Cross-Functional Cooperation with Design Teams in

New Product Development

1 Seoul School of Integrated Sciences and Technologies, Seoul, Korea

2 Dongseo University, Busan, Korea

This paper identifies the critical factors of cross-functional cooperation for design teams in new product development (NPD) by means of a survey of 243 cross-functional team managers at consumer electronics firms. Scholars have recently suggested that the industrial design function is adopting a more prominent position in new product development as a means to create successful business, but the current nature of the design processes and the roles of various functional groups involved in NPD are areas that are under-investigated: limited empirical research has been done. The empirical research available defines eleven critical success factors for the achievement of effective cross-functional teamwork with design teams in NPD and provides evidence of the positive relationships of these factors with cooperative work performance.

Keywords – Cross-Functional Teamwork, Internal Design Team, Effective Product Development.

Relevance to Design Practice – This empirical study defines the key success factors for achieving effective cross-functional teamwork with design teams in NPD and provides evidence, using correlation analysis, of the positive impact of these factors on cooperative work performance.

Citation: Kim, B. Y., & Kang, B. K. (2008). Cross-functional cooperation with design teams in new product development. International Journal of Design, 2(3), 43-54.

Received November 1, 2007; Accepted August 14, 2008; Published December 31, 2008

Copyright: © 2008 Kim and Kang. Copyright for this article is retained by the authors, with first publication rights granted to the International Journal of Design. All journal content, except where otherwise noted, is licensed under a Creative Commons Attribution-NonCommercial-NoDerivs 2.5 License. By virtue of their appearance in this open-access journal, articles are free to use, with proper attribution, in educational and other non-commercial settings.

*Corresponding Author: bykim2@assist.ac.kr

Introduction

In-house designers have traditionally been viewed as a support group within an organization rather than as part of a managerial process or a business resource. In addition, the role of a design team has usually been part of a numerical and cultural minority process within a firm (Coughlan, 2002; Rassam, 2005). Some completed studies have shown that design teams frequently derive misinterpreted information in the cooperation process and that their briefs often contain unclear and superfluous information (Walsh, Roy, Bruce, & Potter, 1992; Herbruck & Umback, 1997). This situation has resulted in a lack of understanding of the role and process of design in NPD: the NPD process has been described as one in which cooperation with design groups is characterized by an uneasy integration with interrelated segments (e.g., engineering and marketing) (Donnellon, 1993; Baxter, 1995).

However, recently the role of design teams in NPD has been shifting. The complexity of the product or of the conceptual process in NPD requires working with an in-house design team in order to reduce uncertainties associated with long delays, high costs, and insufficient attention (Oakley, 1990). Furthermore, companies are exploring means to solve the problem of unclear relationships and distinctions between design teams and other groups in order to avoid serious consequences such as financial losses, wasted time, and failed NPD projects. This means that the importance of efficiently managed design to new product success is becoming more widely recognized (Bruce & Bessant, 2002) and is fueling a new level of interactions between design and other functions involved in NPD.

Against this background, companies are seeking new criteria for managing design teams in a cooperative work environment. To create the right climate for cross-functional teamwork that includes a design team, managers first need to rely on the influence of the integrated design team in the NPD process. However, there are not many existing references that can be used to evaluate effective design cooperation or performance within cross-functional teamwork. Many researchers have introduced techniques such as cross-functional new product processes, quality function deployment and the enhancement of cross-functional communication in NPD (Brown & Eisenhardt, 1995; Pinto & Pinto, 1990; Cooper & Kleinschmidt, 1986). Yet, they have not discussed the performance or functional integration of design teams in NPD.

To help overcome this limitation, this study examines cross-functional cooperation with design teams as an important issue in improving the process and outcome of NPD. In the following sections, this paper reviews the role and process of design as it relates to cross-functional cooperation in NPD and the existing critical factors affecting cross-functional cooperation in NPD. Following that, empirical research based on a cross-section of departments in global consumer electronics organizations will be discussed. Finally, eleven critical success factors of cross-functional teamwork involving a design function will be identified and results presented showing the positive impact of these factors on the performance effectiveness of NPD.

The Role of Design in NPD

The role of design in business has generally been described as a professional service of creating and developing concepts and specifications to optimize the function, value and appearance of corporate products. Depending on which stage of the NPD process a design team is involved in, its role can range from helping in the generation and ideation of innovative product concepts to defining and representing the form (including the aesthetics) given to an emerging product (Veryzer and Mozota, 2005). But, nowadays, design activity is essentially characterized as involving compromise, choice, creativity and complexity in the new product development process. Also, as a functional element in the NPD process, design teams are defined as having a close link with marketing and technology teams (Cooper & Jones, 2002; Olson, 1993).

In the past, designers were responsible for the form and the visual aspects of a product: after making significant decisions in the upstream process, the role of design was rarely delineated in representations of the product development process. However, in a customer-based business paradigm, an understanding of costumers and new market trends is driving the role of the in-house design team to be one that is involved in developing the emotional dimensions of products and services (Leonard-Barton & Rayport, 1997). Furthermore, the current role of design in NPD is that of an integrator, as it is subsumed in many of the activities that make up the process and thus must negotiate with other functional specialists in order to achieve successful new product development (Perks, Cooper, & Jones, 2005).

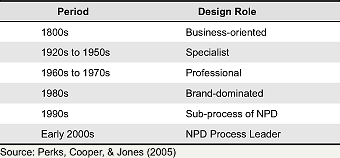

Table 1. The evolution of the role of design in NPD

The design team is now in a position to suggest the various alternative design treatments to be considered in cooperation with other functional teams. Moreover, the design team can undertake a leadership role in the NPD process, acting as a catalyst in the process of making efficient, effective and smooth decisions along with other functional specialists in an environment of cross-functional cooperation (CFC) (Rothwell & Whiston, 1990). This means that designers can carry out a broad array of tasks beyond those demanded by specific design activities (Von Stamm, 2003), and that the responsibilities of design teams should expand to encompass roles (e.g., the roles of interpreter, coordinator, and facilitator) that support the whole NPD effort (Turner, 2003). Thus, the responses of these design teams involve important issues that relate to achieving high NPD performance.

CFC with Design Teams in NPD

Nevertheless, many companies tend not to think about how they can integrate their other departments with their product design teams (Paton, 2005): they believe that the impact of integrating the design process in NPD performance is conditional. But design can be a bridge between technological expertise and customer needs in the NPD process and a central activity connected with other functions. Moreover, the design process results in new information gained through the synthesis, analysis and creative work that are undertaken as part of an integrated value-adding process (Hart, 1995).

On the other hand, in order to play an integrative role in overall product development, design teams need to take into consideration the contributions of other special functional groups (Brown & Eisenhardt, 1995). An integrated design team is highly interdependent, working with other corporate teams in its endeavors, and necessitates close interfacing with marketing, production, R&D (research and development), and other groups (Mozota, 2003). For these reasons, the design process should be included in any cross-functional collaboration, as it is a process that calls for combining diverse information from various functional groups.

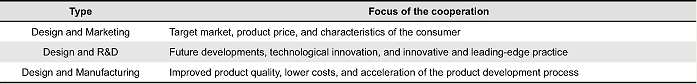

The cross-functional collaboration between the design team and other groups can be summarized in three parts: marketing, R&D, and manufacturing (Holland, Gaston, & Gomes, 2000; Ruekert & Walker, 1987; Perry & Sanderson, 1998). First, some researchers have explored the design and marketing interface and have concluded that there ought to be continuous interaction between marketing and design. Not only do designers need to know the product, the competition, the target market and the price, they also need information on the characteristics of the consumer and to be regularly updated on changes in consumer needs. This information must be clearly presented and available at all times, and must be appropriate to the needs of the designers (Slade, 1989).

Secondly, as with the marketing interface, it is recommended that there should also be regular contact between design and R&D. Designers need to be able to consult with R&D personnel, who themselves also need to communicate with groups involved in market research and in new product marketing that may be developed in the future (Hopkins, 1981). R&D information is essential to designers working on product design development; they need to know what is happening at the forefront of technology in terms of materials, machines and manufacturing methods. Such knowledge feeds the creative process and enables designers to develop innovative and leading-edge products.

Finally, companies are increasingly recognizing that integrating design and manufacturing contributes to improved product quality, lower costs, and acceleration of the product development process (Coughlan, 2002). For example, a report by the DTI (Department of Trade and Industry in the UK) emphasized that information about the design of a product is beneficial to production and manufacturing from the beginning of the product development process and that there needs to be continuous interaction between manufacturing and design (Rosenthal & Tatikonda, 1992; Francis & Winstranley, 1988).

However, a cross-functional team is a group of employees drawn from various functional areas of an organization, such as from engineering, marketing, design, human resources, and operations (Gabrielsson, 2002; Pinto & Pinto, 1990): the cooperation between the design team and these other groups must become a single collaborative network that works to develop solutions for present and future market opportunities. The challenge of developing successful new products requires an inter-functional approach across all the key disciplines involved in NPD (Griffin, 1997; Song, Montoya-Weiss, & Schmidt, 1997; Cooper & Kleinschmidt, 1995; Roberts, 1995).

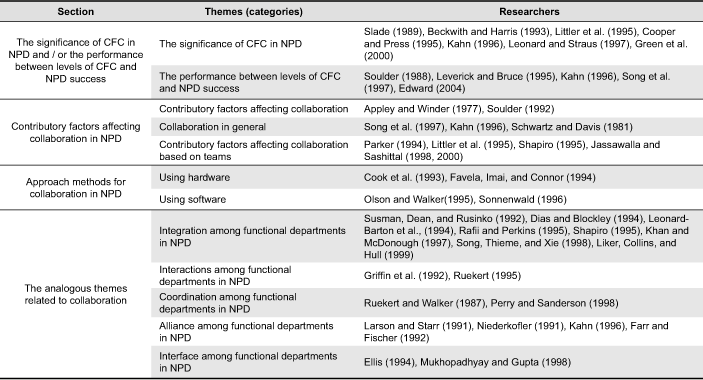

Table 2. Types of cooperation between the design team and other groups in NPD

In this view, the design process can be seen as a reiteration of the need for multiple convergent work in NPD. Furthermore, even if the cross-functional team is used for many different team types, the principal role of the design team may be to act as a liaison between these functional teams in the collaborative relationships among various functional groups (Mozota, 2003).

Critical Factors Affecting Successful CFC in NPD

For more than a decade, researchers have explored the benefits of eliminating organizational boundaries between participants in the NPD process (see Appendix 1). Griffin (1997) found that effective implementation of cross-functional teams “is crucial to success,” but commented, “we have not yet been able to define the organization and infrastructure which best supports effective multifunctional teams over time and across projects.” This review sets out to explore the critical success factors for cross-functional teamwork.

A survey of 43 Fortune 500 companies in the US revealed six major obstacles impeding the effectiveness of cross-functional cooperative teamwork. The key issue, affecting 80% of

respondents, was the tension that exists between team goals and functional priorities, surfacing in the form of: conflicting organizational goals; competition of resources; overlapping responsibilities; conflicting personal goals; a lack of clear direction or priorities; and a lack of cooperation (Wall & Lepsinger, 1994). Holland et al. (2000) investigated the critical issues for cross-functional teamwork in NPD by using Cohen and Bailey’s heuristic model of team effectiveness, which provided a useful framework for content analysis of the literature. This model categorizes the critical issues into six categories: task design, group composition, organizational context, internal processes, external processes, and group psychosocial traits. Hauptman and Hirji (1996) investigated the processes in a study of 50 concurrent engineering teams. In general, these empirical studies have focused on the creation of the right relationships among teams during the cooperative process to achieve optimal balance and control (Denison, Hart, & Kahn, 1996; Pinto & Pinto, 1990; Kline, McLeod, & McGrath, 1996; Henke, Krachenberg, & Lyons, 1990; Donnellon, 1993). Hence, successful cross-functional cooperation in NPD means achieving high performance through effective multi-functional teamwork. However, in reviewing the existing research it is difficult to identify the critical factors affecting the relationship between design teams and other groups in cross-functional cooperation, and there is little evidence-based guidance on how to achieve effective cross-functional teamwork with design teams. This limitation leads this researcher to identify these critical factors and to prove the effectiveness of these factors in NPD performance.

Methodology

The research presented herein aims to empirically explore the nature of cross-functional cooperation with design teams within organizations. The specific objectives are (1) to identify the critical success factors in cross-functional cooperation with design teams in new product development; and (2) to determine the positive impact of these factors through correlation analysis on product development performance.

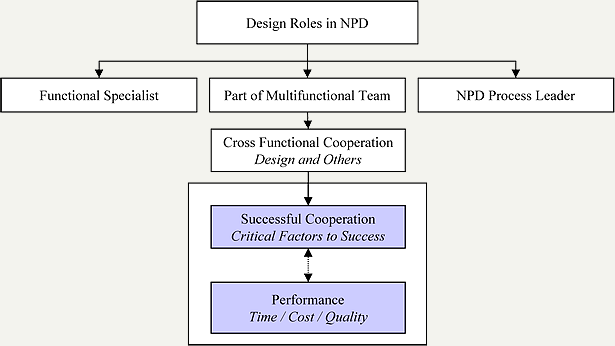

Figure 1. Research scope model.

This exploratory research was conducted using a four-phase iterative procedure. In developing each research method, the study embraced the grounded theory approach, a method for discovering theories or concepts directly from the data (Tayler & Bogdan, 1984).

First, to find existing factors that could be used as independent variables for the quantitative research, the related empirical research results were analyzed to reveal a substantial list of factors applicable to cross-functional cooperation in NPD. However, no critical success factors for cross-functional cooperation with design teams were discovered. Thus, reference was made to the eight main empirical studies that have set out the critical factors for general cross-functional teamwork (Appley & Winder, 1977; Schwartz & Davis, 1981; Soulder & Moenaert, 1992; Kahn, 1996; Littler, Leverick, & Bruce, 1995; Parker, 1994; Jassawalla & Sashittal, 2000; Shapiro, 1995), and the identification of the research variables was based on the results of these eight empirical studies.

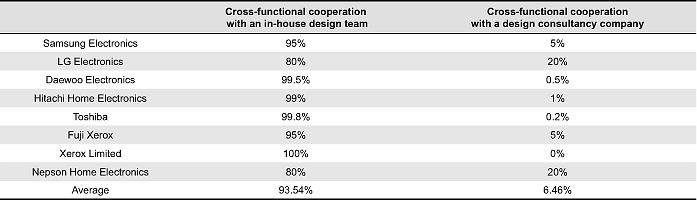

Second, following the recommendation of Song and Parry (1996), the list of 24 factors includes constructs and corresponding measurement items from the literature review needed to gather retrospective data based on a professional focus group panel (see Table 3). To verify the factors, an interview survey was conducted of 15 design-based managers of cross-functional NPD teams at eight global consumer electronics companies. The interview research was primarily used to discover the practical factors affecting successful CFC in the design teams of electronic consumer product companies. The research explored the performance measurement items for design teams and design management in practice by means of this interview survey.

Table 3. Organizational status of CFC in NPD

In the third phase, a total 105 factors (81 factors drawn from the literature and the 24 factors drawn from the interviews) was refined to 24 factors by using clustering and coding terms such as those used in synthesis analysis. This analysis was undertaken to simplify the large number of factors (24 in all) that still showed a relationship with each other (see Appendix 2): these 24 factors were highlighted as contributory factors affecting CFC with design teams in NPD.

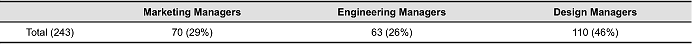

Finally, based on these variables, the quantitative research was undertaken using a questionnaire survey to determine the positive influence of design teams on cross-functional teamwork in NPD. The questionnaire was designed with four categories: personal and background information (five questions); identifying the priority of the 24 contributory factors; measuring the level and performance of cross-functional collaboration based on a recent new product development (nine questions); and discovering opinions about design performance and about the importance of design in cross-functional cooperation in NPD. Respondents were asked to indicate the answers on a 7-point scale. The questionnaire was pre-tested by six academic experts in design management and eight design managers who work for consumer electronics firms. The survey research followed the modification methods of Song et al. (1997). A total of 420 surveys sent by mail resulted in a total response of 243 usable questionnaires (representing a 60.75% response rate). The responses of the managers, drawn from eight global consumer electronics companies in Japan, Korea and the UK, were collected by directly visiting the companies (see Table 4).

Table 4. The proportion of responses from various managers involved in CFC

Operationability and Reliability of Constructs

For the data analysis, this research first used the analysis of principal components to identify the factors from the empirical analysis. In the second step, an independent T-test analysis was used to determine the differences in opinion regarding the degree of importance of each factor between the design managers (the design group) and the engineering and marketing managers (the non-design groups). Finally, to determine the contribution of the design team toward the success of cross-functional teamwork in NPD, regression and correlation analyses were used.

Most significantly, this research supported the use of measurement tools used in product development performance as a means to define the independent variables of the analysis. Many studies have developed measurement tools and methods for managing product development performance (Kochhar, Kennerley, & Davies, 1994, Maskell, 1991, Gregory, 1993, Globerson, 1985, Gupta & Wilemon, 1995). Measures to determine the given constructs of the critical success factors and performance were thus adapted from previous studies concerning cross-functional cooperation in NPD. However, existing measurement tools focus very much on the strategic level, with minimal involvement from the designers and developers of the products, and there is little evidence of work that examines performance in the context of product design and product design development (Veryzer, 1998).Because of this limitation, this study followed the research results of Pawar and Driva (1999), who present five categories of measurement items—time, cost, quality, flexibility, and management—from 30 possible items for measuring the performance of product design project teams. Along with these items, this study also took into consideration the measurement methods for product development performance used by the companies Europe Xerox and Fuji Xerox, which were determined from the results of in-depth interviews. The interviewees were asked to grade their product development performance (with regard to time, cost and quality) on a scale of one to seven, with seven representing perfect performance. Finally, three criteria were used to evaluate the success or failure of a new product development project: effective process management, based on a time objective; return on investment, based on a cost objective; and maintenance of competitive position in current markets, based on a quality objective. This study considered the relationships between the determinants of performance (independent variables), a statistical technique for amalgamating, summarizing, and reviewing previous quantitative research. The regression analysis model contains the dependent variable of product development performance and the independent variables of the critical factors affecting successful cooperation with design teams in NPD. Variance inflation factors and tolerance statistics did not indicate any multi-collinearity among the independent variables. This supports the appropriateness of regression, as well as the contention that interaction and collaboration should be considered unique processes.

Analysis

Identification of the Critical Factors

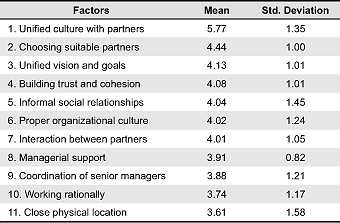

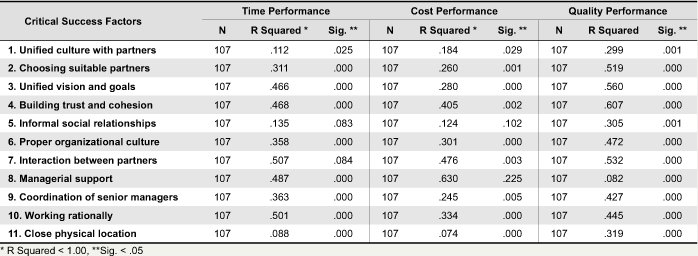

The results of factor analysis (using the extraction method of principal component analysis) suggested 11 factors as being the most reasonable factor groups to consider as affecting cross-functional cooperation among the 24 factors in descending order of importance. Also, the results show the eigenvalues in terms of the percentage of variance explained. The 11 factors with eigenvalues over 1 explain 55.7% of the total variance. The degree of importance of each factor affecting CFC was calculated by means of the mean value of each factor affecting cross-functional cooperation, which then produced the priority given to each item. The degree of importance of each factor was measured as ordinal data. Importance was ranked from one to seven, with degree one representing a level of little importance in affecting cross-functional cooperation in NPD, and degree seven representing an extremely important factor. The average total degree of importance was 5.0.

Table 5 presents the arithmetic mean—the sum of all the members on the list divided by the number of items on the list—and the standard deviation, which describes the spread of the data. The mean describes the central location of the 11 critical success factors. The value of each of the eleven factors was calculated by finding the mean value. “Unified culture with partners” was viewed as the most important critical success factor by all executives. Similarly, among the top five important critical success factors were “choosing suitable partners,” “unified vision and goals,” “building trust and cohesion,” and “informal social relationships.” “Working rationally” and “close physical location” did not appear to be very important in the implementation process for these companies.

Table 5. Mean ranking of critical factors by degree of importance in CFC for NPD

In Table 5, it can be seen that “unified culture with partners,” “choosing suitable partners” and “proper organizational culture” are important success factors for the design group. In these results, there is no doubt that “relationships” and “culture” are the most important issues for designers when it comes to cross-functional cooperation, culture meaning common language and common geographic and ethnological conditions in the organization. To build a good relationship and a common culture with others, a designer needs to understand the other languages used in managerial situations in the company. In the 1970s, anecdotal evidence indicated that perceived NPD project “success” depended more on behavioral skills than technical skills. Moreover, recent evidence shows that cooperative behavior with members is predictive of successful outcomes (Monczka, Petersen, & Handfield, 1998). In conclusion, building cooperative behavior in a common culture is one of the important issues for improving cross-functional design performance and for leading successful cross-functional teamwork with designers.

Differences in CSFs between a Design Group and a Non-design Group

To understand the significant factors in more detail, the factor differences between a design group (design-based managers) and a non-design group (marketing and engineering-based managers) were analyzed. This in turn may serve as a useful guide for firms in the process of implementing a cooperative NPD system. The primary contribution of this study is the empirical identification of critical success factors for cross-functional cooperation in NPD, and the identification of differences in critical factors that companies need to consider for a design group in the CFC process compared with a non-design group.

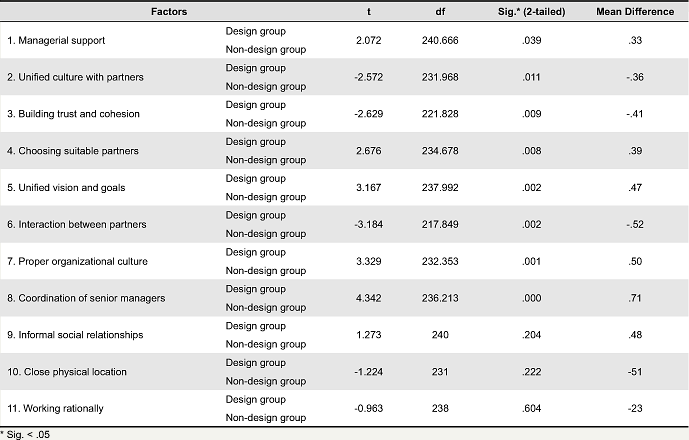

This research evaluated the data through T-test analysis, which was used to prove the validity of the value difference of each group and to determine whether there was a significant difference between the two sets of scores. Table 6 shows the independent T-test results. Three factors—“informal social relationships,” “close physical location,” and “working rationally”—were identified as factors with no significant differences in comparison between the two groups: using two-tail significance, the equal variance estimates used to determine whether type differences exist was over .05.

Table 6. Independent T-test for equality of means

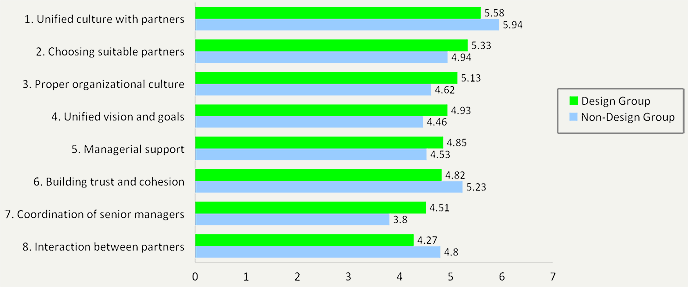

Based on the T-test results, Figure 2 shows the eight comparative critical factors between the design group and the non-design group. Most importantly, the critical factors for the design group were “unified culture with partners,” “choosing suitable partners,” and “proper organizational culture.” For the non-design group, “unified vision and goals,” “building trust and cohesion,” and “choosing suitable partners” were in the top ranking. From Table 6, it can be seen that “unified culture with partners” and “choosing suitable partners” were the most important CSFs for both groups. In the case of the design group, the design managers believed that “choosing suitable partners” made for successful cross-functional cooperation in NPD. By contrast, the marketing and engineering managers (the non-design group) indicated that “building trust and cohesion” was a higher priority success factor for cross-functional cooperative NPD teams.

Figure 2. Comparison of CSFs between a design group and a non-design group (number unit: mean value)

The Effects of the Factors on Product Development Performance

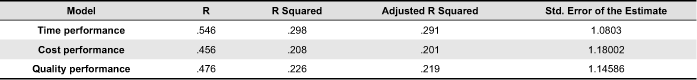

It has been verified that there is a positive linear relationship between the factors and performance in NPD. To apply this hypothesis to the relationship between a design team and other groups, multiple regression analysis with a forward method was used. In the forward method, the first variable considered for entry into the equation is the one with the largest positive or negative correlation with the dependent variable. Based on the descriptive statistics of this multiple regression analysis, Table 7 shows that time performance accounts for 29.8% of variability with regard to satisfactory CFC with design teams. Cost performance variability accounted for 20.8% and quality variability was recorded at 22.6%. The person correlation value indicated 0.546 for time performance, 0.456 for cost performance, and 0.476 for quality performance, meaning that there is a positive correlation between the cross-functional cooperation with a design team and each instance of product development performance. As the results show, time performance had the highest rate of effectiveness among the correlations.

Table 7. Regression analysis between the level of the 11 factors and performance

These 11 factors were found by means of giving a criterion of 95% probability of multiple regression analysis within a hierarchical method. From the output of these correlation values, we can conclude that there is a positive correlation between the factors and performance. The correlation between each paired factor affecting cross-functional cooperation can be found from the correlation values in Table 8.

Table 8. Correlations from multiple regression analysis

By analysis of each factor, this study suggests the evident correlations and coefficients between the factors and performance. For improving time performance in cross-functional cooperation with design teams, the important factors are “interaction between partners” and “working rationally.” “Managerial support” is the most important factor in improving cost performance. Finally, the results show that high-quality design performance comes from “building trust and cohesion” and “unified vision and goals” in cross-functional cooperation of NPD.

Overall, the findings from this analysis show that unifying the common culture between the design group and other functional groups promotes high-performance success, and cross-functional cooperation in NPD with design teams makes for high performance with regard to time effectiveness. These findings indicate that the elements of cooperation with a design team correlate to greater performance success, providing tentative evidence that the NPD process has a role as a component of integration with a design team, though this role may be secondary to cooperation activities. This evidence also tentatively supports the proposed multidimensional view of integration with a design team. This article examines the relationships and the design influence of cross-functional teamwork in the NPD process. There are two clear results: first, the results identify the critical factors affecting successful cross-functional cooperation with a design team in NPD. In summary, the key success factors include “unified vision and goals,” “unified culture with partners,” and “building trust and cohesion,” showing that design co-work requires improvements in the climate of the work environment, beyond those that support the system or infrastructure. Managers must consider the factors as the collaborative conditions before embarking on a collaborative strategy for successful product development. The differences between the design groups and the non-design groups highlight that the more important issues relate to managing the design team in the collaboration process. Second, this research empirically proves the positive impact of cooperation with design teams on product development performance. Design increases NPD performance and creates the value of the NPD processes and teams (Cooper & Press, 1995; Hollins, 1990; Baxter, 1995; Mozota, 1990). Cross-functional teamwork with functional design teams is a path towards efficient product development.

Conclusion

The results of this study identify the success factors for cross-functional cooperation in NPD and determine the positive impact of these factors on product development performance. The relationships among design, marketing, and other disciplines involved in NPD are complex; how these functions are integrated in new product development can have a significant impact on the product that ultimately results from the process, and thus on the product’s subsequent success or failure.

Different teams or departments with different roles that encounter conflicts often try to stick to their own viewpoints and aims. Different departments seek different objectives, ones which do not necessarily coincide with the objectives set out for the firm: consequently, the parties are unable to come to an understanding and can only argue with each other. To overcome this kind of conflict situation, managers have to set up rules that will motivate employees around a common vision and goal, and to define a clear project strategy and a role for each function at each step. To manage cooperation within design teams, managers need to rely on the informal power or influence that the integrated design group has developed within the firm. The integrated design team is usually a minority both in numbers and in culture within the NPD team. As a result, it tends to fall into conflict with the majority, who put pressure on it to conform. Managing the NPD process means raising the awareness of the project leader with regard to these issues in order to foster cooperation.

The significance of this research may alter to some degree from factor to factor and among different industries and companies, because the research was conducted with a specific focus on the consumer electronics industry sector. However, there is no doubt that the effective implementation of cross-functional teams is critical to new product success. Recent NPD processes have compelled designers to work more closely with other functional groups: new product development managers should consider the changing nature of competition that results from industry evolution while developing strategies that encompass the use of design functions in new product development (Holland et al., 2000; Griffin, 1997; Cooper & Kleinschmidt, 1995; Roberts, 1995). To support these challenges, this paper suggests the significance and validity of using the design function in cross-functional teamwork and indicates what the critical issues are when it comes to managing the integrated design team in an atmosphere of cooperation.

References

- Appley, D. G., & Winder, A. E. (1977). An evolving definition of collaboration and some implication for the world of work. Journal of Applied Behavioural Science, 13(3), 279-281.

- Baxter, S. (1995). Product design. London: Chapman & Hall.

- Beckwith, D., & Harris, D. (1993). The mega-team design process: Adding a new dimension to concurrent development. Design Management Journal, 4(4), 69-77.

- Brown, S. L., & Eisenhardt, K. M. (1995). Product development: Past research, present findings, and future directions. Academy of Management Review, 20(2), 343-378.

- Bruce, M., & Bessant, J. (1995). Design in business. London: Pearson Education.

- Cook, S. D. N., & Yanow, D. (1993). Culture and organizational learning. Journal of Management Inquiry, 2(4), 373-390.

- Cooper, R. G., & Jones, T. (2002). Informing design decision-making in new product development: Firming up the fuzzy front end. Salford, UK: University of Salford, Centre for Design Manufacture and Technology.

- Cooper, R. G., & Kleinschmidt, E. J. (1995). Benchmarking the firm’s critical success factors in new product development. Journal of Product Innovation Management, 12(5), 374-391.

- Cooper, R. G., & Kleinschmidt, E. J. (1986). An investigation into the new product process: Steps, deficiencies, and impact. Journal of Product Innovation Management, 3(2), 71-85.

- Cooper, R., & Press, M. (1995). The design agenda: A guide to successful design management. Chichester, UK: John Wiley & Sons.

- Coughlan, P. (2002). Managing design: An operations management perspective. In J. R. Bessant & M. Bruce (Eds.), Design in business: Strategic innovation through design (pp.36-58). London: Pearson Education.

- Denison, D. R., Hart, S. L., & Kahn, J. A. (1996). From chimneys to cross-functional teams: Developing and validating a diagnostic model. Academy of Management Journal, 39(4), 1005-1022.

- Dias, W. P. S., & Blockley, D. I. (1994). The integration of product and process models for design. Design Studies, 15(4), pages 417-433.

- Donnellon, A. (1993). Crossfunctional teams in product development: Accommodating the structure to the process. Journal of Product Innovation Management, 10(5), 377-392.

- Edward, P. L. (2004). Speeding, terrorism, and teaching to the test. Quarterly Journal of Economics, 121(3), 1029-1061.

- Ellis, G. (1994). How culturally appropriate is the communicative approach? ELT Journal in Oxford Journals, 50(3), 213-218.

- Farr, C.M., & Fischer, W.A. (1992). Managing international high technology cooperative projects. R&D Management, 22(1), 55-68.

- Favela, J., Imai, K., & Connor, J. J. (1994). Hypermedia support for collaborative design. Engineering with Computers, 9(3), 125-132.

- Francis, A., & Winstanley, D. (1988). Managing new product development: Some alternative ways to organize the work of technical specialists. Journal of Marketing Management, 4(2), 249-260.

- Gabrielesson, A. (2002). Cross-functional co-operation and networking in industrial settings—With special focus on the product realization process. Unpublished doctoral dissertation, Royal Institute of Technology, Stockholm, Sweden.

- Globerson, S. (1985). Developing a performance criteria system. International Journal of Production Research, 23(4), 639-646.

- Green, S. G., McComb, S. A., & Compton, W. D. (2000). Promoting effective linkages between cross-functional teams and the organization. Advances in the Management of Organizational Quality, 5(1), 29-70.

- Gregory, M. J. (1993). Integrated performance measurement. International Journal of Production Economics, 30-31, 281-296.

- Griffin, A. (1992). Patterns of communication among marketing, engineering and manufacturing: A comparison between two new product teams. Management Science, 38(3), 360-372.

- Griffin, A. (1997). PDMA research on new product development practices: Updating trends and benchmarking best practices. Journal of Product Innovation Management, 14(6), 429-458.

- Gupta, A. K., & Wilemon, D. (1996). Changing patterns in industrial R&D management. Journal of Product Innovation Management, 13(6), 497-511.

- Hart, S. (1996). Small business marketing. In M. Warner & J. P. Kotter (Eds.), International encyclopedia of business and management (Vol. 4, pp. 3624-3649). London: Thomson Learning.

- Hauptman, O., & Hirji, K. K. (1996). Corporate culture: From vicious to virtuous circles. London: Hutchinson Business Books.

- Henke, J. W., Krachenberg, A. R., & Lyons, T. F. (1993). Cross-functional teams: Good concept, poor implementation. Journal of Product Innovation Management, 10(3), 216-229.

- Herbruck, D., & Umback, S. (1997). Design management and new product development: Linking people and process. Design Management Journal, 8(2), 44-49.

- Holland, S., Gaston, K., & Gomes, J. (2000). Critical success factors for cross-functional teamwork in new product development. International Journal of Management Reviews, 2(3), 231-259.

- Hollins, B., & Pugh, S. (1990). Successful product design. London: Butterworkth.

- Hopkins, D. S. (1981). New product winners and losers. Research Management, 24(3), 12-17.

- Jassawalla, A. R., & Sashittal, H. C. (2000). Cross-functional dynamics in new product development. Research Technology Management, 43(1), 46-49.

- Kahn, K. B. (1996). Interdepartmental integration: A definition with implications for product development performance. Journal of Product Innovation Management, 13(2), 137-151.

- Khan, K. B., & McDonough, E. (1997). An empirical study of the relationships among co-location, integration, performance, and satisfaction. Journal of Product Innovation Management, 14(3), 161-178.

- Kline, T. J. B., McLeod, M., & McGrath, J. L. (1996). Team effectiveness: Contributors and hindrances. Human Systems Management, 15(3), 183-186.

- Kochhar, A. K., Kennerley, M., & Davies, A. (1994).

A framework for performance indicators in manufacturing control systems. In Proceedings of the 1st International EurOMA Conference (pp. 85-93). Cambridge, UK: Cambridge University Press. - Larson, A., & Starr, J. A. (1991). A network model of organization formation. Entrepreneurship Theory and Practice, 17(2), 5-19.

- Leonard, D., & Straus, S. (1997). Putting your company’s whole brain to work. Harvard Business Review, 75(4), 110-21.

- Leonard-Barton, D., Bowen, H. K., Clark, K. B., Holloway, C. A., & Wheelwright, S. C. (1994). How to integrate work and deepen expertise. Harvard Business Review, 72(5), 121-130.

- Leverick, F., & Bruce, C. (1995). Partnerships in the motor industry: Opportunities and risks for suppliers. Long Range Planning, 31(1), 72-81.

- Liker, J. K., Collins, P. D., & Hull, F. M. (1999). Flexibility and standardization: Test of a contingency model of product design-manufacturing integration. Journal of Product Innovation Management, 16(3), 248-267.

- Littler, D., Leverick, F., & Bruce, M. (1995). Factors affecting the process of collaboration product development: A study of UK manufactures of information and communications technology products. Journal of Product Innovation Management, 12(1), 16-32.

- Maskell, B. H. (1991). Performance for world class manufacturing. Cambridge, MA: Productivity Press.

- Monczka, R. M., Petersen, K. J., & Handfield, R. B. (1998). Success factors in strategic supplier alliances: The buying company perspective. Decision Sciences, 29(3), 553-577.

- Mozota, B. B. D. (1990). Design as a strategic management tool. In M. Oakley (Ed.), Design management: A handbook of issues and methods (pp.73-84). Oxford: Basil Blackwell.

- Mozota, B. B. D. (2003). Design management: Using design to build brand value and corporate innovation. New York: Allworth Press.

- Mukhopadhyay, S. K., & Gupta, A.V. (1998). Interfaces for resolving marketing, manufacturing and design conflicts. European Journal of Marketing, 32(1), 101-124.

- Niederkofler, M. (1991). The evolution of strategic alliances: Opportunities for managerial influence. Journal of Business Venturing, 6(4) 237-257.

- Olson, E. M. (1993). Perceptual differences in

interdependence, conflict, and conflict resolution between design and other functions involved in new product development. In Proceedings of the 5th International Forum on Design Management Research and Education (pp. 1-18). New York: MIT. - Olson, E. M., & Walker, O. C. (1995). Organizing for effective new product development: The moderating role of product innovativeness. Journal of Marketing, 59(1), 48-62.

- Parker, G. M. (1994). Cross-functional collaboration. Training & Development, 48(10), 49-52.

- Parton, M. Q. (1990). Qualitative evaluation and research methods. Newbury Park, CA: Sage Publication.

- Pawar, K. S., & Driva, H. (1999). Performance measurement for product design and development in a manufacturing environment. International Journal of Production

Economics, 60-61, 61-68. - Perks, H., Cooper, R., & Jones, C. (2005). Characterizing the role of design in new product development: An empirically derived taxonomy. Journal of Product Innovation Management, 22(2), 111-127.

- Perry, M., & Sanderson, D. (1998). Cording joint design work: The role of communication and artifacts. Design Studies, 19(3), 273-287.

- Pinto, M. B., & Pinto, J. K. (1990). Project team communication and cross functional cooperation in new product development. Journal of Product Innovation Management, 7(3), 200-212.

- Rafii, F., & Perkins, S. (1995). Cross functional integration: Moving beyond physical co-location. Design Management Journal, 6(3), 64-71.

- Rassam, C. (1995). Design and corporate success. Aldershot, UK: Design Council.

- Roberts, E. B. (1995). Benchmarking the strategic management of technology Π. Research Technology Management, 38(2), 18-26.

- Rosenthal, S., & Tatikonda, M. V. (1992). Competitive advantage through design tools and practices: Integrating design and manufacturing for competitive advantage. Oxford: Oxford University Press

- Rothwell, R., & Whiston, T. G. (1990). Design, innovation and corporate integration. R&D Management, 20(3), 193-201.

- Ruekert, R. W. (1995). Upper management control of new product development projects and project performance. Journal of Product Innovation Management, 19(3), 233-245.

- Ruekert, R. W., & Walker, O. C. (1987). Marketing’s interaction with other functional units: A conceptual framework and empirical evidence. Journal of Marketing, 51(1), 1-19.

- Schwartz, H., & Davis, S. M. (1981). Matching corporate culture and business strategy. Organisational Dynamics, 10(1), 30-48.

- Shapiro, B. P. (1995). Functional integration: Getting all the troops to work together. Harvard Business School Note, 9(5), 87-122.

- Slade, M. E. (1989). The fictitious-payoff function: Two applications to dynamic games. Annales d’Econometrie et de Statistique, 15(16), 193-216.

- Song, X. M., & Parry, M. E. (1996). What separates Japanese new product winners from losers. Journal of Product Innovation Management, 13(5), 422-439.

- Song, X. M., Montoya-Weiss, M. M., & Schmidt, J. B. (1997). Antecedents and consequences of cross-functional cooperation: A comparison of R&D, manufacturing, and marketing perspectives. Journal Product Innovation Management, 14(1), 35-47.

- Song, X. M., Thieme, R. J., & Xie, J. H. (1998). The impact of cross-functional joint involvement across product development stages: An exploratory study. Journal of

Product Innovation Management, 15(4), 289-303. - Sonnenwald, D. H. (1996). Communication roles that support collaboration during the design process. Design Studies, 17(3), 277-301.

- Soulder, W. E. (1988). The role of project target clarity in an uncertain project environment. International Journal of Operations & Production Management, 24(12), 1269-1291.

- Soulder, W. E., & Moenaert, R. K. (1992). Integrating marketing and R&D project personnel within innovation projects: An information uncertainty model. Journal of Management Studies, 4(29), 485-512.

- Susman, G. I., Dean, J. W., & Rusinko, C. A. (1992). Facilitating integration between design and manufacturing. Design Management Journal, 3(1), 71-76.

- Tayler, S. J., & Bogdan, R. C. (1984). Introduction to qualitative research methods: The search for meanings. New York: John Wiley & Sons.

- Turner, R. (2000). Design and business: Who calls the shots? Design and Management Journal, 11(3), 42-27.

- Von Stamm, B. (2003). Managing innovation, design and creativity. Chichester, UK: Wiley & Sons.

- Veryzer, W. R. (1998). Discontinuous innovation and the new product development process. Journal of Product Innovation Management, 15(4), 304-321.

- Veryzer, W. R., & Mozota, B. B. D. (2005). The impact of user-oriented design on new product development: An examination of fundamental relationships. Journal of Product Innovation Management, 22(2), 128-143.

- Wall, S., & Lepsinger, R. (1994). Cross-functional obstacles. Training, 5(2), 125-126.

- Walsh, V., Roy, R., Bruce, M., & Potter, S. (1992). Winning by design. Oxford: Blackwell.

Appendix

Appendix 1. Overview of literatures related to CFC in NPD

Appendix 2. PCA of possible determinants of attachmen