e.g., through Facebook interest groups and YouTube).

Fundamental to these ongoing developments is a new attitude towards achieving design intent through interrogating materiality (e.g., Karana et al., 2015; Kolarevic & Klinger, 2008), a return to “making,” and a shift of paradigm towards material-driven design approaches (Karana et al., 2015; Oxman, 2010). As evidenced by DIY materials practices (Rognoli et al., 2015), and experimental architecture (Kolarevic & Klinger, 2008), the new generation of designers are willing to learn from freewheeling, open-ended, but doggedly focused forms of design research and experimentation (Steele, 2008). Their practice pushes beyond the existing formulas and design guidelines of existing materials, as evidenced by the growing number of commercial materials and machines developed by designers, such as Precious plastic machines by Dave Hakkens, conductive paint by Bare Conductive, and plastic flossing machines by Polyfloss Factory. As such, we are witnessing how design practice is moving beyond selecting materials and exploring the “application potential” of materials. Even when these practices result in product applications, as Karana et al. (2018) emphasize in the case of growing design,1 such applications are often hypothetical (i.e., not feasible to produce as consumer products in their current state of development), archetypical (i.e., maintaining typical forms or functions), and/or they use the grown material as a surrogate for a conventional material.

The Materials Potential Framework

As the creative contribution of designers to materials development is shifting from finding application potentials to an expanded definition of discovering materials potential in the blend of fabrication, application, and appreciation (i.e., user experiences), a new conceptualization is required to discuss what those potentials are.

When we talk about potential, we typically refer to “latent qualities or abilities that may be developed and lead to future success or usefulness” (Oxford Dictionary). Thus, it is about qualities and abilities that are not yet actualized. In the context of creative practices with materials, researchers and practitioners commonly talk about form possibilities (e.g., complex, organic, etc.), expression potential (e.g., for textiles, Nimkulrat, 2009), performative potential (e.g., Barati, Giaccardi, & Karana, 2018; Barati, Karana, Jansen, & Claus, 2018), and application potential in relation to the functions a material might serve. In engineering design, the potentials might be further quantified in terms of cutting cost and enhancing technical performance, such as “impact resistance,” relative to existing measures.

Methodology

In order to investigate how materials potential has been conceptualized in design to date, we conducted an extensive literature review of some established and relatively new conceptual frameworks within the materials and design domain. In parallel, we collected a variety of materials-driven design examples (both classics from the history of design and novel ones) which were verified by the testimony of designers. Sources for example cases included various design blogs such as Dezeen and Core77, materials and design books, such as Making It: Manufacturing Techniques for Product Design by Chris Lefteri (Lefteri, 2007), journals and conference proceedings, as well as materials and design related competitions, for example the New Material Award website (www.newmaterialaward.nl). We also added our own material-driven design project, which we could closely monitor, to the pool of collected examples.

We analyzed the existing frameworks by a back-and-forth consideration of the material-driven design examples. We identified three categories which could explain how materials potential was conceptualized in product design to date: form as materials potential, which refers to the abilities of materials to shape the product; function as materials potential, which refers to the potentials of materials to serve functionality in use; and experience as materials potential, which refers to the potentials of materials to elicit experiences from people in their situated interactions with products, including a range of emotions, meanings and actions. In the literature, these categories are also predominantly used to describe designers’ creative contributions to material-driven design projects. To our surprise, there has been no framework to date to identify and discuss the creative contribution of designers at design time (i.e., in the process of making), especially in the absence of a final product. To complement the dominant product-centered structures and to understand designers’ contributions and innovations at the scale of materials, our framework leverages the richness of an existing concept, affordance. A fourth, emergent category, affordance as materials potential, has a foundation in well-referenced design theory literature and anthropological studies of material and making practices (e.g., Malafouris, 2012; Glăveanu, 2014).

Below, we present these four categories with several representative material-driven design cases. In order to select these representative cases, after the initial back-and-forth examination of the categories and examples, we grouped the cases which we thought best illustrated a category related to the framework (e.g., a case in which the potential of a material is most apparently linked to a unique form expression by the designer). An initially categorized case was finally considered as a “representative case” in explaining the proposed framework if salience of the specified material potential category was agreed upon by three independent design experts (10+ years of experience).

Form as Materials Potential

The relationship between material and form is a critical and controversial one in the history of art and design (Lloyd Thomas, 2007). For a long time in Western philosophy, material was considered subsidiary to form, and merely its manifestation (Jeska, 2008). Later this view was challenged by scholars who believed that every material should take on its appropriate form (e.g., Gottfried Semper, as cited in Jeska, 2008). The phrase form follows materials (Jeska, 2008; Ashby & Johnson, 2003) emphasizes material as a characterizing element of design. This implies that “every material possesses its own language of forms,” which have come into being with and through materials (Loos, 1982, p. 66).

In design, form concerns a product’s sensual qualities, particularly its visual appearance (e.g., shape, volume, composition). Imagining materials as forms that are yet to become is possible only by a conceptual separation between form, structure and material. Moholy-Nagy (1947) instead refers to a shape “arrived at” or “valid in” a material. In other words, it is only in retrospect that we can reflect on how the material might have enabled certain shapes. However, geometric-driven form generation, carried into the development and design logic of computer-aided design (CAD), has largely institutionalized the prioritization of form over material (Pantazis, 2013). As a consequence of such developments, but also informed by the precedent examples and their prior experiences with materials, designers often speak about the form freedom and form possibilities of a material.

The close and inseparable interaction between shape, material and manufacturing process has been emphasized in most material selection models (e.g., Ashby, Shercliff, & Cebon, 2007). The manufacturing process has a two-way relationship with material and shape. It is obviously influenced by the material (e.g., sewing may not be a suitable process to join metals), and at the same time it determines the shape, the size, and, to a large extent, the cost of a component. The ability of materials to be shaped and finished in a certain way indicates their powerful potential to embody certain forms and possibly renders the creation of other forms difficult (or invalid).

Plastics have long been associated with industrialization and the standardization of forms made through high-speed machinery, such as injection molding. Figure 1 illustrates two famous design examples in which unique fluid organic forms, more in line with “being plastic” (plasticity) have been created, challenging the existing associations of plastics with “unified” and “perfect” machine-made forms. In the Amazonia vase, for instance, Gaetano Pesce achieves unique forms with bubbles, imperfections, and slight variations in size. The Fresh Fat Chair by Tom Dixon explores form possibilities intrinsic to polyethylene terephthalate glycol, a polymeric resin used for profile extrusion where high clarity, high gloss and good resilience are desired. The spaghetti-like strand of plastics is manipulated by hand and the result is glistering pieces of furniture that look as though they were made of liquid glass.

Figure 1. Designers push for novel forms by challenging the existing associations of plastics with “unified” and “perfect” machine-made forms: left, Clear Vase by Gaetano Pesce; right, Fresh Fat easy chair by Tom Dixon, 2001. Image source: left, Guggenheim Museum Bilbao; right, San Francisco Museum of Modern Art, gift of Gretchen and John Berggruen, photograph - Ben Blackwell; reprinted with permission.

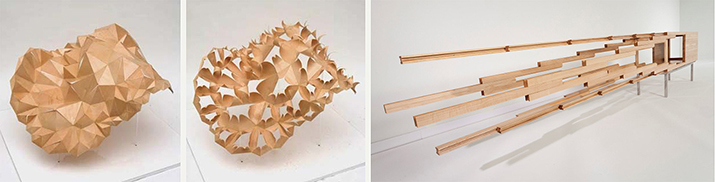

Figure 2 shows two examples of novel forms made with natural wood. Pinch, a seat by Matthias Pliessnig, takes advantage of steam bending techniques to unlock the potential of wood to be shaped into complex forms with double curvatures (Figure 2, left). Steven Leprizé’s lighting pushes the form and expression possibilities of wooden veneer by skillfully processing it and combining it with another material (i.e., rubber). In both examples, materials potential might be understood and described in relation to creating novel forms.

Figure 2. Novel static and kinetic forms made with natural wood: left, Drift by Matthias Pliessnig (image by Soomness, available under a CC BY 2.0 at https://flickr.com/photos/143850343@N06/); right, WooWood by Steven Leprizé (image source: ARCA; reprinted with permission).

With the advancement of smart and computational materials, the temporal dimension of form has gained prominent attention, and is termed temporal form (Vallgårda, Winther, Mørch, & Vizer, 2015). Temporal form in so-called computational composites is enabled by the computational structure, and materials enable the “material manifestations of temporal forms that enable our interactions with computational things” (p. 1). The temporal dimension of physical form, however, does not have a causal relation with computation, meaning that materials do not always need computation to reveal the temporal dimension of their physical forms. In fact, there are many non-computational designs that invest in natural changes in material properties and forms, both over time (e.g., graceful aging, Bridgens, Lilley, Smalley, & Balasundaram, 2015) and in relation to their environment and use (e.g., Jane Scott’s responsive knit project).

Figure 3 presents two kinetic wooden “skin” designs. In the work of Menges & Reichert (2012) at left, the wooden veneer changes shape when absorbing moisture from the air, pushing for a novel kinetic form by exploiting its unique hygroscopic characteristics. The role of wood in the kinetic shape of Explosion Cabinet by Sebastian Errazuriz is however more symbolic, reinforcing the image of a conventional material used in a conventional box-like cabinet. The expressive envelope of the kinetic form (i.e., from “intact” to “exploded” and vice versa) is pushed by the designer’s reinterpretation of the sliding dovetail joint commonly used in cabinetmaking.

Figure 3. The passive (left) and active (right) role of wood in conceptualizing kinetic forms: left, shape-changing wooden veneer; right, Explosion Cabinet by Sebastian Errazuriz (image source: left, Steffen Reichert, 2008; right, Carnegie Museum of Art, Pittsburgh, Women’s Committee Acquisition Fund; reprinted with permission).

Drawing on DiSalvo’s (2006) distinction between form and expression, the latter is “how the materiality of the product is rendered by design” (p. 40). To explain how expression reflects designers’ worldview, DiSalvo compares the works of Dieter Rams and Etorre Sottsass, and argues that while both designers shared a common belief that designers can influence the experience of use, one approached this by minimizing the expressiveness of the product (i.e., the product becomes a tool), and the other by perturbing the environment. In her practice-led research, Nimkulrat (2009) explores the relationship between paper string and artistic expression and elaborates on how the material (i.e., paper string) was important in her creative practice: “I recognised the expressive potential of the chosen type of paper string when making the artworks in this series and imagining them being in a particular exhibition space” (p. 57).

The interplay of the designer’s acts of “making” and “imagining” brings to the world of the actual “a deep dimension of the world that exists in a hidden and unexpressed form, waiting to happen” (Nimkulrat, 2009, p. 82; cf. Merleau-Ponty, 1968). Her research emphasizes the active quality or expressivity of the material in informing the artist about how to proceed with the creative process.

Function as Materials Potential

Function refers to the utility goals of a product or more generally “the work a product is designed to do” (DiSalvo, 2006, p. 43). For instance, the first and foremost function of a chair is to enable sitting. Function is a key concept in producing descriptions of artefacts (Roozenburg & Eekels, 1995; Suh, 1990) that explicitly address how users derive benefits from their use. Even though in design and engineering research the concept of function is often used in relation to the physical goals of artefacts (e.g., Vermaas & Dorst, 2007; Galle, 2009), some design theorists have argued that it is difficult to separate a product’s functionality from its aesthetic qualities (e.g., Papanek, 1972; Crilly, 2010). Drawing on Papanek’s notion of “function complex”—a set of functions that includes “association” and “aesthetics”—and the work of Searle (1995) and of Parsons and Carlson (2008) among others, Crilly (2010) elaborates on a broader range of non-technical function classes such as “aesthetic functions” and “social (or status) functions.” He argues that these classes of function might be further qualified as “proper” or “latent/manifested,” anchoring both to design intentionality and actual use. According to DiSalvo (2006) the “how” of the relationship between “operational” (both technical and social) and “aesthetic” functions of a product is dialogical to design expression (i.e., style; see previous subsection), and to the overall experience of a product (discussed in the next section).

Materials, due to their structural and other functional roles (e.g. heat conductivity) in products, contribute to their utility/use, or “functional justification” (Moholy-Nagy, 1947). Linking materials and their properties to the well-justified functions of existing artefacts provides an effective way to articulate the potential value and benefits of those materials. The potential of the material thus can be framed in allowing for the function(s) to be achieved more efficiently.

Figure 4 illustrates novel functions of vinyl film and of mycelium. The first example is the zipper and button free bag series Furoshiki Shiki, by Samira Boom. Furoshiki Shiki, meaning “furoshiki style” (furoshiki is a type of traditional Japanese wrapping cloth) consists of products made out of one sheet of semi-transparent vinyl film. This sheet is turned into a bag by folding it, using the adhesive qualities of the material. The same “adhesive” quality of vinyl is emphasized in the sticky vinyl film product for children (Figure 4, middle). The second example is the mycelium-based packaging by Ecovative. The foam-like mycelium-based material, which is fabricated by inoculating an individual strain of fungus into a substrate of organic substances, can biodegrade and has high insulation qualities (Appels et al., 2019). This combination of qualities inevitably leads to the functional relevance of mycelium-based composites as short-life packaging products for protecting goods. The product retains the typical look of a packaging solution made of polystyrene foam.

Figure 4. Materials potential can be articulated in relation to materials’ structural and functional roles in product applications: left, Furoshiki Shiki, and middle, San Kaku Mado (triangles), made of sticky vinyl film, by Samira Boom (image source: left, Christien van Dokkum; middle, Nakano Ougi; reprinted with permission); right, wine packaging and photo by Ecovative (reprinted with permission).

The examples suggest that the functional potential of materials might be discussed without explicit reference to the product form or the making process. The compatibility of function and language (in producing analytical descriptions of non-existing artefacts) yields the notion of power and privilege (over form) in the discussion of materials potential. Ashby’s (1999) model for materials selection in mechanical design makes materials selection operational by translating artefacts into (technical) functions (i.e., what the product or the product component does), and materials into attribute profiles. The materials potential to serve functionalities in products becomes a matter of mapping between predefined functions and certain material attributes. For instance, certain textiles might be considered to be appropriate for upholstery (i.e., providing furniture with padding and fabric cover) because of their specific sets of attributes, including their weave structures and durability. This does not necessarily mean that designers could/would not consider them for designing a wearable piece. The functional justification for using them is affected by the extent to which the property profiles of those materials match the functional design requirements.

Experience as Materials Potential

Moving beyond usability measures of (interactive) products (Norman, 2004) and placing emphasis on “affective” qualities in experiencing them (Desmet & Hekkert, 2007), experience design (Hassenzahl, 2010) or design for experience (Schifferstein & Hekkert, 2008) has become a meta school of thought/movement in product and interaction design with myriad heuristics, methods and tools (see Hassenzahl, 2010).

Materials as the building blocks of products, charged with (sociocultural) meanings (Karana, 2009; Wilkes et al., 2016) play an important role in shaping our experiences of products (Karana, Hekkert, & Kandachar, 2008; Karana, Pedgley, & Rognoli, 2014). Ashby and Johnson (2002) acknowledge that the mechanical design model misses out the user–product interaction aspects and elaborate on the role of materials and fabrication processes not only “to convey information and respond to user actions,” but also to influence “the aesthetics, associations, and perceptions of the product” (p. 35). Understanding how materials are experienced by people and identifying patterns of materials experience (Giaccardi & Karana, 2015) has thus become an important focus for materials selection in designing for “meaningful” experiences. User-centered inquiries (e.g., interviews, focus groups) and ethnographic studies in particular contexts of use (Wilkes et al., 2016) are among the methods to collect relevant data about material experiences (see e.g. Fisher, 2004). While experience design can depart from the known needs and values (Hassenzahl, 2010) with the material chosen for the benefit of the experiences, the experience vision can also be deliberated to reveal novel potentials of the material in material-driven design (Karana et al., 2015).

Karana et al. (2015) propose that characterizing materials in terms of their “sensorial,” “affective,” and “interpretive” qualities as well as their “performative” qualities can help with the identification of their experiential potential, that is to say their potential to elicit experiences. The identification/conceptualization of these four levels of materials experience (Giaccardi & Karana, 2015) was aimed at structuring and articulating the experiences of materials in human encounters and practices.

Figure 5 presents two renowned design examples to illustrate how potentials of the material can be elaborated in relation to the experiences and performances elicited by the designed product. The first example is the Light Light chair, by Alberto Meda. The chair, by design, looks too fragile to withstand the average weight of an adult person. The designer leveraged the exceptional physical and mechanical properties of the composite material to make the thickness of the chair’s legs and body below the threshold of what most users expect as functional and perhaps safe. The second example, the Soft Washbowl, designed by Hella Jongerius, is made of rubber. Despite its archetypical form, the washbowl is flexible, and thus can be bent and deformed. The new experiential qualities of the bowl, for example at the performative level, are expected to change the performance as well as practices around it. For example, one could twist and wobble the bowl to clean it under running water. In both the Light Light chair and the Soft Washbowl, the designers have tapped into our expectations for materials to perform in certain ways and/or a norm of efficient functionality (Niedderer, 2007) in order to elicit particular experiences, such as surprise.

Figure 5. Understanding material potentials in relation to the experiences and performances elicited in interactions with products: left, Light Light chair by Alberto Meda; right, Soft Washbowl by Hella Jongerius, (production by Droog Design). Image source: left, Hella Jongerius; right, Museum of Modern Art, New York; reprinted with permission.

Attention to the performative qualities of materials and the possible links between material properties and the performed actions observed in user–material interactions has resulted in material-driven design projects with an explicit intention to push the “normative” action repertoire (e.g., Barati, Giaccardi et al., 2018). Two recent examples of such material-driven design projects with electroluminescent (EL) materials and mycelium are A Drop of Light (Barati, Karana et al., 2018) and Second Skin (Karana, Blauwhoff, Hultink, & Camere, 2018), as shown in Figure 6. The former is a prototype that showcases the potential of EL materials in unlocking new performances when interacting with water and rain, thanks to the semi-transparent, water-activated EL parts. The latter is a packaging solution that exploits the friability and biodegradability of the mycelium-based material in creating a distinct unboxing experience.

Figure 6. The experiential potential of materials: left, the umbrella pushes for a novel experience of rain, through the custom-made water-activated EL print (designed by Stan Claus; image source: Weirsma Brothers; reprinted with permission); right, mycelium-based packaging design, by Davine Blauwhoff, offers a distinct unboxing experience (reprinted with permission from Davine Blauwhoff).

Summary of Accounts

So far, we have shown how materials potential can be conceptualized in relation to the notions of form, function, and (materials) experience. Even though these notions are conceptually separated, in reality form, function, and experience as materials potential are rather intertwined, as they affect and result from each other. For example, a material might simultaneously enable surprisingly (i.e., experience potential) thin yet strong shapes (i.e., form potential) to sit on (i.e., function potential). However, such understandings of materials potential do not reflect how novel material potentials actually come about in creative practice. This may reinforce the view that material potentials are materials’ ever-existing effects awaiting the creative mind to recognize them, independent of the fluxes of the creation process, the designer’s skills, the properties of the medium used to communicate the material (e.g., technical information, video of the making process, the processed material, or the ingredients), the social context (who the designer interacts with), time, and place (what equipment the designer has access to).

The distinction between concepts and percepts, as two modes of acquiring knowledge (James, 1895, 1890/1981) is helpful in bringing into sharper focus why we need to complement the existing understanding of materials potential with yet another notion, affordance (see Faraj & Azad, 2013; Heft, 2003). In the analysis so far, we have treated material potentials as concepts, meaning that they can be uncovered through analyses of the material and its possible relations to product function, form, and levels of materials experience (e.g., performative level). Concepts according to James (1910/1996, pp. 73-74) play distinct parts in (1) steering us practically by providing an immense map of relations among the elements of things; (2) bringing new values, insights, and points of emphasis into our perceptual life; and (3) making a frame out of things, an independent existence, even in the absence of sense, i.e., the phenomenon of immediate (unmediated) experience. For instance, materials properties are quantitative concepts that are developed to communicate materials information in materials science and engineering disciplines, and serve as a metric by which the functional benefits of one material versus another can be inferred.

On the other hand, conceptualizing materials potential as percepts means that knowing about them requires immediate (i.e., unmediated) experience and awareness of the qualities of the material. As James explains, immediate experience consists of objects and their relations, as well as a suggestion of what possibilities may follow, while still unrealized (i.e., feeling of tendency; Heft, 2001). In our everyday creativities, we are perceiving and exploiting the potentials of materials without deliberately reflecting on those relationships. The early stages of materials development imply that there have not been any (or many) design precedents and possibly designers lack the necessary body of knowledge and experience to rely on in analysis of the materials potential. These early conditions make it difficult for designers to think about form-possibilities of a new material, based on a picture of it or an abstract knowledge of its technical properties.

Affordance as Materials Potential

Design researchers have found the notion of affordance, introduced by Gibson (1979), relevant in design due to its cutting across traditional subject–object dualities (e.g., Gaver, 1996; Norman, 1999). Despite debates on the nature and scope of the notion (Rietveld & Kiverstein, 2014; Lanamäki, Thapa, & Stendal, 2016) there is widespread agreement that affordances are possibilities for action offered to an animal by its environment, that is to say by the substances, surfaces, objects, and other living creatures that surround the animal (Chemero, 2003, 2009; Heft, 2001; Reed, 1996). There have been debates among scholars whether affordances are dispositional properties of the environment (e.g., Reed, 1996), or rather relations between features of the environment and the abilities of organisms (e.g., Chemero, 2003). Others, such as Rietveld and Kiverstein (2014), have found ways for affordances to be both relations and a resource.

An immediate benefit of affordance in conceptualizing materials potential, as argued by Gaver (1996), is that it enables descriptions of materials in terms of process-abilities. Accordingly, a potential of leather might be that it can be embossed and even tattooed, as seen in the leather iPad case INKO by Alexandre Echasseriau (Figure 7). What the designer demonstrates with the iPad case is a way and knowhow to fabricate robust printed circuits, revealed through working skillfully with the affordances of the conductive ink, the leather, and the tattooing machine.

Figure 7. A novel potential of leather is unlocked through the skillful act of tattooing with conductive ink: left, iPad cover and keyboard INKO; right, the leather being tattooed with conductive ink (design and photo by Alexandre Echasseriau; tattooing by Tatoué and Jeremy Lorenzato; conductive ink: Bare Conductive; reprinted with permission).

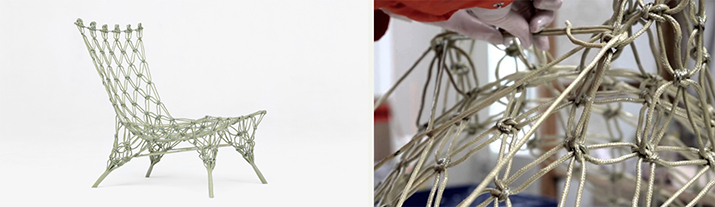

Figure 8. Designer’s intervention in the process of making brings out the “textile-ness” of carbon fiber: left, Knotted Chair by Marcel Wander; right, shaping the hand-braided cord impregnated with epoxy resin (reprinted with permission from Marcel Wander).

In the history of design, we find numerous instances where designers intervened in known production techniques in one way or another, giving rise to new process-abilities. For instance, in designing Knotted Chair, Marcel Wander revealed a new way of creating volumes with carbon fiber composite, instead of making sheets, to bring forth the textile quality of carbon fiber. Here, the novelty is not in separately perceiving the braidability of the carbon fiber cord or the ability of the cord to harden when impregnated with resin, but in combining and sequencing the two in such a way that the 3D volume could be fabricated. Knotted Chair is a good example in which the other categories of materials potential are to a great extent interlocked in describing the designer’s creative contribution to materials development and product design. The hand-braided chair elicits an emotional response (i.e., experience) in connection to its strong and rigid body that can withstand the weight of an average adult person, despite its delicate textile look.

The convenient and useful definition of affordances as possibilities for action, however, can obscure the richness of the concept in explaining how novel affordances are discovered (e.g., Rietveld & Kiverstein, 2014; Glăveanu, 2012). Lanamäki et al. (2016), in a literature review paper, identify four “stances” of affordances: “canonical affordances,” which are universal action-possibilities bound with specific ways of living, for instance, chairs provide sitting. We may notice overlaps between canonical affordances and the notions of function in the design literature (e.g., Niedderer, 2007). The second stance is “affordance as completed action,” which conceptualizes affordances as inseparable from the situated actions of the individual. This seems to overlap with the performative level in analyzing material experiences (see previous section), as it concerns how particular people in particular “situational wholes” perform as they do. Borrowing from Dewey (1934/1980), for Giaccardi and Karana (2015) a situational whole is “the whole complex of physical, biological, social and cultural conditions that constitute any experience.” They emphasize the need for such a holistic understanding of how materials, people and practices come into relation here and now, and over time, in order to describe a materials experience. This holistic view is indeed useful for describing and understanding user experiences (Bratteteig & Verne, 2012). However, it does not cover the space for action, nor the action possibilities that emerge in the making, which might facilitate designing for novel material experiences. The third stance considers affordances as qualities and resources that can be designed into artefacts, for instance the fact that the (physical) design (i.e., form) of a door handle can be modified in ways such that it affords pulling/pushing. The fourth stance views affordances as opportunities for action (Stoffregen, 2003, p. 124) that may or may not have been intended, but emerge through action (Leonardi, 2012). Lanamäki et al. (2016) made distinctions between the third and fourth stances, referring to them respectively as “design affordances” and “potential affordances.” Drawing on the fourth stance, affordances as potentials of a material are explored through interaction with them and cannot simply be “built into” or “read out of” artefacts (Fisher, 2004). This conceptualization of affordance emphasizes the generative role of immediate experience and material engagement in discovering novel affordances. As Carr (1989) explains: “In the midst of an action the future is not something expected or prefigured in the present, not something which is simply to come; it is something to be brought about by the action in which I am engaged” (p. 36).

Affordance as materials potential is what a specific material has to “offer” in the collaborative act of people, materials, making (processes), and the surrounding environment. It is “to consider the action potentials embedded within the environment and available to creators for use or change, and thus, ultimately, to re-conceptualize agency and intentionality” (Glăveanu, 2014, p. 61). In the theoretical discussion of how novel affordances emerge, the relation between affordance and intentionality, and the (conditions for) emergence of affordances over time become central. The latter brings to light developmental (micro-scale) and historical (macro-scale) discourses on the co-evolution of affordances, which we briefly touch upon.

Design practitioners and researchers have reflected on the relations between affordances and (design) intentionality in various creative practices. Franinović (2013) describes her (material-driven) design activity as being governed by “following what the materials afford,” rather than “trying to impose ideas on matter by controlling their physical properties.” In her making practice with paper strings, Nimkulrat (2009) considers both scenarios of letting the material “speak” freely for itself, and of seeing the material speak under her control (i.e., prior manipulation). Intentionality, as a component of extended cognition (Malafouris, 2008), is “an orientation towards the world, shaped, at each moment, by both person and the environment” (Glăveanu, 2014, p. 88). It seems that various kinds of “knowhow,” including a set of skills, stances, assumptions and habits, give rise to a state of “prior intention,” i.e., the intention to act precedes the action itself (Searle, 1983). In material practices such as pottery, the line between human intentionality and material affordance becomes more difficult to draw, to the extent that the former may identify with the latter (Malafouris, 2008).

According to the relational conceptualization of affordances (e.g., Chemero, 2003), the individual’s ability and skills make affordances available to them. Franinović (2013) argues that in creative processes that involve hands-on experiments with materials, “hidden” affordances begin to emerge. Their emergence cannot be explained unless both the developing skills of the designer and the resourcefulness of those materials come into play. More generally, we can say that skilled agents are (or become) able to “collaborate” (Ingold, 2013, p. 128) with the socio-material surroundings, through “learning how to deal with these very specific material settings” (Rietveld & Kiverstein, 2014, p. 333). Going beyond the individual and her situated actions, Rietveld and Kiverstein propose that affordances are as much relations between aspects of environment as skills available to a “form of life.” Borrowing the notion of form of life from Wittgenstein (1976/1993), they consider affordances relative to the accumulated skills available to a community, who share relatively stable and regular ways of doing things.

By locating affordances in the context of a form of life, affordances can be given a reality independent from any individual’s actual engagement with them here and now, or percepts (Reed, 1996; Rietveld & Kiverstein, 2014). They become resources the environment offers (Reed, 1996) or potentials for action available to the form of life to pick up, even before anyone actually does so (p. 338). Such a conceptualization of affordances makes it possible to describe and prescribe the discovery of novel affordances, namely “by stimulating the application of an existing skill to different aspects of the environment” (Rietveld & Kiverstein, 2014, p. 339). The earlier example of the tattooed leather circuit (Figure 6) is a clear example of how an existing skill/technique/tool unlocked the perception of novel affordances of leather and conductive paint.

Unlocking Novel Affordances in Material-Driven Design

Creativity in the crossovers of materials and design seems to go beyond a “general” problem-solving activity. There is no doubt that past experiences/engagements with existing materials, and visual comparison tools between property profiles, enable designers to make hypotheses about new materials, and predictions about how they might be processed and experienced. However, for those thoughts and imaginations to be realized in the world, affordances of the environment (in relation to the materials, existing skills, techniques and tools) become the conditions. Conceptualizing affordances as materials potential brings to attention the limitations of precedent-based reasoning (Oxman & Oxman, 1998). As long as creativity is assumed inside designers’ minds, the “extended intentionality” (Malafouris, 2008, p. 16) that is intimately linked to novel affordances remains largely unexplored. A recent interview with designers involved in a collaborative material development project suggests that designers settle for low-hanging material potentials if the conditions for discovering novel affordances do not present themselves (Barati et al., 2019).

According to Glăveanu’s (2012) framework of creativity, novel affordances fall into three spaces of possibilities marginal to what is usually done, as the material, personal (i.e., intentional) and sociocultural constraints interact with one another: “unperceived affordances,” “uninvented affordances,” and “unexploited affordances.” Unperceived affordances are action potentials that are materially achievable and do not violate any particular cultural norms, but designers are unaware of their existence and thus have no explicit intention of making “use” of them. Tinkering and experimenting with the material out of curiosity, accidents and even mistakes may contribute to bringing those unnoticed action potentials to a designer’s attention (e.g., Franinović & Franzke, 2015). The history of inventions provides great examples of how materials engagement and experimentation can lead to spontaneous discoveries (e.g., Teflon). Uninvented affordances are those possibilities of action that are favored by the designer and the society but are not yet available. An invention of new tools and techniques, or repurposing existing ones (Rognoli et al., 2015) can unlock such novel affordances, enabling the designer to combine or transform the basic capacities of the material. Unexploited affordances are action potentials that remain unexploited due to a certain normativity embodied in the socially accepted ways of thinking about or interacting with the material world. Such novel affordances might be unveiled through transgressions of (cultural/professional) norms (see Glăveanu’s analysis of Romanian “egg decoration” craft practice for more details).

Many material-driven design practices have contributed to the unlocking of novel affordances through the mechanisms of spontaneous discovery, invention of techniques, and transgression of norms, or a combination of them.

Spontaneous Discovery in Material-Driven Design

Materials experimentation and practical inquiries are often pregnant with accidents, which may lead to perceiving novel affordances and possible ways in which a material can change. An example of a spontaneous discovery has been reported in the work of Franinović and Franzke (2015) with electroluminescent (EL) materials. Franinović and Franzke note how their curiosity-driven experiments with an unfinished (semi-processed) sample opened up new possibilities to explore the material’s responsive behavior. The action potentials, such as to print EL layers on separate sheets, to change the layers’ topology, or to partly replace the printed conductive layer with liquid/textile conductive materials (Figure 9, left) have allowed for diversification of EL materials’ performative qualities (e.g., Barati, Giaccardi et al., 2018). As shown in the example of A Drop of Light (Figure 6) the newly perceived affordances unlocked material expressions and experiences, different from conventional EL applications.

Figure 9. Discovery and perception of new affordances through materials experimentation: left, water-activated electroluminescent sample (design, fabrication, and photo by Stan Claus; reprinted with permission); right, MycoTEX textile and dress made from aggregated pure mycelium pieces by Aniela Hoitink | NEFFA (image source: Aniela Hoitink | NEFFA; reprinted with permission).

As previously mentioned, mycelium-based materials have been used in packaging design, in relation to their “polystyrene foam-like” characteristics and “crumbling” qualities. In both examples, mycelium-based composites are grown into pre-defined molds and come as massive/bulk structures. Aniela Hoitink, in her practice with mycelium, explored other ways of shaping mycelium-based materials for creating textile-like materials. The experimentation with pure mycelium led to the designer’s perception of its affordance to glue the disc-shaped pieces together as they dry, and to create garments out of separately grown pieces, eliminating the need for cutting and sewing (Figure 9, right).

Understanding materials and technologies as reconfigurable, dynamic, and emergent composites/assemblies (see De Landa, 2011) that can be directly fabricated, orchestrated and manipulated by designers has significantly enlarged the scope of materials’ unperceived affordances. An example of composite fabrication in pursuit of the unity of skin, structure, and effect (Kolarevic & Klinger, 2008) is BioLogic fabric by MIT Media Lab & Royal College of Art, incorporating bacteria on fabric substrates to create a variety of bending behaviors in response to sweat and humidity. Perceiving the behavior (e.g., to expand and contract in reaction to moisture) and affordances (e.g., to be assembled on thin fabric) of the microorganism Bacillus subtilis was key to the novel deployment of these bacteria, which had been used for centuries to ferment foods in Japan. Out-of-the-box thinking in such experimental endeavors results from a much more informed knowledge base of the reciprocities between materials, their behavioral characteristics, and the systemic behavior of their assembly/composition (e.g., Kolarevic & Klinger, 2008; Menges & Reichert, 2012).

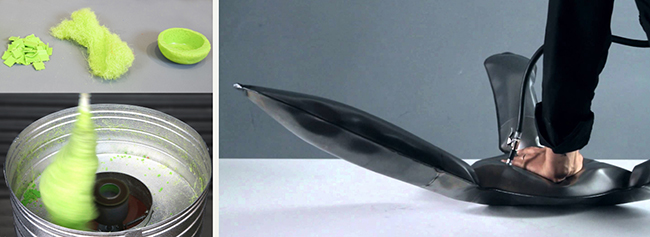

Invention of Techniques in Material-Driven Design

Invention of new tools/machines and repurposing, modifying, and combining existing production tools and techniques have been key to expanding novel affordances (for an overview, see Rognoli et al., 2015). The development of new machines such as multi-material 3D printers has enabled high-resolution control over dot deposition of soft, rigid, and transparent plastics in a single printed material. MIT Self-Assembly Lab showcased the possibilities of creating multi-material prints that can change shape “directly off the print bed” and termed this new way of production “4D printing” (Tibbits, 2014). New ways of production such as 4D printing have further opened up unprecedented design opportunities in terms of form and experience, see for instance shape-shifting noodles by MIT, enabled by 3D printing strips of edible cellulose over the top gelatin layer. Existing machinery can be equally relevant when it comes to pushing for novel affordances. The Polyfloss machine (Figure 10) is a clear example of how repurposing an existing machine has contributed to the invention (i.e., “floss-ability”) and exploitation of novel affordances of plastics (e.g., in making multi-structured forms) and enabled new ways of recycling plastic parts. As evidenced by FiDU, a metal inflating method invented by Oskar Zieta, combining different machines has capitalized on the known affordances of metal sheets (e.g., to be spot-welded, to apply hydroforming techniques) and exploits newly perceived ones (i.e., to be blown up into unique forms by playing with the pressure and thickness of the sheets).

Figure 10. Repurposing and inventing tools and techniques may unlock novel material affordances: top left, fiberized and molded polypropylene waste; bottom left, Polyfloss Machine by A. Gaulard, N. Paget, C. Machet and E. De Visscher, Royal College of Art, London, 2012 (image source: The Polyfloss Factory Ltd.; reprinted with permission); right, metal inflating by Oskar Zieta, 2011 (image source: Zieta Prozessdesign; reprinted with permission).

Transgression of Norms in Material-Driven Design

Another significant source of creativity in material-driven design practices comes from transgressing certain norms concerning how materials are processed and used, or what is considered as a material source.

Design activity might lead to exploitation of known characteristics of materials that were usually considered to be “undesirable.” The works of Menges and Reichert (2012) and Wojcik (2015), for instance, take advantage of the undesired “swelling” characteristic of wood (when moisture content in wood increases) in creating moisture-responsive and self-bending forms, respectively. Menges and Reichert further transgress a norm of superimposing external sensors to material constructs, by instrumentalizing hygroscopic material behavior. The instrumentalization demanded an in-depth understanding of wood veneer composites (e.g., their response range and behavior) through “making” in relation to the identified design variables, ranging from anatomy and direction of fibers, to geometry of the sample, to humidity control during the fabrication phase. The role of (performance-driven) digital simulation in estimating the emergent (kinetic) form, as a factor of dynamic interaction between the material, the composition/assembly and the environment, was emphasized (see also DeLanda, 2011).

Instances of creativity through transgressing norms of materials processing and fabrication are plentiful in contemporary design practice. Here, we demonstrate the category with a few examples. The first example relates to the glasswork of Gionata Gatto and Mike Thompson, called Trap Light. The transparent glass shade provides an engaging new lighting experience as it also functions as a light source, capturing and re-emitting scaping light. In creating the lamp, the designers took a fresh approach to a traditional Murano glassblowing technique (Figure 11, left) by embedding photoluminescent pigments into the glass body. Photoluminescence is a process whereby energy absorbed by a substance is gradually released as ambient light.

Figure 11. Designers exploit the potential for embedding photoluminescent pigments into the transparent body of glass, using a traditional technique: left, Trap Light by Gionata Gatto and Mike Thompson; right, Murano glass blowing process (image source: Studio Gionata Gatto; reprinted with permission).

The second example is Litracon, a precast concrete building block by architect Áron Losonczi that allows the transmission of light and shadow through it (Figure 12). Instead of collaging glass and concrete materials next to each other, which was practiced before, the designer aggregates thousands of glass fibers and mixes them with fine concrete to create a light-transmitting version of concrete without compromising the strength and texture of traditional concrete. The invented affordance, to embed thin glass fibers in fine concrete, is further leveraged in creating a distinctive structural facade for Al-Aziz Mosque in Abu Dhabi (Figure 12, right).

Figure 12. The previous practice of collaging glass and concrete materials next to each other is transgressed in the creation of light-transmitting concrete: left, precast building blocks by Litracon® (image source: Litracon®; reprinted with permission); right, Al-Aziz Mosque’s light-transmitting façade (design, production, and photo by LUCEM Lichtbeton®; reprinted with permission).

Recently, designers have pushed the known affordances of recycled plastics by transgressing the norm of plastic recycling, i.e., separating different types of plastics, and instead universally mixing them. In works of both Shahar Livne and Henry Louis Miller, we see that discarded plastics, regardless of their type, are ground and combined with soil/cement to create new materials. The transformation revealed affordances that were initially unperceived, such as hand-pressing the plastic compound into its final shape, resembling working with clay. Miller “uses” affordances of ground waste plastics to aggregate cement and make plastic concrete, a new material as strong as conventional concrete.

Another instance of transgressing norms in material-driven design practices is searching for and discovering unorthodox material sources, such as waste animal blood (by Basse Stittgen), and urban smog (e.g., Smog Free Ring by Studio Roosegaarde, and serVies by Annemarie Piscaer & Iris de Kievith). These creative practices with and through materials challenge the norms and conventions ascribed to materials, including their sociocultural meaning and their use. For instance, a realization of the potential of animal blood, discarded in large quantities by slaughterhouses, as a material source triggers Stittgen to further explore its “material-ability.” The designer exploits the known affordances of blood (e.g., to dry) to process it into a powder that can then be heated and pressed into a black, solid material. The process uncovers and exploits novel affordances of blood, or more specifically albumin protein, to act as a binding agent, in creating a protein-based biopolymer that is 100% processed blood.

Discussion

In this paper, we elaborate on the notion of materials potential in design to promote the view that design’s highest contribution to materials development is not merely the final product application. Designers can actively contribute to discovering novel affordances through their skillful, embodied, distributed acts of tinkering, experimenting, and making. The notion of affordances has offered a lens to understand and analyze how concrete practices in material design and material-driven design might be linked to designers’ intentionality through their “skilled” action (Ingold, 2013) and “skilled” cognition, which are responsible for their selective engagement with the rich landscape of affordances (Rietveld & Kiverstein, 2014). Our creative practices with smart materials (Barati, Giaccardi et al., 2018; Barati, Karana et al., 2018) and growing materials (Karana et al., 2018) suggest that novel affordances are a moment-to-moment collaboration of the material and the social, even when the action is initially driven by the intention of the designer. Bound to material engagement, the concept of affordances as materials potential enables us to take a step forward in understanding “the synergistic process by which, out of brains, bodies and things, mind emerges” (Malafouris, 2008, p. 58). The fruits of such experimental material research may focus on materials samples as much as on making recipes (see Ribul, 2013), industrial processes and production.

Understanding affordances as materials potential offers further implications for collaborative material development, which we will briefly address below.

Curiosity-Driven Approach in Collaborative Material Development

The affordances of a material are understood in and through material engagement, and do not require a reference to the final outcome (e.g., an experience vision, a desired form or function). This conceptualization legitimizes curiosity-driven and experimental approaches in search of novel material potentials. De Landa (2004) argues that new materials not only offer the potential for increased performance of a design, but also can lead to design proposals “changed by something that comes from within the materials” (p. 21). While collaboration might reward the approaches that generate the most valuable output (in terms of market value), solutionist approaches do not always turn out to be the most effective ones. There is evidence from medical studies that “shovel-ready” approaches do not necessarily result in the most valuable output (in this case medicines), compared to basic research and curiosity-driven approaches (Spector, Harrison, & Fishman, 2018). This means that even if the motivation of collaboration is solely for profitable outcomes, setting out an application-design oriented methodology might not be ultimately as productive as encouraging more curiosity-driven and non-direct experimental approaches. According to Olma (2016), in such collaborative projects, creative and innovative results are achieved through the autonomy of art and design disciplines, which is “the foundation on which the creative industries approach is built” (p. 37), rather than enthusiasm for the “surface” design of consumer goods.

For a collaboration to work out, the expected contributions from designers need to be in agreement with designers’ motivation to participate in such collaborative projects (see Hornbuckle, 2018). Mainstream product designers might not be willing to spend too much time to master a new material (the way craftspeople or material scientists do) or exploring novel affordances, when they already have a product concept with promising market prospects. It is important to find an optimum trade-off between dedicating too much and too little time to finding the affordances relevant to designers’ concerns. This can be achieved by involving designers (and artists) who are more inclined toward material design and experimentation and see reward and value in blurring the boundaries between product design and material making. Not only is this growing population of designers willing to spend time and effort on understanding materials, but they can also serve as proxies between materials scientists and other product designers in collaborative materials development. Their proxy function may involve activities including, but not limited to, simplifying the making/fabrication processes (e.g., screen printing EL materials; reusing scrap materials), demystifying the science behind technologies and materials behavior, demonstrating/visualizing basic working principles, boundaries, and potentials, and assisting with performance-driven computational models and simulation tools (Oxman, 2010).

On the other hand, promoting a curiosity-driven experimental approach does not mean that novel affordances cannot be uncovered in materials exploration that is part of a solutionist approach, i.e., to inspire new solutions for a predefined concept. In fact, in a solutionist approach, narrowing down the scope of materials exploration (e.g., focusing on surface finishing) might lead to more focused investigation (e.g., design requirements for hygiene), i.e., systematic tinkering. The desire to work with a specific material, i.e., material-driven design, leads designers to apply design strategies that are driven by material properties and behavior, to ensure that their imagination bears “sufficient causative relation to actual existing material possibilities, so as to render it plausible, and therefore (at least potentially) attainable” (Ferris, 2013, p. 1). To keep an open mind about unique material potentials, Karana et al. (2015) encourage designers to invest in an early “material understanding” step, in which both the curiosity-driven and solutionist approaches guide certain activities in an iterative manner, e.g., material explorations, systematic tinkering, material characterization (technical and experiential), and material benchmarking, which suggest comparing the material against other materials.

Communicating Material Potentials in Collaborative Material Development

The challenge of communication between materials scientists and designers in collaborative materials development and the need for an effective dialogue between the two communities have been discussed in the literature (e.g., Wilkes et al., 2016; Hornbuckle, 2018). To address this multidisciplinary challenge, researchers have proposed isomorphic material samples (Wilkes et al.), and materials liaison personnel who are familiar with both worlds (Hornbuckle, 2018). These tools and strategies tap into the mediating role of physical samples as “boundary objects” (Star & Griesemer, 1989), and the “liminality” of individuals who understand both designers’ and materials scientists’ languages (e.g., Lindsay, 2010). To explore and communicate the material and its potentials, designers rather aim for intermediate objects, such as material demonstrators (Barati, Karana, Jansen, & Hekkert, 2016). In experimental architecture, pavilions may similarly serve as “an experimental laboratory and a case study to introduce new ideas and techniques” (Bohnenberger, 2013). Such facilitations may be good for promoting some kinds of exchange and understanding by overcoming language barriers (e.g., Sundström et al., 2011), but are not suited to promoting material making abilities or to changing the social dynamics that arise from the knowledge (and thus power) gap between designers and materials scientists. Those require strategic and targeted interventions and purposeful project organizations that change the relationships between people and resources, for instance through pedagogy (Loi & Dillon, 2006) and participatory learning (e.g., Clapp, 2016; Vartiainen, 2014). Such interventions not only promote and foster cross-disciplinary abilities which can lead to new perspectives (Glăveanu, 2015) and possibilities for action (Rietveld & Kiverstein, 2014), and, by extension, equity (cf. Davidson, 2017), but also stimulate creative improvisation (cf. Dillon, Wang, Vesisenaho, Valtonen, & Havu-Nuutinen, 2013; Vesisenaho et al., 2017; Olma, 2016).

Conclusion